![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

I had a Peter Millard video pop up on YouTube and I've been sucked in again. Found myself watching/rewatching all the tracksaw workshop and comparisons, including the new Macalister and parkside reviews, then a few other tracksaw reviews from skillbuild and others, then hours of googling and pricing up different options. I don't even have a particular project at the moment, but I want plunge saw, daft. Anyway, I reread the tracksaw thread from a couple of years ago but that is now closed, so is it time for a new thread? How are the Titan and parkside users getting on? Tips, tricks, do's and don'ts?

I bought the MacAlister one a few weeks back, after watching the same Peter Millard videos. Primarily to cut down furniture board to finish off a kitchen. So skirting, end panels, a built in wine rack.

Overall really impressed. There is some chipping at the edges, so I may look at a finer pitched blade.

Took a few cuts to get my eye in so to speak. But other than that, all good.

Only negative is that it doesn't have a soft start. So you need to ensure that you have some weight on the rails to stop them shifting.

Oh and the quantity of dust was significant, but I was working outside so not a great problem.

Definitely a blade upgrade seems worthwhile on the cheaper saws, and sound that from the off, before you trim the splinter guard.

Some tips:

If you can't get a clean cut, it's not always the blade, it's sometimes the material. I've got a bunch of blades, one cost as much as the Parkside saw, and some boards just chip for fun. If that happens I clamp the rail to the board and set the depth to 2mm and do a scoring cut first. If it's the underneath that's chipping experiment with the depth of cut. Some say the whole tooth should be visible, others say just 1mm is enough.

Try to get some clamps that slide into the slot under the rail to hold it in place.

Make a cutting board with a piece at the back to rest your workpiece against and a couple of pieces at right angles to rest the rail against, helping to get square cuts without fuss. I even screwed part of a metre rule to the back "fence" so I could get accurate, repeat cuts.

See if you can get a kickback stop to clamp on the rail. If you start the cut with the saw backed up to the stop it prevents it jumping backwards if you plunge it into a board without sufficient pressure on the saw. That is a bit scary when it happens.

Rig up an old vacuum to the outlet to get maximum dust collection and always wear ear defenders.

Crosscut board, Peter Millard shows how to make one, tbh I wasn't sure it would be that useful but seems I should rethink. He shows how to make a set of parallel cut jigs and a rail square too

As for kickback, maybe I've been lucky but in 20+ years using a circular saw I've not had a bad kick. Ok it has a riving knife but it's thinner than the blade. I recently rip cut an old piece of 2*4 that had so much tension the cut was closing and the saw struggling as the blade for clamped, but it didn't kick. I've abused it plunging it to cross cut floor boards and been fine. I do tend to treat all power tools with respect and hold them firmly though.

. I’ve abused it plunging it to cross cut floor boards and been fine.

I wouldn't say thats abusing it, it's one of the saws primary functions to plunge cut, be it rip or crosscut.

On the subject of plunge cuts. I've always found it a bit of a worry having to use one hand to hold the spring guard open, I think some arrangement of operating the guard with the thumb on your trigger hand would be far safer. Even sometimes when starting on a board in a regular cut, sometimes the guard doesn't want to roll open, and you've got to take one hand off to lift it a little bit. Always seemed the bad idea about circular saw spring guards.

I know what your mean about the guards.

To my mind, plunging with a circular saw means starting the cut with only the toe of the base plate on the work piece is not what it was designed for, hence 'abuse'. Miss use probably more accurate though.

I bought a Makita last year to build my campervan with. I felt like a pro using it 😁

I don’t know what track comes with what you’re looking at but I know some of them (eg Evolution) come with short sections of track. I made sure I had 150cm track (x2) so that the majority of cuts just used a single section.

I'm looking closest at the makita. Mafell and festool are very spendy. The Bosch is designed/made with mafell so I expect awesome but I can't find cheap rails (Bosch use the mafell system I understand) it's spendy too. The Makita isn't cheap but I can find it with 2*1600 rails for £395. With some hunting, saw only here and rails elsewhere, joiners somewhere else, I can save enough for a set of the quick action clamps for the same total.

The Macalister comes in a little over half that after a blade upgrade, an extra joiner, extra 1400 rail and clamps.

From what I understand the MacAlister uses the same style of rail as Makita. So you could always go for that with the 1600 Makita rails.

I've only used the two 700 rails joined together a few times but I've not noticed a jump between rails.

One thing to remember is that your rails will need to be longer than the material you're cutting. Sounds obvious but the plunge saw needs to be completely on the rail, front to back, to ensure its true. So you need at least half the length of the saw in the rail overhanging, if that makes sense.

@neilnevill If you're anywhere near Chesterfield you're welcome to borrow my cheap MacAlister to see if it will work for you, before spending on Makita.

So I was a non believer and for some uses they are just not a table saw replacement.

But thay do board cutting very well and hooked up to dust extractors they are a joy to use.

Being a sceptical bugger and due to dropping my Makita Rip saw and snapping the blade guard I popped to lidle and got the 50 quid saw swapped the blade for a proper one I had in another saw and it's a very useful too.

Top tips

Big roofing square for quick set up the yellow Stanley one from toolstation is great.

I don't think it will rip timber down when I have a table saw to carry out that task it's more an MDF/plywood cutting tool for me.

Having said that I should have got one years ago and they are far far safer than a skill saw.

Overall they are great .

One thing I did was get the cheap evolution track with the slide in clamps

Yes makes be sense.

Ta, South London though. Tbh I've no idea why I'm looking past the MacAlister as Peter Millard rates it. Generally with tools I'll buy a mix, tools I use lots I buy decent...DeWalt, Bosch, Makita. Tools I'm to use once or twice or I'm not sure about, I'll buy cheap first. I guess I think I'd use the plunge saw lots, although with no project on the go at the moment, and 3 small kids consuming my time, i can't be sure.

Oh and the anti tip lip on the Makita rails foul the Macalister saw... Or was it the parkside... One of them.

I bought a Makita about two years ago. Best power tool I’ve ever bought. I think it was £325 with two 1500mm rails.

I’m a picture framer and by god, it’s been incredibly useful for making boxes for framing all sorts of memorabilia.

Stock blade is amazing on birch ply, MDT, shite ply, osb.

A dust producing monster mind you.

I’ve got the Makita cordless and love it. Table saw is relegated to the few things it’s better for, mostly it’s become extra bench space.

I got a cheap MFT style top and some bench dogs. Also chopped a spare rail down to 800/600. Now makes it absurdly easy to get perfectly square cuts for shelves, cabinets, etc even in a small awkward single garage.

I’m just a DIYer not something I use professionally every day. Being able to cut quickly, accurately and square just makes everything else way easier.

I’ve got the Makita cordless and love it.

Me too. It's a fantastic tool.

I use a table saw too for repeatability but I always use my track saw initially to break down panels and for where I want a really clean cut.

The Makita has a scoring button so you do one pass with that on at a shallow depth, then go back full depth. The anti-fall onto the floor at 45 degrees button is brilliant too.

I think for diy use,a lot of those ones Peter Millard suggests would be great and infinitely better and safer than most diy approaches.

That white furniture board is bloody horrible stuff to try and cut nicely. I'd echo what BigJohn says above. Take a very light depth scoring cut before cutting through, make the cut very slowly too. Another thing you can do if it's an important cut is to stick masking tape down on the cut line making sure it's rubbed down well with no creases.

When you remove it, do it very slowly at a low angle towards the cut edge.

Track saws are a revelation.

Love mine. Use it for all sorts of different cuts. Definitely don't miss having a table saw. You can make up jigs for quick, repeatable, accurate cuts. Feels safe too.

Only issue is the price of longer track. Joined track is adequate but not mm perfect. None of the cheaper suppliers make longer track and the festool 2.8m is about 5x the price of the 1.4m

I took the plunge (!) and bought a Festool kit. Expensive (a few years ago, so nowhere near current insane prices!), but it's such a nice tool to use; smooth, not too noisy, and dust extraction is fantastic. It feels much more solid and stable than other brands I've tried. Virtually no splintering, even with melamine faced boards etc, although it's advisable to use a sacrificial sheet of MDF, underneath, to help alleviate this anyway. There is so little work to be done, following a cut. In terms of value for money, it's been brilliant, despite the relatively very high initial cost. But because I know what a good tool it is, I end up using it a lot more than if it wasn't so clean and accurate. So that only adds value. I'm not saying everyone should go out and buy a Festool, just sharing my own experience.

Ah yes of course! The sacrificial board would help reduce splintering I can see, so much better to do than supporting the work over an edge or something if you really need clean cuts. I've heard the making tape truck before too.

Don't have a table saw bit might be tempted to make a jig to mount the, largely reductant, circular saw in for such purpose.

How useful is the anti tip lip on the Makita? Hmmm, they depends how often you do bevel cuts, d'oh! I realised I could get 2*1.4m of evolution track, plus the joiners, for £75, almost £50 less than the same Makita. I need to check but I think the Makita saw will run on the evolution track.

I've started creating projects to do....I need some folding doors..... Nothing like going straight in with a tricky job!

I've got the Evolution 2x1400 pack. The whole thing, including bag costs less than the Festool bag! And you can fit 3 rails in it. Peter Millard did a video on rail/saw compatibility a few months back.

The clamps that it comes with need to go straight in the bin though. It works fine with my Festool saw but the splinter guard isn't great. Tip - use Makita splinter guard on all your rails - cheaper than Festool and because it's black it's easier to position on the line.

As far as accuracy, mine is spot on. But I do line it up with my Festool 1400 back to back when tightening the grub screws. After that though I can move it on and off workpieces without it going wonky.

Oh, and referencing one of the posts above don't try plunging a regular circular saw unless you want to be in Sarah Storey's team.

And while we're on circular saws, you can make them as good as expensive rail saws by making a simple fence out of some lengths of chipboard.

I've been using the Bosch track saw, as a plunge saw, for years, although finally took the 'plunge' and bought the Mafell plunge saw kit earlier this year - they both share the same track system.

I pretty much always cut on a sacrificial sheet of ply (on tressles) to minimise break out on the underside edge.

[url= https://live.staticflickr.com/65535/51291937189_4a9e47bd56.jp g" target="_blank">https://live.staticflickr.com/65535/51291937189_4a9e47bd56.jp g"/> [/img][/url][url= https://flic.kr/p/2m9uzWD ]Untitled[/url] by [url= https://www.flickr.com/photos/brf/ ]Ben Freeman[/url], on Flickr

The thing with track saws is, in theory, they don't necessarily need a sacrificial board underneath as the blade is cutting upwards from underneath and on top the strip supports the cut. More so if you do a scoring cut first

It can help though fo shiz, especially with furniture board horribleness.

as the blade is cutting upwards from underneath

But hasn't it had to go down through the material in order to then come back up?

Actually another reason I started using the under board was dust collection, it stops the saw throwing sawdust under the table, the finer stuff of which then circulates in the air etc.

Yes, if you're starting inwards of the edges.

The majority of cuts would likely start outside, pass through and end outside.

Actually another reason I started using the under board was dust collection, it stops the saw throwing sawdust under the table,

Good point 👍

I did similar...binged Millard then bought a Titan about 18 months ago without a specific project in mind. Since then i've built a coffee table, bathroom shelf unit, doors for a TV unit, various shelves and the biggest to date a built in wardrobe/storage cupboard.

It's fine for my needs. Some minor tear out on ply wood but nothing that makes me want to upgrade the blade based on what i'm doing with it.

I ended up buying a mft style top on ebay which came with 6 bench dogs. It's just screwed to my old kitchen worktop 'workbench' in the garage. It makes getting square cuts on small/medium very easy. Well worth the money i paid for it (£50 or so from memory).

I also recently bought a titan shop vack which is great for keeping the dust down - i should have bought it earlier.

Watch out for kickback and always keep an eye on where the power lead is before you make a cut (so it doens't snag, not just chopping through it!).

so it doens’t snag

I use a Festool Midi vacuum with my saws and their hose is ribbed which means it catches on everything. Fine of you can hang it from the ceiling, but if you're using it connected to the vacuum on the floor, it's a PITA and endlessly pulls out of the tool when it catches on the end of the workpiece.

I ended up buying a mft style top on ebay which came with 6 bench dogs. It’s just screwed to my old kitchen worktop ‘workbench’ in the garage. It makes getting square cuts on small/medium very easy. Well worth the money i paid for it (£50 or so from memory).

I made a DIY MFT table, based on one Scott Brown made. Not that accurate, but not bad for a first pass.

[url= https://live.staticflickr.com/65535/50791111697_cd9b3ce212.jp g" target="_blank">https://live.staticflickr.com/65535/50791111697_cd9b3ce212.jp g"/> [/img][/url][url= https://flic.kr/p/2koeHYn ]DIY MFT Table[/url] by [url= https://www.flickr.com/photos/brf/ ]Ben Freeman[/url], on Flickr

[url= https://live.staticflickr.com/65535/51293118765_6c08435127.jp g" target="_blank">https://live.staticflickr.com/65535/51293118765_6c08435127.jp g"/> [/img][/url][url= https://flic.kr/p/2m9ADbD ]DIY MFT Table[/url] by [url= https://www.flickr.com/photos/brf/ ]Ben Freeman[/url], on Flickr

Think that was the first pass, it was too deep so I remade all the sides about half the height.

okay, I'm in! new makita6000J appeared on ebay at £249 so I jumped. 1% topcashback and 0.5% nectar points. excel 3m rail set (2x1.5m plus joiners) as they are exact copies of makita with the antitip lip £94 on manomano with 8% topcashback from that, pair of makita rail clamps from dwtools for £20 delivered. So all set for a few pence unde £352.

I'll be getting some mdf and building a crosscut jig and a set of parallel cut rails. but first...what was it...roofers square?

roofers square?

Yes the big yellow plastic Stanley ones from Toolstation - nice thick edge to them so you can but the rail up against it

based on one Scott Brown made.

Ron Paulk would be turning in his grave if he was dead. 🙂

Ron Paulk would be turning in his grave if he was dead

I think Scott did mention him as being the original source, but never seen one of his videos.

roofers square?

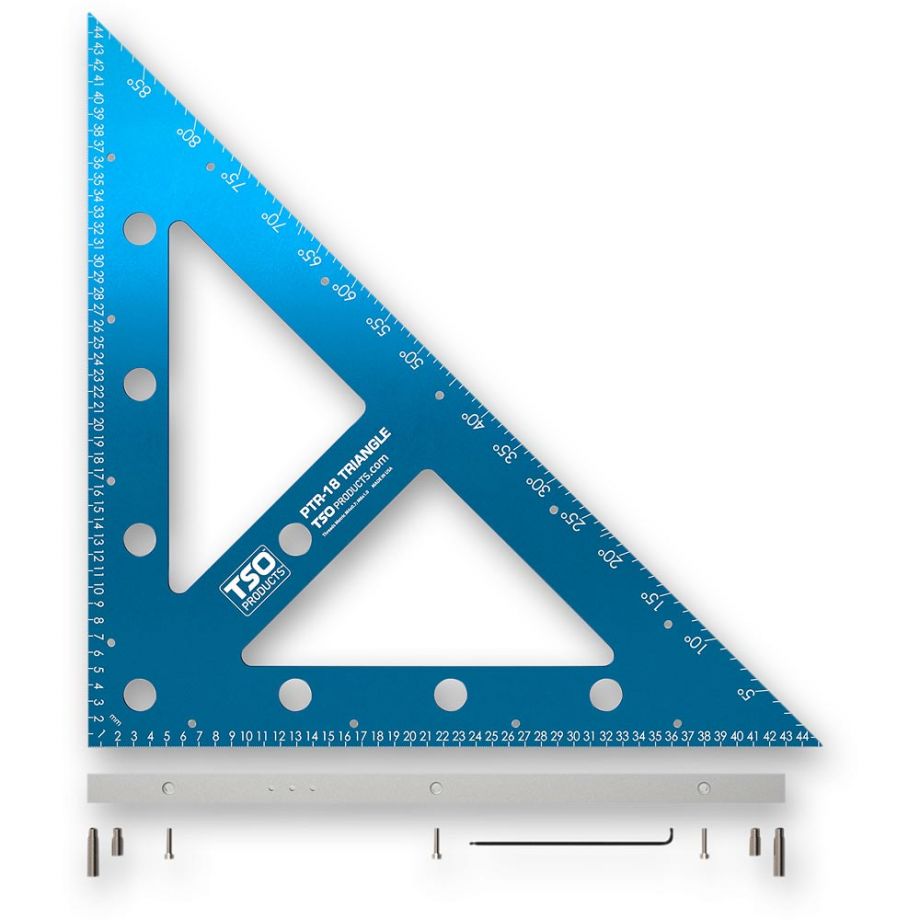

Benchdogs do a nice one for MFT tables:

https://benchdogs.co.uk/collections/precision-triangle/products/precision-triangle-bd450pt

I've also got their rail square for my Bosch rails:

Axminster do an MFT one as well

https://www.axminstertools.com/tso-products-ptr-18-plus-precision-basic-triangle-106357

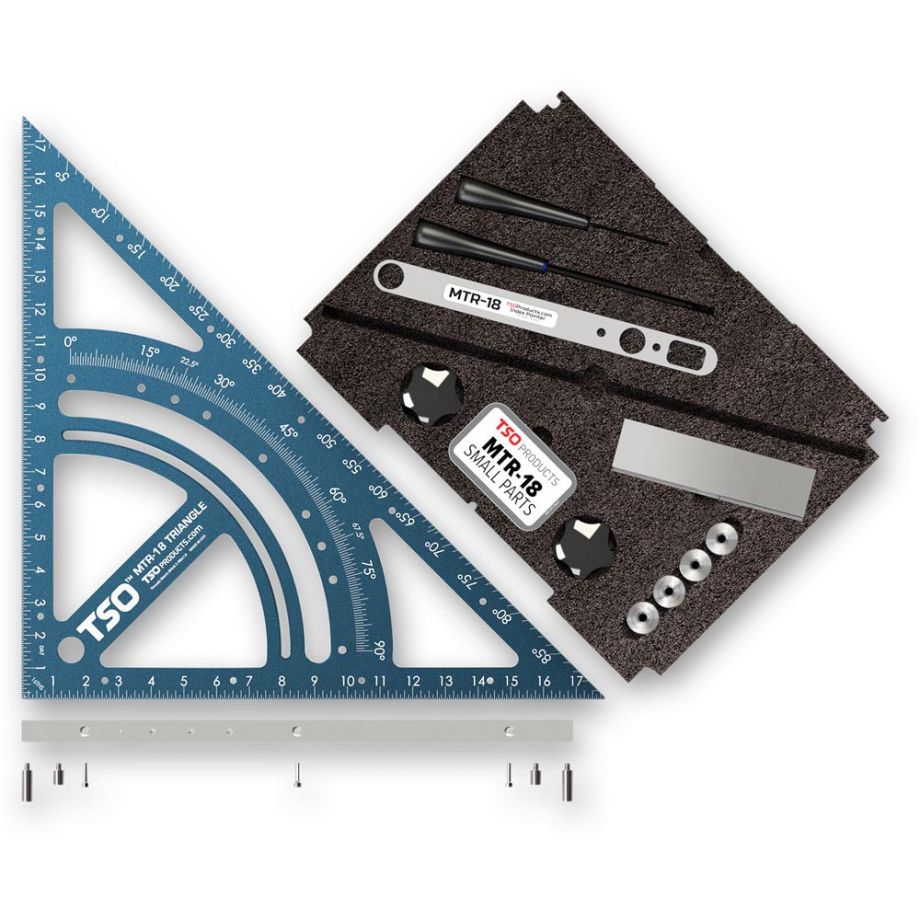

and an even more expensive one!

https://www.axminstertools.com/tso-products-mtr-18-precision-triangle-105204

Actually I lied, the Benchdogs rail square was out of stock, mine was from FC Tools.

https://fctools.co.uk/product/fc-mafell-mf-rail-square

the stanley isn't square according to some amazon reviews (and pics), so a paid a little bit more and bought the swanson 12" +7" twin pack, £25.

If you want a square, don't bother paying loadsamonney on a metal one. My view is that if you're making furniture your tolerance is about .5mm. so go to b&q and buy a kitchen door. That's square. Chop it up to make it lighter, add a bit to one edge to make an upstand and it will give you accurate cuts for years. That's what I use, and I've got nothing against Benchdogs, I spend quite a lot with them, but squares are overrated.

And the "Spinning in his grave if he was still alive" gag was mine on another thread.

Fascinating thread, watching with interest as I’ve also been watching Peter Millard and considering a track saw for home hobby use. Got some kick boards to make for redoing our kitchen and am always struggling with decent accurate long cuts with a circular saw. I have a load of Mikita lxt stuff so am tempted by their tracksaw despite it being more than I need.

Some reviews said the triton one was good re track etc but the saw wasn’t a true plunge saw, more of a circular saw that ran on track.

their hose is ribbed

Fnaar!

Got some kick boards to make for redoing our kitchen and am always struggling with decent accurate long cuts with a circular saw.

Track saw is a revelation, anyone can cut 2m with less tham 1mm error using one. Previous to getting my old Bosch one I was using a jigsaw against a metal edge clamped to the work, night and day difference! Track saws are just amazing for perfect straight edges.

These are good for that.

HoseWraps

An old MTB innertube is just as effective, yet much, much cheaper.

An old MTB innertube is just as effective, yet much, much cheaper.

Yes, but part of the fun of it all is having an excuse to buy nice tools. I have far better tools than I'll ever be able to use at cabinetry!

Lol! True, true. Although I do use pretty much everything I buy. Because I often realise that I need a particular type of tool, when doing a job where such a tool would be really bloody useful. I then buy said tool (often once I've actually completed said job the hard way), where it then lies for a while before being pushed into service. Things do get used though, I'm not a hipster. Side rebate plane; there you go. Such a useful, simple tool. Bloody none in stock at the moment though. 🙁

I feel there are a couple more upgrades to my tool box needed. First some trestles. The days of supporting large sheets on scraps of 2*4 on the drive and crawling around on hands and knees as I push my circular saw along my clamped straight edge need to be gone for ever. I'm too old, my back won't cope, nor knees, and I'll cry if a balls up led to a plunge saw blade to concrete driveway interface. For comfort and accuracy, trestles I think. Any reason to get anything more than cheap ones? They would do for sheet material and doors etc wouldn't they? Or do I do Peter Millards trestle project? Hmm. A few simple projects to get some saw practice seems sensible maybe, but then a sheet of plywood is as much as a pair of cheap trestles.

I have a Titan vac. I think I'll have to hang out from the garage roof so the hose is not a faff.

Can someone explain to me when you use / need the MFT table ?

I do have a plunge saw, the erbauer model, wish I’d bought the makita cordless and not been so tight.

Can someone explain to me when you use / need the MFT table ?

It's just really handy as you can stick in some Dogs and suddenly you have something to but work up against, or push a clamp through a hole and clamp a piece of work down. Or add a fence + dogs and you have a fence to make repeat cuts against.

It's not a miracle solution in itself, but it just makes lots of things simpler.

Axminster have some nice videos for their MFT tops showing what you can do:

https://www.axminstertools.com/ujk-technology-multifunction-workbench-for-twist-dogs-717979

Cheers flaps, I'll take a look at that. So it's a bit like the holes and pegs that many workmate tops have.... But on steroids.

Btw, anyone got useful tips for DIY router table and jigs? Do we need a separate routerists thread?

So it’s a bit like the holes and pegs that many workmate tops have…. But on steroids.

Yep, then add in fences....

Lots of nice clamps

Rail squares with dogs

https://www.youtube.com/watch?v=qik-UoZUAgg

Is a proper rail system that much of a game changer?

I have a little 20v Worx plunge saw and for straight cuts I just clamp down something with a straight edge to the workpiece. I have a longer jig made with leftover laminate flooring which stops stuff wandering one way, and concentration and patience stops it wandering away from the guide. Am I missing something?

The MFT system , the biggest plus point is being able to cut perfect 90 angles

in moments.

So - once you cut a strip off your straight board you want to cut the ends square, with the strip pushed against 2 dogs you can lay the rail against another dog and you have a perfect 90 , its harder to explain than to do, it gives the plunge saw the extra to effectively replace the table saw for many jobs, and with thought and jigs almost all jobs.

It has many uses in marking out, work holding and there are lots of affordable ways to start now with just a top and dogs - excellent offers around for a top and dogs.

Lookup rs_cnc_designs on ebay for a top and 6 dogs

Is a proper rail system that much of a game changer?

If you have to make a lot of repeat cuts, saves getting out my table saw and using it's fence.

Is a proper rail system that much of a game changer?

Yes. I made a couple of straight jigs to use with a normal circular saw and it's fine, better than just the saw, but the rail is a huge step up. You don't need clamps so alignment is quicker and simpler. It's much more reliable and gives more consistent straight cuts. Easy to add jigs for repeat cuts. Easy to move it a tiny bit a shave a fraction off. Better finish too. Depends what you are making as to whether it is worth it to you but it is a lot better

Given how cheap MFT clones are on ebay / Amazon (around £50) it's a pretty cheap investment.

https://www.ebay.co.uk/itm/324698187476

For comfort and accuracy, trestles I think. Any reason to get anything more than cheap ones?

I'd say not. I use cheap workmate copies. About £10-£20 each. Quick and easy to set up. Makes cutting big sheets a lot easier. For extra support I put an old pallet on top. No heartache if you cut into it and it can be left outside. You can pick them up free too.

I have a set of these Stanley trestles which are brilliant. They fold up and clip together neatly.

I also have a set of the regular folding plastic type.

The Stanleys at the top can take more weight and have a longer support, although you can stick 2x4s into the slots on the plastic type.

I screw bits of 18mm mdf to the tops from underneath with brass screws, giving me a nice flat surface that I can cut into with my track saw nae bother.

Can someone explain to me when you use / need the MFT table ?

Really the thing they are useful for is repeatability - rather than measuring and marking up every cut one piece at a time its away of setting up to make the same cut again and again. So its a time save.

Is a proper rail system that much of a game changer?

I have a little 20v Worx plunge saw and for straight cuts I just clamp down something with a straight edge to the workpiece.

Again - its a time save. A rail system is just faster - it doesnt allow you to make any cut you couldn't make with a ripsnorter and a straight edge its just quicker (and plunge saws with extraction are also cleaner so thats a time save too)

So in either case its really a question of what matters to you in terms of time. Some people are making things as a way of spending time and some are doing it as a way of making money and are therefore looking to save time.

If you're making things for a hobby then doing things in half the time just means less time doing your hobby.

the stanley isn’t square according to some amazon reviews

Interesting - mine is. I've had it for about 10 years though I think so maybe there have been good and bad batches

If you’re making things for a hobby then doing things in half the time just means less time doing your hobby.

I only mess about for fun, but everything takes way longer than I expected, so anything which saves times is worth it (for me). I mainly work outside now, so I loose half an hour setting everything up on tressles outside the workshop and getting all the tools outside etc, before I've even started. Then the same to clean all away. I was getting sick of everything being covered in dust in the workshop, even using a vacuum attached to everything.

Only half an hour? Fooook, I waste half the day setting up and spend the rest clearing away!

Storing all this stuff, mft and trestles etc, becomes a job and a half. I've a large tandem style double garage and thanks to a huge storage and tidying project I've reclaimed the half the car isn't in, I hope to keep it though and not have to negotiate a pile of junk to get to every toy, tool or material.

The plastic type trestles were my first thought, might stretch to the top ones though if they fold away more neatly.

As for circular saw against staight edge there what I did for the last 20+ years and managed. Although since the motor on my saw overhangs the base plate I could only use the blade side edge against a rail so trimming a thin piece from a sheet could only be done using the saws own fence. I thought about making my own rail system for it, then looked at buying rails and base plate add ones (skil do one, and someone else) but they cost as much as the Macalister or workzone saws and still not as good so I've just gone the whole hog. Or what I thought was.... But seems I need an fst, dogs, clamps, clamps for the dogs, squares, clamp on squares, dogs for the squares, a smooth sheath for my ribbed hose and, and.... Well I've more then I need I guess!

a smooth sheath for my ribbed hose

Knyuck knyuck! Chelp!

I use those plastic Stanley trestles, I think they're great. The slots fit CLS timber. Cheap from B&Q. That means I've got a 2.4m long bench, I stick my MFT on top and with a couple of offcuts of 18mm board to support the longer pieces I can do anything.

And as for the hose getting snagged, Festool make a handy deflector for hose and cable that you place at the end of the rail. But I made one from an old paint roller tray that worked too.

And a final thought (for now) Don't get upset that you bought "an inferior" version of any tool. Tools fall into 4 categories: 1) you can't do the job without it 2) you can do the job quicker with it 3) you can do the job to a higher quality with it. 4) I really really really want it because it's expensive and all the big boys on YouTube use it.

I've got a few Festool which I mostly bought for 3) but with a bit of 4) but if I don't know I'll be using it a lot I'm fine with Erbauer or cheaper. My impact driver, which I bought years ago is an Erbauer. It's in daily use and I wish it would break because then I could justify getting a premium brand. Same with my JCB router!

But seems I need an fst, dogs, clamps, clamps for the dogs, squares, clamp on squares, dogs for the squares, a smooth sheath for my ribbed hose and, and…. Well I’ve more then I need I guess!

……

I’ve a large tandem style double garage and thanks to a huge storage and tidying project I’ve reclaimed the half the car isn’t in, I hope to keep it though and not have to negotiate a pile of junk to get to every toy, tool or material.

🙂

I’ve got some of the cheap plastic trestles and they’ve had some really heavy solid timber worktops on them with no problems.

The Bora Centipede things look ace though if you can spend more, no worries about supporting in the right direction/places. https://www.keybladesandfixings.com/collections/bora

If you’re making things for a hobby then doing things in half the time just means less time doing your hobby.

Or getting twice as much done in the limited time you have. Cutting MDF isn’t the hobby in itself, making nice fitted stuff for my house is.

Being able to quickly, repeatably cut things to the right size and square is like having a superpower after years of faff with not-quite-right bits I’d cut using a circular saw.

For me the great beauty of the rail saw is that I can work off a pile of sheets on the floor. No need to worry about supporting offcuts or the saw falling on the floor (can happen if you've set up a bevel cut); just shove a scrap of 6mm board under the cut to protect the material underneath. I have two 1400 rails and an 800 one which is handy working in tight spaces. I don't use squares or jigs as the workshop table saw gets used when I'm back off site.

Rail saws are actually great for scribe cuts as a series of short straight cuts works fine around most curves, much faster and neater than using a jigsaw, handsaw or power planer.

Yeah big John and maccruiskeen sum it up. I don't need this, but it's a bit of treat myself. Other than my large chainsaw this is my most expensive power tool. I've tools to do many jobs but got a real mix ...bosch blue cordless drill (x2) and impact driver, DeWalt corded big sds+ drill, this plunge saw and both the Stihl and husky chainsaws I consider quality tools for me as a DIY guy and festool mafell Milwaukee I'd love but not enough given the use id get. Then I've tools like the 25 year old black and decker circular saw and a b and d Jigsaw, just about old enough to be from before b&d went to pieces and an almost as old biggish old corded hammer drill from the Wickes pro range... Good value tools that have paid for themselves many times over and do okay but not special type tools... Then power devil angle grinder, parkside multi tool, performance power router and similar brand chop saw are cheap but have done far more then I could have imagined. The router and the multi tool I'd upgrade to Bosch/Makita quality in an instant if they ever break though. Hand tools agree a similar spread, a teenie bit of snap on, king dick, stahwille, (old but quality) a similar amount of Halfords pro and Stanley from 50+ years ago before they went to pieces, and a load of pretty cheap sh**, but generally it's been for enough to do the jobs I've asked of it.

I can't think of any cheap tools I regret buying, a few I'd buy better now I've more money and know the tools use, but that's it. Similarly I don't regret the better tools I have, they've been well used and have made jobs a pleasure

It's arrived! I need to fit a plug. It was cheap as it's obviously European stock, with a 2 pin plug.

Thankfully I have a plug, and the tools needed to fit.

Hmmm, do I have a problem? Both the rails (Excel 1500mm) are slightly bowed, one more than the other. If laid on a flat surface the worst one is maybe 5mm up off of it at either end. Saw seems to run along each (haven't tried joining) and the rails flatten as the saw passes so probably okay? Or should I return them?

Or should I return them?

Yes, return. You need your rail reliably straight.

Also if it is curved that way you risk it moving while cutting. If it was second hand I'd have a go at gently straightening it but as its new you might as well get it replaced

Yeah I can see it won't sit reliably without clamping. As you say, if I'd bent it, I could likely straighten it, but I didn't. Packaging was fine which had me worried.... Anybody else got excel rails? I'm fearful they are all a bit bowed and the free quid extra on Makita will be a better bet.

report raised with seller on manomano, hope they get back to me tomrrow, that they collect the bowed rails, and i get some straight ones quickly.

btw, i can see the handiness in a short rail. anybody interested in literally going halves on a long one?

The holes on the old black and decker workmate were only ever there to use little plastic stops to hold wood or other materials steady for working on. MFT's are , or rather the holes in them are there for accuracy and squareness when machining or clamping. Design is simple but very accurate.

The Bora Centipede things look ace though if you can spend more, no worries about supporting in the right direction/places.

I have a Bora centipede - with their "foldable" MFT style top. Very happy with it - I haven't used the dog holes yet (dogs on order), but it terms of its ratio of packed-down size vs surface area, it's great.

Tools4trade (the actual sellers on Manomano) have issued a return label after I sent a photo so it'll be a few days but looks like they are processing things fine.

I was cheekily hoping they wouldn't ask for the bent rails back and I'd try and straighten them. Probably unsurprisingly they do want them back though.

The Makita has a scoring button so you do one pass with that on at a shallow depth, then go back full depth. The anti-fall onto the floor at 45 degrees button is brilliant too.

These features are present on the option i never see mentioned which is the erbauer one.

Evolution do the cheapest 2x1400 track kit for longer cuts but you lose the anti tip groove (but the saws run absolutely fine on it.

Peter Millard also points out the evolution track has both slideway strips blade side of the rib, and some saws can tip over a bit as a result. He says it's a problem he has never had, but a subscriber has.

Whilst I’m laid up having bust my hip and lower back at the start of this week, can someone recommend a setup for a halfway decent MFT setup. I could do with a little bit of tool related retail therapy.

I don’t have saw horses, if they’re needed.

Won’t be able to use it for a good few weeks, but that’s not really the point.

can someone recommend a setup for a halfway decent MFT setup.

How long is a piece of string?

From off the shelf original Festool: https://www.axminstertools.com/festool-mft-3-multifunctional-table-with-accessories-702780

To Axminster home brew: https://www.axminstertools.com/ujk-technology-multifunction-workbench-for-parf-dogs-717978

to buying a piece of MFT clone board on Amazon for £50 and making a bench out of it....

Again, loads of places make the dogs, Axminster sell then or https://benchdogs.co.uk/

As above there are many options. notes from me - as diy not pro:

I have the UJK (Axminster) version - just the frame and put an rscncdesign top on it which made it good value , but its extremely heavy , rigid and the supports for the top that run inside do get in the way - so its a fixed or movable type bench not portable.

I also have a knock together rscnc rough ply - that is portable and not bad but needs care as its very tight when put together.

There are many more options these days , i think I would go for the type that has a folding base and slots together - again in wood , paint it your own colour.

These are all budget+ that get you going with something a bit better than just a top and 4 dogs for which there are a multitude of DIY designs - a nice one by a Canadian guy that I cannot find a link to that has folding legs a wheels to transport. edit - found link https://www.danpattison.com/mpt

If you have the money and value the resale option then a genuine Festool mft3

is OK but not very rigid in my opinion, a bit over the top.. for DIY.

The diy systems for making your own tops are really for custom setups or folks with a lot of spare time considering the price of cnc tops and how long they last.

Dogs and jigs are plentiful at all budgets.

Thanks guys

@BigJohn nice setup. May blatantly copy that.

I’ve bought the saw horses from screwfix https://www.screwfix.com/p/stanley-folding-saw-horses-69cm-2-pack/82233

Where did you get the MFT top from, it looks like the larger slots at the outside can take normal clamps, which would be very handy.

The top came from Benchdogs a few years ago but they don't do them any more. Yes it's a biggun but I do wardrobes so need to be able to work with 2800 X 610 boards. That's why I use the long supports, I can slide the mft and workpiece up and down to cut the board down without keeping turning it round.

The big slots are more of a nuisance than a help, as I have clamps which fit through the holes as well as in the rail slots. The Axminster ones are much better than the expensive festool ones. But the slots are handy for lifting it on and off.

MacAlisster MSPS 1200 selling for £80 at Screwfix is it worth a punt?

Nothing can match a Stihl masonry saw so sometimes the more expensive is the best, a Makita masonry saw works good for 6 months then gives you problems whereas Stihl 3 years other than rope repairs , filters never been looked at as no loss of revs