![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

I figured out the other day that the cambelt in my car will likely outlive the car. It was replaced at 100k so the 2nd one will likely be 20 years old and 200k and I doubt the rest of the car will last to 2025).

But then I couldn't figure out why it had a cambelt (or chain) in the first place?

So I googled it, and all that comes up is a lot of American sites explaining why engines are still built with an OHV configuration still have pushrods rather than an OHC.

They obviously have limitations on small revvy petrol engines, but why did they disappear from diesels?

Double overhead valves mainly.

Push rods give good low end but lack at high end /lack revs also

See also block real estate

Valve train mass

And noise/smoothness of engine.

Pushrods in the modern world would be like turning up to the tdf with a Viking 9 speed

You get diesel pushrod engines, just not common in the UK.

mostly In torquey applications rather than civilian

Landrover's 300tdi was the last diesel pushrod engine?

I imagine that line boring of the camshaft in the push rod block and locating the bearings is an added production line hassle.

Struggling to think of the benefit for general purposes. Low down torque is not lacking in most diesel cars. Pushrods increase parts count, complexity, probably limit the modular design of the engine so increase costs when it comes to using the same core engine design but scaled for different capacities and cylinder counts, might cause issues with turbocharged applications, are not going to do anything to improve emissions or noise...the two principle design criteria of a modern car engine. Probably these and many other issues. All these tings have a cost vs benefit analysis done and push rod engines obviously lose out in an age where we're chasing ever more efficiency from engines.

Not sure how a pushrod is an improvement over a cam acting directly onto a hydraulic tappet then the valve.

Theres load of older engines

Nissan 2.7 that's in black cabs for starters

Land Rover 300 Tdi was an overhead cam, not a pushrod engine. Ironically (IIRC), the 300 Tdi was an update on the 200 Tdi requested by the military to allow easier access to the cam belt change.

Cannot confirm if it has an overhead cam as I don't have one

But the 300tdi absolutely has pushrods.

Same ones my 200tdi has.

PN 546799

No one really wants a car that sounds like a tractor again do they ?

Never going to happen, unless someone shed builds one, but i would love to see a deisel elec hybrid

Tiny 1ltr tdi engine, vw did a 3cyl version, plus tiny say 30kw elec pack

Plug in overnight to charge then alternate between elec or derv, with regen or trickle charge.

The range could be huge, great for mixed use driving say through a major city then on to motorway or open roads

Pushrods in the modern world would be like turning up to the tdf with a Viking 9 speed

I give you the chevrolet Ls series small block v8 - with the LT2 variant still used in the most recent corvette C8.

https://ls1tech.com/articles/2020-corvette-c8-why-no-dual-overhead-cam-engine-gm/

I give you the chevrolet Ls series small block v8 – with the LT2 variant still used in the most recent corvette C8.

I am aware of that. It's also the butt of many jokes about lack of innovation within that that particular company. It's also not a diesel.

Pushrods increase parts count, complexity,

I was under the impression pushrods resulted in simpler engines with less complexity? And also more compact overall engine size and generally weigh less too - I've got an LS2 and it's remarkably small within the engine bay given the capacity.

I really don't know why they've not been an prevalent in diesels though, given the low-down torque general characteristics of pushrod designs.

I am aware of that. It’s also the butt of many jokes about lack of innovation within that that particular company. It’s also not a diesel.

And I'm clearly a little biased given my own, but much I'd rather have something like an LT2 over a modern turbo'd 4 or 6-cyl with all the complexity. I'm hanging onto my old school engine as long as I can.

Im of similar opinion but that doesn't make it good in the modern world for a variety of reasons.

Certainly wouldn't warrent designing a slew of new pushrod engines.

General Motors in the U.S. still uses pushrod 2V OHV in their V8 petrol and diesel engines. American style V8s generally have large cylinder bores and shorter strokes, so you can still get a large valve area with 2 valves. The cylinder heads are simpler to cast and the parts count is lower. You only need 1 camshaft instead of 4, 16 valves instead of 32, etc. A single cam with 16 valves has lower friction than four cams with 32 valves, so that helps fuel economy. DOHC 4V isn't automatically better for every application.

so that helps fuel economy

Tenuous link when for most of the other reasons you've outlined why they work for American v8s that a given massive displacement the bhp and the fuel economy is frighteningly low. That's another reason we have moved on from it here in the UK.

And I’m clearly a little biased given my own, but much I’d rather have something like an LT2 over a modern turbo’d 4 or 6-cyl with all the complexity. I’m hanging onto my old school engine as long as I can.

What Trail Rat said. You might be nostalgic for mechanical simplicity but what you call simple I call crude.

What Trail Rat said. You might be nostalgic for mechanical simplicity but what you call simple I call crude.

Its all moot anyway - given the rise of the brushless electric motor and the level of simplicity that brings compared to any flavour of internal combustion engine.

I'm hoping to make excellent use of all the 'crude' sportcars that nobody else will want because they've been made obselete by electric motors over the next 10 years*

* probably wont happen , as all the other sportcar fans will have the same idea.

Ohv is only a real benefit in something like a larger V8 engine where ohc is going to make the engine taller and wider with more mass further away from the crank. Less cam drive train as you only need one cam at the bottom of the valley thus making it cheaper to produce. Or ease of maintenance on parts that could actually be redundant. Or cheap because the tooling is already paid for 30 plus years ago...

OHV engines tend to be large capacity engines so producing torque isn't really being compromised by what drives the valves.

Hey why not just use big diesel 2 strokes like they do in the marine vessels...

Isn't any other justification is a bit like saying my bikes suspension linkage is the best because it's on the bike I own and that's what I'm used to. Why don't we argue for the return of URT suspension as it's simplicity is far superior?

A guy that came to my workshop a couple of years ago wanting help to finish making a "revolutionary" supercharged, V twin, side valve, pushrod engine prototype that was in his eyes going to change the world. I had to try and tell him it wasn't something I would be comfortable to spend his money and put the time in to. That in the past 70 years there have been some fair advances in technology. And that it might be worth looking at the efficiency, power and service schedules that was available from the current generations of production engines that have had many thousands of hours of development over several generations.

Possibly also a factor that until relatively recently a diesel would have needed a long cambelt to drive a mechanical injector pump, so the advantages of keeping a short timing chain wouldn't apply. More recently people want quieter, higher revving, less "dieselly" engines.

so that helps fuel economy

Tenuous link when for most of the other reasons you’ve outlined why they work for American v8s that a given massive displacement the bhp and the fuel economy is frighteningly low. That’s another reason we have moved on from it here in the UK.

If you look at the Australian touring cars (i.e. V8 Supercars), they run Nascar based pushrod V8 engines for the GM and Ford teams. Nissan, Volvo, and Mercedes were also involved but withdrew, they used DOHC V8s. Because of the constraints in the regulations (7500 RPM limit, plus restrictions on valve lift and duration), the DOHC engines weren't any more powerful but the Nascar engines had better fuel economy.

The 1994 Indy 500 was won by a car with a pushrod engine, build buy Ilmor and funded by Mercedes-Benz.

The assumption that OHC is inherently better and pushrods are "crude" is too simplistic. It depends on the application, for some applications, OHC is an unnecessary complication.

300tdi engines are definitely pushrod engines. I’ve had the head off of mine

In the marine world only 4 stroke generators are running on pushrods, the large 2 strokes aren't even running camshafts any more and instead rely entirely on electronic timing and actuation. That's where the real savings are.

Double overhead valves mainly.

Push rods give good low end but lack at high end /lack revs also

That's just a function of the cam you put in it though? Before the 90's there were plenty of rev happy pushrod petrol engines. And it fairly moot on a turbo diesel too because they inherently don't rev.

Double overhead valves mainly.

Pushrods disappeared first though? And 4-valve pushrods been done.

But bringing it back specifically to turbo diesels, forced induction narrows the gap between 2-valve and 4-valve. On a NA engine you're trying to minimize pressure drops so every fraction of a psi gained by polishing the intake, higher lift cams, more valves etc is of benefit. A turbo is just throwing 15psi against it. It's why any old spotty teenager with a laptop can set themselves up as a diesel tuner.

Struggling to think of the benefit for general purposes.

It wasn't so much a question of benefit, more of a thought about why we changed?

Pushrods increase parts count, complexity,

No, it's definitely simpler. Especially to assemble and work on. Taking the head off a pushrod engine takes minutes.

Not sure how a pushrod is an improvement over a cam acting directly onto a hydraulic tappet then the valve.

Not saying it's better, but for a diesel where the power runs out at 3000 and the redlines 5000rpm, I'm not really seeing why we didn't go down the route of hydraulic tappets on pushrods.

If nothing else you lob 150mm off the height of the engine (aerodynamics, pedestrian safety etc).

The best argument I could think of was where you have petrol and diesel engines built from the same block so it's saving tooling.

for a diesel where the power runs out at 3000

That hasn't been the case for a long time.

If nothing else you lob 150mm off the height of the engine (aerodynamics, pedestrian safety etc).

Tell that to my pushrod diesel.

Tallest engine I've ever seen lb for lb

for a diesel where the power runs out at 3000

That hasn’t been the case for a long time.

Don't you have the 1.6 16v diesel in your Berlingo Tina's

but i would love to see a deisel elec hybrid

@singletrackmind, I'm pretty sure this is how the hybrid Ford Transit Custom works. It's bloody expensive too!!

Peugot had a diesel hybrid too. 3008 - not sure if there've been any more.

I've worked in Diesel engine design and development for the last 10+ years, including automotive and industrial size engines (1.6 - 78 litres) - currently working at the industrial end of things.

In short, side-cam / push rod engines have many disadvantages and only a few advantages, which means that they're only used on larger, industrial engines.

Disadvantages:

High mass of the whole pushrod/rocker system leading to valve dynamics issues, i.e. max rpm limitations. This leads to compromises on the cam profiles that can be used and also the weight of the valve becomes important, hence the design has to be compromised to keep weight down.

Higher cost & part count - all of those additional parts - the pushrods and larger, more complex rockers add parts cost, weight and assembly time (important for high volume manufacture)

Advantages:

The main one - cylinder heads can be removed without removing the camshaft. Industrial engines usually have individual cyl heads and can run through several sets of cylinder heads per every major engine rebuild so this is important. Car engines typically have one head for all cylinders on a bank and also have fit-for-life cyl heads so little need to be able to remove the head during normal service life. Note industrial engine can have a time to rebuild in the 20-80K hour range.

More durable gear rather than chain or belt drive for the camshafts is more straightforward. Important for life reasons. Also loadings are a lot high on industrial engines, especially with high cylinder counts - for example a 60L V16 has a lot of cam load.

TL:DR - For automotive engines pushrods are more expensive and impose limitations. Overhead cams are cheaper and have less limitations.

Don’t you have the 1.6 16v diesel in your Berlingo Tina’s

2.0, so it's a SOHC and no intercooler.

Hence my thoughts on why if they clearly weren't fussed about intake density or pressure drops, why did it need an OHC.

why did it need an OHC. why did it need an OHC.

As per my previous post - because it’s cheaper and both better performance plus easier to engineer a decent performance.

Why would they have designed a more expensive, lower performance, more expensive to develop engine ?

2.0, so it’s a SOHC and no intercooler.

Same block used in the 16v version in the b and c varients fitted to most things except the Berlingo is the likely answer for the tractor engine not being push rod.

TL:DR – For automotive engines pushrods are more expensive and impose limitations. Overhead cams are cheaper and have less limitations.

GM looked at all this with their V8s, but stuck with pushrods. They obviously decided that the cost/performance benefits for that application (large capacity V8) made pushrods competitive.

Variable valve timing would be cheaper on a single camshaft engine compared to DOHC on a vee, surely.

GM looked at all this with their V8s, but stuck with pushrods.

I think that's likely a combination of marketing (Good old fashioned all American V") and the cost of redesigning and retooling their base engine block.

Variable valve timing is usually done via either manipulating the belt runs, or via a variable cam pulley (the inner and outer can move relative to each other) - in the latter case you can manipulate the intake and exhaust timings independently on a DOHC engine, whereas with SOHC cam you only move them together, but of course is cheaper (one fancy cam pulley needed not two).

GM looked at all this with their V8s, but stuck with pushrods.

I think that’s likely a combination of marketing (Good old fashioned all American V”) and the cost of redesigning and retooling their base engine block.

This and a case of if they're selling like hot cakes then why change? Making product changes is horrendously expensive and very disruptive so you only change your product in response to competition or changes in regulation. Other factors also but mainly those two. With a whole industry of aftermarket parts out there it makes the engine very accessible for the DIY mechanic/hot rodder who might be their main customer base.

I think that’s likely a combination of marketing (Good old fashioned all American V”) and the cost of redesigning and retooling their base engine block.

They completely redesigned the Chevy small block back in the 90s, then again about 10 years ago. The new engines have the same general layout and bore spacing as the classic small block, but nothing else was carried over. They also had a different line of V8s used by Cadillac, with DOHC layout (plus the old DOHC V8 they used in the Lotus Corvette back in the 90s). They dropped the DOHC Cadillac engine in favour of the pushrod Chevy engine. The pushrod engine has variable valve timing and other modern technology, so the GM engineers clearly decided that a single cam OHV layout had advantages for a big V8. The performance versions are cranking out 450 to 500 BHP in stock spec, so the "crude" technology doesn't seem to be too big of a handicap.

Nascar engines crank out 800 HP and rev to 8500 to 9000 RPM, so pushrod 2V engines aren't as terrible as people imagine.

The performance versions are cranking out 450 to 500 BHP in stock spec, so the “crude” technology doesn’t seem to be too big of a handicap.

Nascar engines crank out 800 HP and rev to 8500 to 9000 RPM, so pushrod 2V engines aren’t as terrible as people imagine.

Both attributes 95% of the car driving population need in spades. How are the economy and emissions compared to a non 2v non V8 option.

Both attributes 95% of the car driving population need in spades. How are the economy and emissions compared to a non 2v V8 option.

Comparable/better than other (less 'crude' ) engines of similar power/usage/category it would appear

https://www.motortrend.com/news/c8-corvette-official-fuel-economy-mpg/

Both attributes 95% of the car driving population need in spades.

Nobody needs that. The point is that pushrod 2V engines can perform pretty well. Any car sold in the U.S. has to meet emission and fuel economy standards. GM obviously factored that into their decision to stick with pushrod engines. TBH, I was surprised when they stuck with pushrods, but their V8s do seem to perform well.

I’m not sure I understand the question. The 300tdi does indeed use pushrods to operate the valve train, but the camshaft is belt driven, so you still need to change the belt and tensioner bits.

GM looked at all this with their V8s, but stuck with pushrods. They obviously decided that the cost/performance benefits for that application (large capacity V8) made pushrods competitive.

Just because a US manufacturer makes something for the US market don't assume it's any good. In my experience US cars are generally pretty shit in engineering terms, but most people don't care as long as they go and look good. Driving dynamics aren't really a thing there. Manufacturers only want to sell new cars cheaply and they really don't care about anything else. That's why there's so much garbage on the market but as long as it has enough toys and it's cheap, it sells.

The point is that pushrod 2V engines can perform pretty well. Any car sold in the U.S. has to meet emission and fuel economy standards.

Do they perform better than the belt driven equivalent?

And what are the fuel economy standards? The emissions standards that I am aware of are mostly concerned with NOx which is how you end up with large displacements and low specific power (or you used to).

Just because a US manufacturer makes something for the US market don’t assume it’s any good. In my experience US cars are generally pretty shit in engineering terms, but most people don’t care as long as they go and look good. Driving dynamics aren’t really a thing there. Manufacturers only want to sell new cars cheaply and they really don’t care about anything else. That’s why there’s so much garbage on the market but as long as it has enough toys and it’s cheap, it sells.

yeah, the new corvette c8 with the 'crude' pushrod v8 is rubbish.....

https://www.topgear.com/car-reviews/chevrolet/corvette-stingray

I see suspect (and I'm happy to be proven wrong) that if you added all the cars in that motortrend post together they would account for less than 1% of all cars in the UK. Making it not relevent to much.

We are a nation with high fuel prices and rightly or wrongly high urban density motoring. -very few open highways

We need pushrod v8s like a hole in the head. And further we still have not found out why a new push rod diesel would be an improvement over dohc diesels

yeah, the new corvette c8 with the ‘crude’ pushrod v8 is rubbish…..

Does it come with a GPS automatic limiter and driver facing cameras ? That would make it better.

I suspect (and I’m happy to be proven wrong) that if you added all the cars in that motortrend post together they would account for less than 1% of all cars in the UK. Making it not relevent to much.

I didnt say anything about sales volumes, you asked how the 'crude' pushrod v8 compares in terms of fuel economy to its more sophisticated peers, and the answer seems to be 'quite favourably'.

Dont get me wrong , I have no dog in this fight, but to just dismiss that particular pushrod v8 as crude, low performance, poor fuel efficiency or any other stereotype that used to be laid at the door of the 70's pushrod v8's seems to be laazy stereotyping to me.

I'm not sure GM's use of rods to waggle the valves counts much of either way in engineering terms here. It worked for them on that engine in that market.

Well I did actually mean non 2v non V8...as per the almost immediate edit.

As in normal cars.

And for completeness. Nothing mentioned of emissions either just economy.

As you say it's not 1970any more that sort of info is important today.

This is an interesting read on pushrod engines in new motorbikes - concentrates on the new BMW cruiser but lots of tech info too https://www.bennetts.co.uk/bikesocial/news-and-views/features/bikes/air-cooling-and-pushrods-bright-future-for-old-tech

We need pushrod v8s like a hole in the head.

Oh I agree, but same could be said for any high-performance engine. Just so happens there's something deemed even more anti-social about a large capacity V8 compared to smaller engines that provide similar power/economy. But it lets me live out my Days of Thunder / Mad Max fantasies...

On economy, relative to the performance a pushrod V8 petrol isn't all that bad (all for similar driving under my heavy right foot, much with bikes on the roof):

330i 6-cyl 260ps, 24mpg

MINI Cooper S 1.6 4cyl 185ps, 32mpg

6.0 LS2 V8 400ps, 20.5mpg

Push rods give good low end but lack at high end /lack revs also

Why would a push rod engine give better low end? you could have any cam profile you could have with a push rod engine in an over head cam engine. I would agree you might not be able to rev a pushrod engine as high as an OHC engine without some very expensive parts and mitigation's. but I can't see why a push rod engine would have more bottom end by being a push rod engine.

the answer seems to be ‘quite favourably’.

Far far more data is needed to make a call about the relative merits of these particular engineering solutions. If only we had someone well qualified to make call. Oh wait we do, and you ignored them.

Just because Top Gear like a car overall, doesn't mean the valve actuation mechanism is empirically better than the other solution. Car might've been even better if it had DOHC.

Dont get me wrong , I have no dog in this fight, but to just dismiss that particular pushrod v8 as crude, low performance, poor fuel efficiency or any other stereotype that used to be laid at the door of the 70’s pushrod v8’s seems to be laazy stereotyping to me.

This is exactly the point. Just dismissing pushrods as "crude" is silly. Obviously, DOHC has become the standard layout because it works better for most applications, but pushrod engines aren't as agricultural as you might assume.

If you're interested, I drive a Toyota with a 1500 cc DOHC petrol engine. I am astonished at how well it performs for a cheap shopping car, plus how little fuel it uses.

Why would a push rod engine give better low end?

I think that's inherently associated with 2-valve heads rather than pushrods. You have good swirl from the larger valves but you can't do much timing overlap as you can with 4 valve. That leans toward lower rpm operation. Any power difference could be fixed with a bit more displacement.

4 valves on pushrods has been done. Not sure its the 'simple' route to making 4 valve heads work. Hasn't been done much AFAIK.

My 2v pushrod 80hp Guzzi is good for 45mpg even in 'not particularly hanging about' mode - much better than the DOHC 4v 90hp triple in the Triumph which struggles to 40mpg unless ridden in a nun-like fashion.

The Guzzi engine is a damn site cheaper and easier to service too - no water cooling, less valve clearances to check, no cam-chain or tensioners to check/replace

Thanks, interesting article

That GM piece is interesting - I wasn't aware of this and it's counter-intuitive, but as all designs are compromises it looks like this compromise worked for GM in this market.

A very quick skim read of the literature suggests that the package size part of this is a big deal which makes sense for large automotive V8s, hence power density in terms of bhp/kg is high.

It's impressive that they have got reasonable efficiency and I assume have passed emissions regs with this. It looks like they're supercharged and direct injection which will help.

I'll be taking a read around this this evening.

https://www.holley.com/blog/post/everything_you_want_to_know_about_the_gm_gen_v_lt_engine/

Do bear in mind that this is a specific market, and GM are using OHC for their smaller engines. I highly doubt that this is economically transferrable to smaller engines such as those used in the UK.

pushrod engines aren’t as agricultural as you might assume.

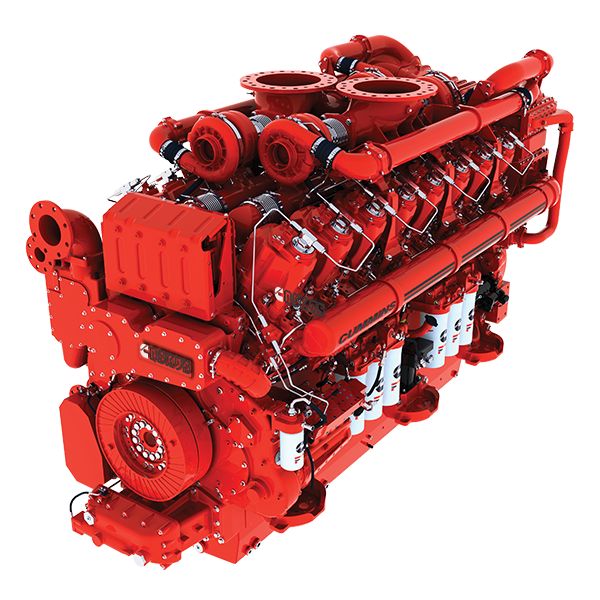

True that. This is what we make at my work. This one is a 95 Litre 5,000+BHP V16. Pushrod of couse.

Push rods give good low end but lack at high end /lack revs also

Ultimately, an OHC will rev higher because the valve gear is lighter and more rigid, so you can run more aggressive cam profiles. Performance engines have run DOHC for a century for exactly that reason. That doesn't mean that you can't make an OHC engine that gives good low end torque. If you run the same cam profiles, valve sizes, etc. you'll get exactly the same torque curve out of a pushrod and OHC engine. Nascar V8s are built to run at high revs and full throttle for hours on superspeedway, but they change cams for better low end torque on road courses. Nothing to do with with pushrods versus OHC, just the cam profiles you can run.

And further we still have not found out why a new push rod diesel would be an improvement over dohc diesels

I wasn't saying it was significantly better, or even that it would pass Euro5/6/7. Just on an "if it's not broke, why fix it" basis, why was it dropped? Long before DOHC's might have made it complicated, and long before the idea of a sporty diesel was thought up (and pushrod petrols are still 'sportier').

The only argument that really rings true is the one around using common castings for petrol and diesel engines. Rover did it with the pushrod B series, which became the O series then the T series, but they didn't convert it to diesel until the O became the L by which point it had already gained an OHC.

And I suppose prior to that there was no real interest in diesel cars? The exception that proves the rule being Landrover (not a car and used pushrods in a Diesel).

sure if you throw enough money at something you can make it do what ever you want it to do... It neither makes it the best option nor the right option.

For the majority of folks needs a push rod anything is not the answer

As for cam profile you can't profile your way out of a lack of revs - although we have 9 speed gearboxes these days to counter that to a point

In the same way you can't profile your self out of a lack of displacement (although you can charge your way through it to an extent)

“if it’s not broke, why fix it” basis, why was it dropped?

That is really easy to answer. See my first post for the main points. But... specifically relating to the valves and cams it goes like this.

For maximum efficiency and optimum emissions you want the valves to open as close to instantaneously as possible. When they open and close slowly they can't hit the "optimum" position for breathing and maximizing the work extracted from the combustion gases on the power stroke as the event is "spread out".

To get as close as possible to "instantaneous" opening and closing you need to open and close the valves quickly which involved accelerating the valve at a higher speeds.

Higher opening speeds mean higher stresses in the valvetrain system (valve stem, tip, the valvertrain itself including pushrods if any and the cam lobe, including all interfaces in this arranegemnt.). THere is a finite limit as to how high these stresses can be before you encounter issues - fatigue, surface wear, galling, breakdown of the lubricating oil film etc. The higher the mass of the system the higher these forces are for a given opening acceleration and speed, hence you need to either limit speed (RPM) or ramp rate, i.e. a slow opening valve (bad for efficiency and economy)

Higher closing speeds need higher acceleration to accelerate the valve fast enough to close on time and to avoid valve "float". This limits the maximum speed of the engine and also demands a stronger valvespring. Stronger valve springs increase the loadings described above for the opening loads, hence there is a limit. Pushrod engines have a higher mass in the system so these limits come into play earlier, meaning either lower max speeds or a slower closing rate is needed, hence bad for efficiency and economy.

The above factors mean that pushrod engine are more limited and are harder to engineer to achieve performance and efficiency. It's possible to engineer around these limitations, but why make it harder?

TL:DR - pushrods really are "old tech" for automotive size engines and whilst you can engineer them to work they have inherent limitations which have seen them superseded in the vast majority of cases.

The only argument that really rings true is the one around using common castings for petrol and diesel engines.

I'm sorry this is not the case. The benefits of OHC are clear for everyday automotive and it's hard to develop a competitive engine that meets emission standards with using it, which is why virtually all modern engines use it.

The above factors mean that pushrod engine are more limited and are harder to engineer to achieve performance and efficiency. It’s possible to engineer around these limitations, but why make it harder?

TL:DR – pushrods really are “old tech” for automotive size engines and whilst you can engineer them to work they hav

With vee engines, the valvetrain is much less complex with a single camshaft and pushrods. You can use a single gear drive to drive the camshaft. With DOHC, you need a much more complex system to drive two camshafts per cylinder bank. Most engines run DOHC, but that doesn't mean it's the best thing for every engine.

4 valves on pushrods has been done. Not sure its the ‘simple’ route to making 4 valve heads work. Hasn’t been done much AFAIK.

This is very common on larger industrial engines. The rocker gear is more complex as one pushrod has to operate two valves.

True, the cam drive arrangement can be simpler with a pushrod Vee.

The trade-off though is the valvetrain dynamics compromise which is generally more important.

Nascar engines crank out 800 HP and rev to 8500 to 9000 RPM, so pushrod 2V engines aren’t as terrible as people imagine.

Well yes but that doesn't help the case for pushrods though. The only reason they still have pushrods are because they have to. They also have to have carburettors too. Much in the same way F1 cars are limited to 13" wheels with high profile tyres. It doesn't mean or prove they are the best solution. Just because you CAN make these things chuck out good performance doesn't mean they are the optimal or best solution. If the restrictions were removed the pushrods, carburettors and low profile tyres would disappear overnight. They're just doing the best they can with what they're allowed to run. Also NASCAR engines sit at constant revs for basically all their time chucking out constant power so the inertia of moving parts due to changes in engine revs is not such an important aspect so they can really be optimised and tuned for a very narrow band of revs and power outputs. the benefit of variable valve timing and all the other tech in modern engines is to deliver optimal efficiency across the whole rev range.

Anyway cams are so old fashioned. The future is camless and pneumatically actuated. Actually simpler than cams. A chap on YouTube converted his MX5 to carless in his garage. Imagine him trying to manufacture his own OHV variable timing and lift cylinder head!

Guessing they wanted the bonnet on that Stingray to be low, and they still wanted a V8.

they still wanted a V8.

You only have to look at the hatred for the ecoboost Mustang to understand how important nostalgia is int he American market.

Guessing they wanted the bonnet on that Stingray to be low, and they still wanted a V8.

Current corvette is not front engined, it is the first mid engined corvette.

Looks nice, and priced well.

Oh yeah it even says that in the article. Still, could be packaging related just the same.

The future is camless and pneumatically actuated.

Why pneumatic specifically? Is it a speed thing? I'm just thinking back to marine engines, they were hydraulic on an air spring but only ran at 104rpm.

I thought the Fiat one (twin air?) was electronic rather than pneumatic. This is the only alternative valve technology I heard about.

The higher the mass of the system the higher these forces are for a given opening acceleration and speed, hence you need to either limit speed (RPM) or ramp rate, i.e. a slow opening valve (bad for efficiency and economy)

<pedant alert>Speed doesn't come into it, F=ma.</pedant alert>

🙂

Pedantry aside, are there any decent YouTube (or whatever) channels that explain the trade offs involved in this kind of thing?

<pedant alert>Speed doesn’t come into it, F=ma.</pedant alert>

Shirley a is governed by RPM.

More rpm means more reciprocations between open and closed. And to do more it has to me accelerated and decelerated quicker to fit more cycles in.

Infact speed is the only parameter the designer fully has control over everything else in that system is nigh on a closed loop derived from the other factors the system must also address at the same time.

M<pedant alert>Speed doesn’t come into it, F=ma.</pedant alert>

Speed is everything to do with it.

Force = mass x acceleration

Acceleration = speed / time

Re YouTube etc. If you google valvetrain dynamics you’ll find some stuff.

There’s the hobbyist / entertainment type stuff which is simplified, and the academic which is what you’ll need for a better grasp, but is rather dry.

One of the challenges with this type of engineering is that whilst each individual aspect is pretty simple the trade-offs and interactions involve multiple systems and factors which you have to understand to a certain level.

If you take as a starting point that the ideal airflow behaviour of a valve is to both fully open and close instantly, but also has to be durable it’s not a bad place to start.

As a really basic analogy to human scale interactions, imagine opening and closing a normal household door. Do it at “normal” speed. Nice and easy right? Now do it repetitively very fast for 2 minutes. Hard work right? Now do the same on a really heavy ok door. If you can achieve the same speed then it will be a massive amount harder. That very roughly analogous to a heavy or lightweight valvetrain.

The Fiat one, by the way, doesn't have a throttle - it controls the air mass intake by early closing the inlet valve. Pretty damn cool.

If you've ever driven a Sierra 2.3 diesel you'll realise why there's very few pushrod diesel engines around.

Our Xtrail accellerates faster with the caravan on the back than my Sierra did without.

There’s the hobbyist / entertainment type stuff which is simplified, and the academic which is what you’ll need for a better grasp, but is rather dry.

I've got a degree in Aeronautical Engineering, I'll survive.

Speed is everything to do with it.

Force = mass x acceleration

Acceleration = speed / time

That's splitting hairs. Once up to speed the force is zero.

As a really basic analogy to human scale interactions, imagine opening and closing a normal household door. Do it at “normal” speed. Nice and easy right? Now do it repetitively very fast for 2 minutes. Hard work right? Now do the same on a really heavy ok door. If you can achieve the same speed then it will be a massive amount harder. That very roughly analogous to a heavy or lightweight valvetrain.

So you're saying mass has a direct influence on the force needed for a given accelaration?