![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

I need two stainless steel sill protectors for my little tarty car now that I have had it painted pretty.

I think I want them about 0.5mm - 1mm thick and probably brushed finish rather than shiny so the scratched are less obvious. I have made the cardboard template below.

Anyone got any idea where I can get the metal and then get it cut to size or is it reasonably easy to cut them out myself with a disc cutter in which case I just need to know where to get the sheet.

Suggestions please?

If you can draw it in CAD then you can get it laser cut and delivered. There's a few places that do it. It'll be an easy shape to draw even if you've never done it before.

Agree with nickjb that laser cutting is the easy way if you can get a CAD file. If you cut it yourself, I get sheet metal from metals4U, eg

Brushed Polished Stainless Steel Kick Plate 0.9mm 304 | metals4U

Good link Richmars - thanks

Now can I get a diamond disc for my circular saw?

Is the sill still from the donor car? Bet there are loads of those readily available. How about clear paint protection film. That you can easily DIY.

i'll draw that up for you if you want.

What do LAsers cutters generally need, DXF? DWG?

DXF usually. Put some rounded corners on it whilst you are at it 🙂

Seriously - ready profiled parts (laser, water hi-def plasma etc) aren't expensive. I'd just Google local profile cutters and get to know them for your many future projects.

Don't forget stainless is pretty stiff, so if that's a perfectly flat profile then it won't matter but if you need to bend/flex it at all I'd go as thin as possible.

This is the sill area and I need something to cover the bolt holes. M<y plan is to use some 3M number plate tape to fix the plate to it.

Here is a gratuitous picture of the car now it is red.

I shall be looking for local laser cutters and seeing how thin they can go. Ideally it will match the thickness of the steel sheet it butts up against.

Looking at the stock BMW part is looks to go slightly up the rear of the door frame and covers some ugly bits there.

Is that a z3 with some DBR esque front end?

If it is, is there not an OEM part to cover that? Surely the doors aren't changed? As above, any profile changes and that will lift and/or look a bit crap. An OEM part would be significantly less hassle.

Edit: like this

It is a BMW Z3 but the stock parts and aftermarket things don't look great. I want something plain and simple rather than made from plastic and chrome. If I can get thin steel sheet then I have a special profiling hammer and lump of wood to deal with small changes but the sruface is pretty much flat anyway

Aalco for metal in Southampton.

Fabrication guys i used to use were down Thomas Lewis way.

Or another lot down the bottom of tje hill in Winnall were also good.

Will have a think and see if i can remember the names

I use Premier laser in Corby for prototypes and they are excellent and will deliver in days. You will need a DXF file though.

Okay - it looks like I need:

1) Properly measured dimensions.

2) Someone to turn those into a DXF file.

3) Some sheet stainless steel - Metal supermarket seem cheap and easy for either 0.7 or 0.9mm base don online quote

Dull Polished 0.9MM STAINLESS STEEL 430 SHEET 1400mm x 850mm Qty 2 = £16.70

4) Find a laser cutter / fabricator to cut to size (SingletrackMind - if you find the name, thanks)

And all will be well.

I've never ever had to supply my own material unless something oddball like water jet big bits of 3" thick aluminium - have you spoken to some profile cutters to see what they have?

As a last resort I can do the DXF but probably easier for others. Let me know if no luck in a day or two.

If you get it laser cut you won't need the material. They'll use their own stock. Cost per part is usually not much more than material cost. There might be a minimum charge, set up charge, plus delivery charge on top though

Thanks, I will talk to the cutters first and explain what I want. Hopefully they will have somethign suitable.

I've used Alden in Southampton for buying small amounts of sheet metal before. They are a fabricator that mostly do larger stuff, but sell the offcuts cheap, so I'm sure if you went in with the dimensions, they would be able to sort you out

I've used a little company in Salisbury called Lasercell a number of times before. I'm sure they could hook you up quite easily too.

I think I want them about 0.5mm – 1mm

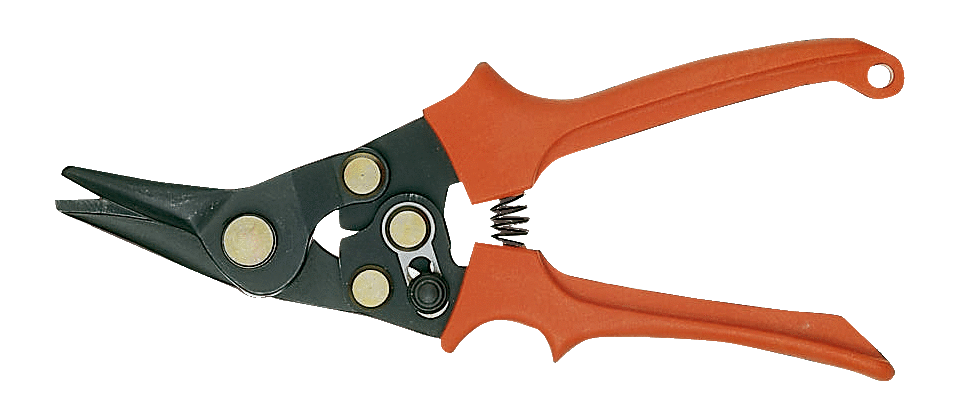

For something that thin, could you not use a paper template and aviation shears then files?

Do they cut stainless well?

I've used them for 1mm bodywork mild steel which is easy to cut I guess.

Could you use ally and do it on your bandsaw?

Metal cutting blade on the bandsaw and stainless?

Cnc seems to be more complicated than it needs to be?

Would be very nicely done though of course.

Aviation shears won't be nice on stainless, its too hard and you'll never get it flat again after when you inevitably bend the edge.

Bandsaw probably won't go slow enough for stainless.

Personaly without the right tools just get it laser cut. If you want to DIY get the main rectangle cut to size by the material supplier. Then for the internal angle cutout use a 4 1/2" angle grinder with 1mm inox cutting discs going steady not to dig in but not letting it rub and burn. clamp between 2 bits of wood to support the sheet and act as a fence if you like. Then finish it of with a fine grit flap disc and a rotary flap wheel or scotchbrite wheel depending on surface finish.

I have DIY cut steel before so will be using a professional to keep this looking pretty for the tarty car

Lasercell do a good job, we use them occasionally. They're in West Dean between Romsey and Salisbury.

If you've got a dxf file, that makes it easy as they just cut to that. Otherwise speak to them (Tom's pretty helpful) and they'll sort the profile out for you.

They can bend as well if that's useful.

Ended up ordering 2 pieces from Metal Supermarket for £12 and will cut/grind/polish the end notch myself.

Photos on the What have you Made thread in a while if it works

Not too bad for my own cutting. The slightly raw edges on the cut out rectangle are mostly hidden behind the panel anyway.