![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

I bought a 'cheap' Chinese lathe to keep myself entertained during lockdown, and then started doodling with CAD (Fusion 360).

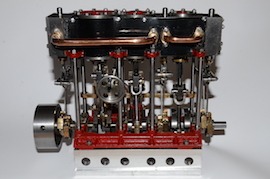

This is what came out:

Stats:

Bore: 20.4 mm / 0.8"

Stroke: 26 mm / 1.02"

Displacement: 8.5 cc

Compression ratio 4:1

The flywheels are cast iron trolley jack wheels.

I anodised all of the aluminium parts using the process described by Mark Presling on Youtube

It even runs!

(I'm using Coleman fuel with a few percent marine two stroke oil to try and keep the valves and top-end lubricated.)

VERY pleased with the way it has turned out! 🙂

Very nice

Excellent work! Would you share the details of the lathe please?

That’s amazing. Nice work.

Excellent work! Would you share the details of the lathe please?

Id second that!

Oh I say. That's lovely.

Thanks! 🙂 🙂

Would you share the details of the lathe please?

It's a generic Chinese 7 x 14 lathe - I think it's a Seig SC3 with the brushless motor. Similar to this:

https://www.amadeal.co.uk/acatalog/CJ0618A-350-BRUSHELSS-Motor-Mini-lathe-AMA_LA_CJ18ABRB.html#SID=2

but variations on the same theme are available from a number of suppliers (e.g. Arc Euro, Chester, Amadeal, Warco...)

https://singletrackmag.com/forum/topic/new-toy-to-relieve-the-lockdown-tedium/

Stunning. Very nice work.

Colour me impressed

Love the unpredictable rhythmic noises these machines make. Never knew they were called hit & miss engines, makes sense. Love looking/listening to them at steam fairs too.

Shame about the car engine noise in the video. It was my idea of good ASMR until that point!

That is nice. Blinking heck there are some very talented people on this forum.

Some people have too much time on their hands and lots of skills going spare..

Very impressed.

Very nice work!

What did you use to radius the con rod? Did you cut the brass gearing yourself?

Turned round then milled flat?

That is absolutely ace.

Soon to be seen at a country fair annoying the poor souls who happen to have a nearby stall. You'll need a deck chair and a small rusty campervan and your summer will be sorted.

Very impressive pointlessness.

Just awesome. Love it!

Absolutely amazing 👏

So you bought a spinny round very fast thing and used it to make a spinny round very fast other thing. Good work OP, looks and sounds nice.

Excellent work there!

Soon to be seen at a country fair annoying the poor souls who happen to have a nearby stall. You’ll need a deck chair and a small rusty campervan and your summer will be sorted.

Very impressive pointlessness.

I was thinking exactly that! It’s a really lovely thing, it’s beautifully made, and I love it to bits! Congratulations. 👏🏻😁

That looks absolutely brilliant. Even if it wasn't a working engine it'd be amazing.

Meanwhile I've been on instagram.

Thank you all for the kind comments - well chuffed!

Shame about the car engine noise in the video. It was my idea of good ASMR until that point!

Thanks! 😀 If you listen carefully, you'll also hear my wife arriving home with the dogs and asking if I'm trying to make a quiet video...

What did you use to radius the con rod? Did you cut the brass gearing yourself?

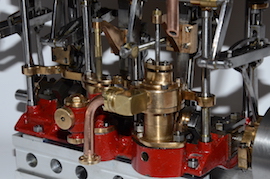

The conrod was turned from a flat piece of aluminium which gives the radiused edge (I don't have a mill, it was all done on the lathe or by hand). I bought a couple of standard brass gears and modified them to suit.

Is anyone else slightly upset with the use of allen heads?

Whitworth would have been more appropriate surely.

Oh! Just had a thought, you could use it to drive a lathe to make another one, a sort of engineering fractal as it were.

Ha! Wonderful nonsense. Well done op

Whitworth would have been more appropriate surely.

LOL! Don't imagine I didn't consider it!

use it to drive a lathe to make another one

Haha! That's now top of the list of suggested uses (previous was for powering a pencil sharpener).

Thanks! 🙂

Even by STW standards, that's amazing op.👍

I might have managed to turn a door knob or something then given in.lol

Well then ,I am even more impressed.

Excellent effort.

That's bloody fantastic. Mostly what I make with my little lathe is flesh wounds.

cool, really like that, well done

Very impressive. Pointless, but no less impressive for that.

Stunning! No more to be said...

Given time, tools, inclination, and a few discards, I could have just about made that.

(the piece of wood it's mounted on)

The engine - stunning, love it.

More worrying, someone said ASMR which I didn't recognise, so I googled it. I've now just spent nearly 20 minutes while a lady whispers to me about her glasses collection.

[Takes a bow]

Thank you very much indeed! 🙂

Superb, i love it!

Lovely job 🙂

Was going through some of my dad's stuff earlier and turned out the unmachined kit of parts that turns into one of these:

I've been thinking about getting a lathe 😉

Good job. Love stuff like this.

Was going through some of my dad’s stuff earlier and turned out the unmachined kit of parts that turns into one of these:

Stuarts Triple Steam Engine

Ye gods! You'll have your work cut out with that. I guess you'd need a mill (or a strong filing arm) too.

I've never machined anything from castings, but it looks like a new level of challenge because you don't have any datums until you start machining. For an idea of what's involved, I find this guy more watchable than most:

Thanks again 🙂

Nice work.

What's next?

My neighbour just moved up to a 40% traction engine from his previous 25% - a whole nother level of mechanical fettling to dive in to.