![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

I'm in need of 60cm of delrin channel for a piece of hardware that's US made.

The company sell it as a spare part but it's $35 plus $85 shipping - I'm hoping I can do better than that!

Any suggestions as I'm a bit stuck 😩

(Dimensions are 12mm wide, 20mm high with a wall thickness of about 1.5mm when viewed as a cross section U)

Edit: or is anyone able to bring some back to the UK from the US?!!!

It’s generally referred to as acetal or POM in the UK if that helps.

Does it have to be acetal? Much easier to find something like that in aluminium

Get a local machinist to make you some out of solid?

It’s generally referred to as acetal or POM in the UK if that helps.

Yes it does thanks 👍

Does it have to be acetal? Much easier to find something like that in aluminium

Yeah, it's actually to allow an aluminium plate to slide within and aluminium channel

Get a local machinist to make you some out of solid?

I'll look into that but it may be more expensive than just buying it from the US!

Could you use three separate bits of 1.5mm sheet cut to size?

edit, or use a bit of heat to form a sheet into a U shape?

Make it yourself from a piece of suitable solid 12 x 20 section.

- Buy a woodwork router from Screwfix. Probably one for a 1/4 shank tool bit.

- Choose a router bit for a 9mm cut (Your 12 - 1.5 side - 1.5 side=9)

- Clamp up securely.

- Take a number of light cuts and remove 18.5mm (Your 20 - 1.5)

- Keep the router for another job.

I've been tidying the workshop and I have a rack of random plastic. I noticed I have some U section 25x14mm 1mm wall (14mm is the bottom of the U). Unknown black plastic, probably PVC or polyethylene. You can a have a bit for postage if it works for you (or collect from Bristol if you are nearby). It'll be easy to trim the 25mm dimension down but the 14mm is what it is although it will flex a bit.

That's super-kind but the application doesn't really allow for much in the way of bodging - there's nearly 300kg bolted to the plate that runs within the channel so I think I need to bite the bullet and order the proper stuff!

Thanks again though.

Some sailing fittings may work? Traveller channel or similar?

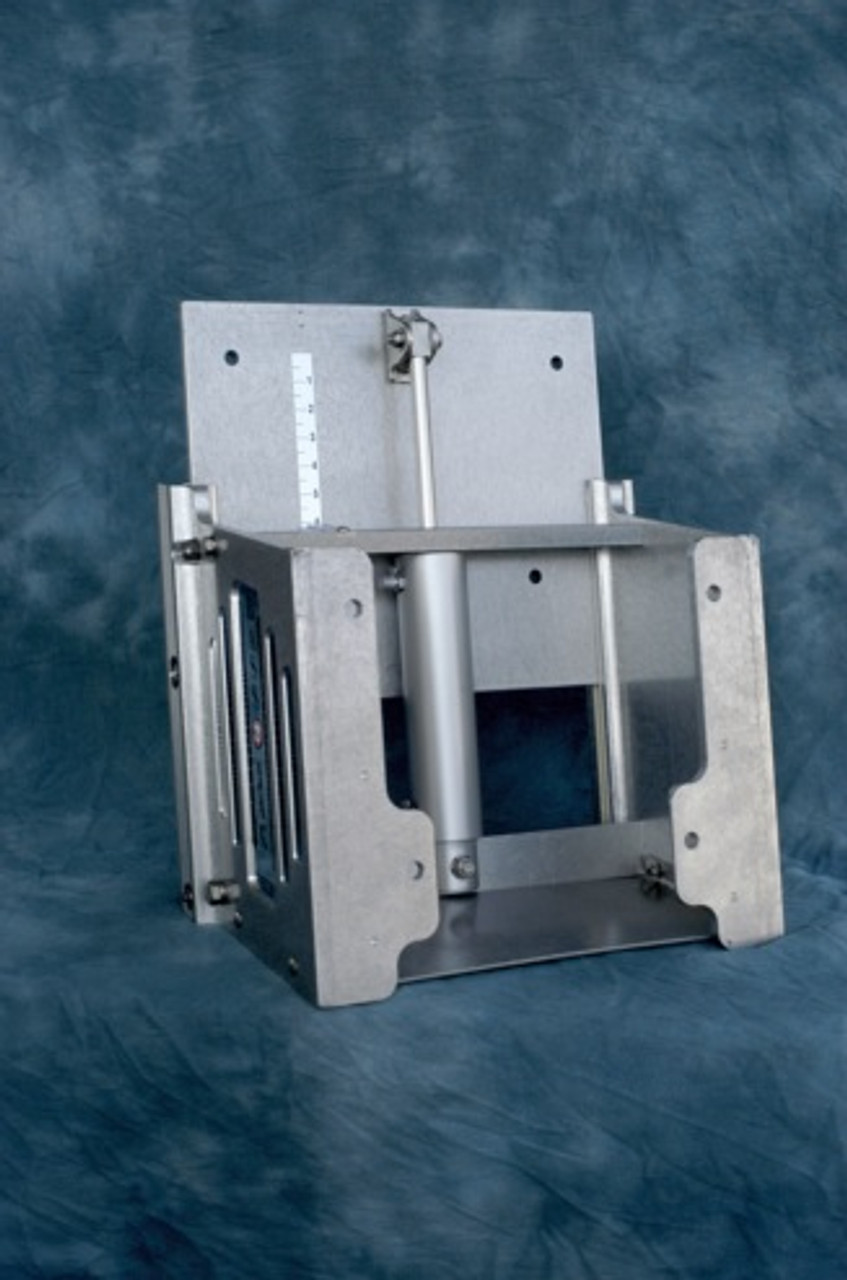

It's actually for a jack plate that hydraulically adjusts the height of an outboard engine:

Do you have a drawing of the channel? Is it square bottomed?

I'd buy some Delrin sheet from Ebay, cut and file / sand to exact size then use a router in a table to machine out the channel. If you don't have a router table it's easy to make a simple one from MDF and pine offcuts. Or for this application you could build a one off jig out of MDF or plywood.

It’s actually for a jack plate that hydraulically adjusts the height of an outboard engine:

Could you also change the runner then?

Because things like this are plentiful:

Could you also change the runner then?

Not really possible TBH (I sail a lot and had briefly thought of this and would rather keep it stock).

Do you have a drawing of the channel? Is it square bottomed?

I'm starting to warm to this idea slowly. It is square bottomed so it's really just a 1.5mm thick walled channel. I don't mid having a go at making stuff but would need to buy a router as well so probably not exactly cost effective!

(Not that anything to do with boats is ever really cost effective!)

If you've got a table saw or a track saw you could cut the channel with that. If you need to buy a router the Katsu palm router is good (and cheap), it's a clone of a Makita

I have a track saw but I'm not sure I'd trust myself to cut to a 1mm tolerance!

At <£200 for a boat component I'd just buy it rather than loosing a finger from bodging a router to 'machine' it.