![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

So we're going up with the kitchen roof this week and we are doing it all ourselves - at the moment we're just doing a like for like replacement - its a big open plan 50m2 room with just the single floor.

We've got the wood for the a-frames and we're using nail plates to join them together and then thinking of using big metal plates with coach bolts either side to hold it all snugly together (each end of the triangle and in the centre)...

has anyone done similar as I'm struggling to find many plate examples on the net before I go to a metal fab

Thanks

I wouldn't go to a metal fabricator. I would try and find a local laser cutting company if they are just flat plates with holes in.

Most have an in-house design service who could translate your sketch or even better if you can produce a cad file (.dwg, .dxf etc.) they can work directly from it. Accuracy is very high and prices are very reasonable in my experience.

If the the plates are simple send me a sketch and ill draw them up and send you back the correct cad file to give the laser company.

andysredmini at hotmail dot com

Spot on Andy, thanks very much for the offer - thats exactly what we want the plates will be super simple - i was even tempted to have a go at grinding them myself and just spending a few hours sanding

looks like we could be in luck with a local spot!

http://www.norwestengineering.co.uk/laser_cutting.php

I wont know the designs until we've tac'd the frames together but I'll give you a shout if we get stuck

Thanks

Just email me pics of the sketches and ill draw them up for you.

I do it as part of my job and am lucky that I can get what I want made and loose it in a job. Trouble is you soon run out of cool things to make.

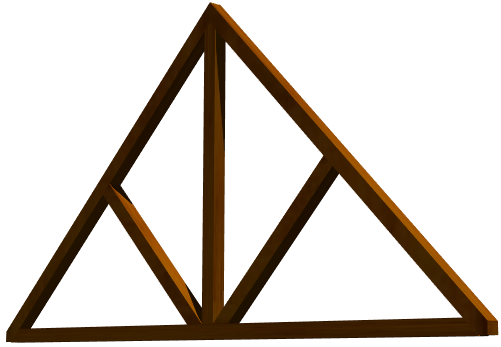

Hi Stoner, the rooms 6meters wide and because we're doing like for like (trying to get the roof on before planning as it's falling down and winters en route).. it's this design:

We are going to use those metal fixings to get it together but we are doing no jointing just butting the wood together as theres only 2 of us and we're pretty tight on time - thats why I was hoping the plates will give us some good strength and a bit of a feature in the kitchen

(I was hoping to leave the 2 diagonal pieces inside the frame just held at the top with those nail boards as they should be strong enough i'd have thought and you won't be seeing the top behind all the insulation / plasterboard.)

You could if budget allows get them done in stainless and get them brushed or polished. Alternatively get them galvanised and leave them unfinished which can give a industrial look.

Cheapest would be probably be powder coating.

I think we're going white or light with the beams as they are the nasty yellowish treated colour (nothing special) so probably going to go with a stronger look so we were thinking a black powdercoat

I quite like the idea of polished stainless however but the misses is running the show!

May be worth asking how much they would be in stainless. Might not be much different than mild steel plus powder coating.

I don't get much stainless cut so I cant offer any advice on pricing.

You can brush them yourself with a belt sander or you can use any orbital sander (or by hand) to give them a dull polish.

You should be able to get almost any kind of builders metalwork off the shelf.

of coarse you could get exactly what you want made up, but it would take longer and cost more

[url= http://www.expamet.co.uk/webfm_send/189 ]Builders metalwork[/url]

even a trawl around the usual DIY sheds websites you would prabably find something suitable.

Thats it yep! tempted to go full beam width though possibly but yes those exact things 🙂

ps - just done a search for "joining plates" and can't see anything that large out the box - am I using the wrong terminology?

Also any idea's on what kind of mm I should be looking for in thickness I guess as there are no joint's they are taking most of the load so probably looking around 3/4mm?

[url= http://www.vermonttimberworks.com/learn/timber-frame-joinery/steel-connections/ ]Probably the best examples so far..[/url]

this kinda stuff - all american based though!

In that case OP, make a truss and then use that for making up templates c/w bolt holes, to give to a local fabricator. Then get them powder coated for good measure and you'll get what you want 😀

Those ones in the pics will be easy to do. I always overbuild everything so would probably use 5 or 6mm