![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

I want something to turn reclaimed timber into new and more useable timber where the wood is facing view and I don't want dented and scared rustic looks. It will be used for old scaffold board, pallet wood, 'skip find' roof timbers and the like.

The reviews seem to rate the Makita 2012NB/2 Thicknesser which is just under £500 so pretty much on the top end of budget.

Anything wrong with that choice?

No, I don't want to hand plane everything but anything else I should be considering?

Peter Millard tested this one...

It will be used for old scaffold board, pallet wood, ‘skip find’ roof timbers and the like.

Can't help but feel that you'll spend a lot of time and money replacing chipped blades...

Yes, I just asked the chippys at work and they said the same thing...

Chippys are right if you are working against the clock, not so right if you are working for free and want to save money. Just got to be thorough removing the screws and nails.

EPT1500 - Disconinued now by screwfix/B&Q

I'm considering something similar. I gave one at work but I'd don't want to be so limited.

As much as I'd like to trust my ability to discover all metallic debris on the timber, I'm not as confident as you that it would be possible.

Yeah I'm scared to death of using reclaimed wood on the planer.

Tiniest little bit of metal or ingrained stone where it's been kicking about on the floor and that's it. Track marks down every piece 😭

If you're not doing too much and not taking off loads, would maybe a drum sander with a feed do it?

As much as I’d like to trust my ability to discover all metallic debris on the timber

That's the trouble. It's not always and quite often not, metallic.

Stones in the end of boards are the classic where it's been leant against a wall with the end plonked on the ground.

If you're set on a planer, you might look at the Triton one?

I actually have an old really knacked planner for just this task. Clean wood with a wire brush on a grinder. Get all nails out. Results are ok but the baldes are obviously not in the best shape. Gets the wood dimensionalised well though but the finish is far from perfect.

Long story short. Get a second hand one that you don't have to worry about as much or at least two sets of blades. Good ones and I don't care ones

I once put some sleepers through my resaw with 60mm tooth pattern oh the bang it made hitting a bolt cost me new blade too

On don't skimp on thickness machines they need heft to handle the vibration. The Makita one is ok as is the DeWalt. I've got an old hand planer that I skim over the boards first if they are reclaimed the blades are cheap as chips on that. a cheap stud finder also helps to find hidden treasure.

I'm all for reusable timber it's slower grown and be better especially softwood.

My thoughts on jointer/thicknesser were based on this video which is a little dismissing of a drum sander :

I get the point about getting nicks in the planer blade, year ago I had a real cheap electric hand sander bought for me. I was going to use it to try and smooth some window sill planks and hit a small nail head on the very first pass. Yes, there rest were all beautifully striped rather than stripped. I hadn't thought about stones embedded but now am wondering how easy it is to swap blades on a combined planer/jointer. 1st pass on everything with the knickered blades and the proper finishing with the shiny straight blades.

Will google more before committing to anything

I don’t use pallet wood so can’t comment on that issue.

But I do have (a different branded version of) the erbauer above and whilst it’s ok, if I were buying again I’d spend more and get a thicknesser only, as per your makita pick.

I can tell you changing blades on that machine at least is a faff and required careful alignment.

Also, you’ll be wanting to look at chip extraction.

Just looked up the makita and it does indeed feature a “quick blade changing mechanism” praised by the review I just looked at. Maybe the A grade B grade blade plan could be a goer.

If it's a big enough nail, it can knacker the knife wedge and block too, given that the knives project a very small amount.

Seen that happen 😭😭😭

When I was the technician in the college furniture workshop we banned any reclaimed wood from our machinery.

Still had the odd person who would absolutely insist that it had been checked and double checked and triple checked.

Still ended up with chipped knives... 😭

I love reusing timber, but it really can be unkind to machinery.

I think if you get any board, chop a bit off each end, go over it with a metal detector, then take a pass or two with your scratty electric hand plane, then thickness it.

Should be ok.

Drum sander thicknesser type Sanders aren't thicknessers in the proper sense of course, but as you mentioned time wasn't an issue, I thought it might be an option. 😊

I'd be going for 2 cheap machines if the space allows. Or a finishing thicknesser and a hand electric planer with cheap to replace blades.

This type of machine is probably the next big piece I'd get. A mate had murmured about going halves. Mate take him up. Especially as I have more space so it'll likely end up living at mine.

I think the challenge with thicknessers and reclaimed wood (apart from the blade chipping) is the machine has a bit of a struggle with the first few and last few inches off the board and can take a bit of a bite out of them. Working with stuff like pallet wood - the boards are already short, if you need to cut 6" off each end after you've planed thicknessed them you're not really left with much.

The budget duel purpose ones like the Erbauer (fox make something similar and theres a few other 'own brand' machines around the same price point) are ok up to a point - they're probably all the same machine under the sticker - they can do both jobs, eventually, but theres a lot of fanny about getting from one set up to the other - theres a dust port / safety cover that you have to move and reposition either above or below the blade depending on what function you're using - theres a safety lockout as part of it which means the machine won't operate unless its attached (which given the OP's reputation can only be a good thing) but the guard is just a bit shitty and fiddly and ill-fitting and just difficult to work with. Adjusting the thicknesser depth isn't terribly accurate or repeatable and getting the blade and bed to run parallel is a fuss. You'll burn through a lot of wood trying to get the thing set up.

The blades are HSS rather than TCT and and correspondingly short lived. They're cheap and resharpenable - but again replacement and getting them all running true is another longwinded faff and another binbag or two of shavings

The fence on them is nowhere near adequate for squaring / jointing

I just binned mine - the guard cracked and wouldn't stay put and mean't the machine could cut out mid cut and spares weren't readily available I'd had ideas to use it making useful material out of a ton or so of oak barrel staves I had left over from a project. What I mostly got from it was an awful lot of whisky scented potpourri

If I had reason to get something similar again and I'd get a thicknesser only and use jigs with it if I to for surfacing

If you aren't in a rush and want to save money then you can do thicknessing with a router. If you Google "router thicknesser" then you'll find some commercial jigs and some DIY options.

"If you aren’t in a rush and want to save money then you can do thicknessing with a router. If you Google “router thicknesser” then you’ll find some commercial jigs and some DIY options."

I hate to imagine hitting a hidden nail with a router!

With a planer you'll break only the blade...

It will be used for old scaffold board, pallet wood, ‘skip find’ roof timbers and the like.

What size of end product are you aiming for? The whole planer/jointer/thicknesses process is about turning rough, irregular lumber into flat boards with square edges so that you can then glue and joint up into larger boards. Anything at all wonky and more that 3 or 4 feet long isn't going to get un-wonked by a little bench top planer

If you're using pre-milled timber that is already rectangular but needs to have s some bumps and bashes taken off the face of them - rather than change the size and shape of them then they really just need sanding. On a scaffold board scale - if the the things you are making are as big as scaffold boards rather than smaller items cut from those boards - a belt sander will do that pretty well - presuming what you're starting with is straight (until they dry out - but then it wont matter what you've done to plane them). If they're not straight then a planer thicknesser that size won't get them straight. On a smaller scale - pallet wood size - a linisher will do that really well - flatten out an uneven surface.

With the big pile of oak barrel bits above I gave up on the planer thickener and I used a friend's linisher to get one flat face on each stave (they're curved and angled on every face so you've no datum to square them up from. Once one face was flat it was easy to tidy up the other faces on a band saw or table saw. Usefully the linisher would give a nice shower of pretty sparks to warn you if theres a bit of metal in there rather than a bang and a wasted afternoon.

I hate to imagine hitting a hidden nail with a router!

With a planer you’ll break only the blade…

With a carbide tool it makes a few sparks but cuts through it pretty well. It might chip the cutter but doesn't always.

I've got a Triton that I used for a lot of the visible wood in the house like window boards and a clad wall and some shelves.

People are, rightly, quite precious of their planers and reluctant to have random stuff through. So I bought my own for the renovation, they were about £220 at the time.

Main reasons were it was the widest at that price point.

Didn't expect amazing, but it did good enough. More planer than thicknesser. Embedding it into a larger bench would probably improve its thicknessing credentials as its deck is a bit flexy. Probably wasn't helped by me putting 3m lengths through.

Annoyingly a sawmill friend acquired a big workshop planer a year after I finished the house 🙄

I’m all for reusable timber it’s slower grown and be better especially softwood.

I disantled a mahogany chest of drawers, it was absolutely knackered all the outer face was solid mahogany, the drawer bottoms were nice ash.

But the drawersides and back? spruce sitka by the looks of it, not a single knot. tight grain perfectly straight and properly quarter sawn.

So thats been set aside for guitar tops!

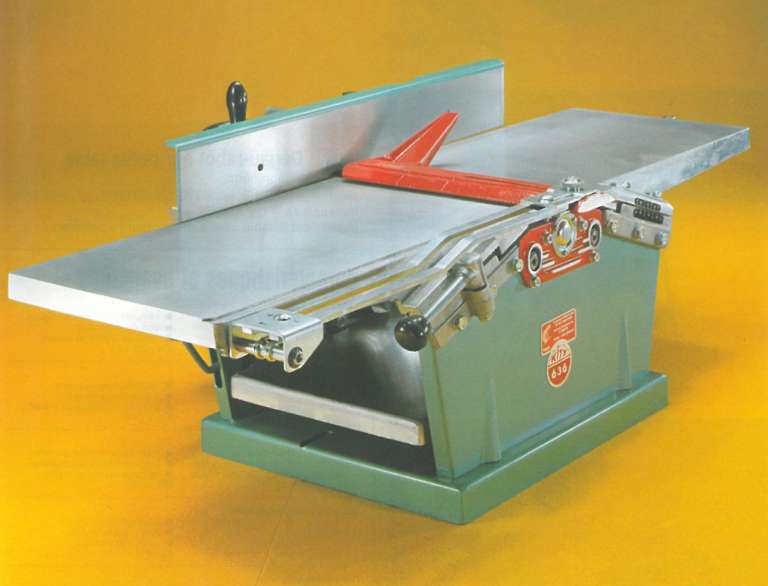

I had a 10" Clarke thicknesser for a while. Same as the Scheppach and various other equivalents. It was pretty crap really - flimsy chassis, poor grip on the wood, not enough adjustment to get it set up well, prone to overheating. I bought a secondhand Kity 636 a couple of years ago, and although it's the same sort of size, it's an infinitely better machine.

If you definitely want a new one, I think the Metabo HC260 is pretty good. Record Power do an equivalent.

Nails and screws wouldn't be my worry with used scaffold planks. Rather the ingrained sand from trodden-in mortar and concrete spills. The quartz grains will have a hardness far in excess of steel and will micro-chip or severely blunt your blades within seconds.

At the moment I run a wire brush in an angle grinder over the timber before I start using ot to get rid of stones and grit. This normally also exposes the slightly sunken nails that the first glance didn't reveal. After that, yes there is a risk of a deeply embedded and hidden nai;l/stone but I am willing to risk it.

I used a router and sled to flatten and then carve this. It was about a 4" slope one side to the other so took some time and made lots of chippings but I got there in the end.

I was thinking of the thicknesser to mostly do short lengths, so scaffold boards cut to the rough size I need rather than feeding 3.6m through each time.

I was tempted by the combination as the planer should give a straight reference edge from a slightly wavy or chipped rough edge.

Also looking for a drum sander that works like the combination thickness/planer and sands either freehand above or through the controlled slot below. Nothing nearby 2nd hand and hasn't been for ages.