![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

I generally have a lot of flatpack ikea type furniture that is getting pretty shoddy, and looking around at replacing it with any even half decent more solid furniture costs a bloody fortune.

I was considering starting to build my own, start of with a couple of simple projects like a coffee table. then a bed etc. (actually might be a good idea tp start with building a good work bench) Probably won't save any money really but could be a bit of a hobby and quite satisfying building my own stuff.

But looking at wooden furniture projects on youtube, it seems that the yanks all have fully equipped woodworking workshops at home, which I just cannot have, I will mainly need to use the cellar and can't/won't have anywhere near the equipment they have.

So multiple related questions

Does anyone build with more basic equipment successfully?

What tips could you give for doing away with table saws and stationary planers etc

Where do you buy decent wood that is finished?

Where do you get inspiration for your projects?

And what tools would be considered essential to start out? (major tools/power tools rather than the small stuff)

And what tools would be considered essential to start out?

I would think a sliding mitre saw would be great. I've not built furniture but any projects I've tried the biggest problem has always been cutting at slightly funny angles. You can build jigs to do it but it's much quicker if you can just set a saw and do several identical cuts

The essential piece of kit is a circular saw with a guide rail. I now have a Festool one with a multi function top which enables me to make fast clean accurate cuts. However, I'm a professional and you can achieve similar quality with a cheap B&Q circular saw and some self-made fence rails and jigs made of chipboard and MDF. I don't need a table saw, chop saw, mitre saw etc. I just need a pair of trestles, a couple of lengths of CLS to support my work and I'm fully mobile.

I now have about 3 drills and an impact driver on the go at one time, but if you don't mind taking a few seconds longer you just need one drill driver.

Look at the Kreg Junior kit. I make high end furniture using it, along with 18mm Melamine faced chipboard. Don't sneer, the Egger board is excellent. If you get the Kreg, invest in the clamp and the right angle clamp.

Does anyone build with more basic equipment successfully?

Yes, since humans started making furniture before power tools were a thing! Look up Dick Proenneke on YouTube and see what he built with some basic handtools alone in the wilderness.

What tips could you give for doing away with table saws and stationary planers etc

Hand saws - ripping and cross cut for cutting down to size, tenon saw/pull saw for fine cuts. Hand planers of various types, start with a no.5 jack plane as an allrounder.

If you want to stay with power tools then a good plunge track saw will do a lot of what a table saw will do, i.e cut down material to size accurately and take up no space.

Where do you buy decent wood that is finished?

What do you mean by finished? Look up timber merchants and suppliers near you. I would start out with some basic plywood projects to get to grips with your tools. Good timber merchants will cut these down to whatever sizes you ask for.

Where do you get inspiration for your projects?

Furniture I've seen elsewhere, furniture making books that were in my family growing up. These days YouTube has lot's of stuff, one of my favourites just now is Ishitani Furniture, he produces such quality furniture using methods that I'd never be able to do unless I went full time learning them, but you can take the final outcome and figure out easier ways of making the joins etc.

And what tools would be considered essential to start out? (major tools/power tools rather than the small stuff)

I'd start with a good plunge saw and track (Bosch GKT 55 GCE for example), a smaller laminate trimmer style router (Bosch GFK600 for example) and a sliding mitre saw and a drill & driver combo. Don't neglect dust extraction either.

I'd also add a pocket hole jig and a lot of clamps, start with making a workbench then I'd make some plywood cabinets (kitchen cabinet size) for the workshop/garage, start with them as open cabinets then you can add doors later as a seperate project.

Once you get into making furniture for the house, you can make some nice stuff from plywood with a good veneer and real wood trim. Start with more basic items that you won't mind replacing in years to come as you get better and better and maybe move onto real wood (not that there is anything wrong with ply furniture, it's great).

To start I built a wardrobe to fit under a collared ceiling and bedside cabinets all in the Ikea Hemnes-style

The local timber merchant cut MDF sheets to a cutting list, some planed 2x2 and 1x1 and that's the heavy machinery done with

A smoothing plane, cordless drill, hammer, tenon saw and a dowelling jig (or a biscuit jointer/pocket hole jig) did the rest. Paint to suit

Oh vaguely on topic of the op...

Electric planer, useful bit of kit for a very amateur or a good way of losing my fingers and stick to manual one?

And what tools would be considered essential to start out? (major tools/power tools rather than the small stuff)

Really... a lot depends on what your ambitions are in terms of the furniture you plan to make. Certain styles of furniture are designed around the way you can work with hand tools. You can't really make a Wheel-Back chair with a plunge saw for instance.

Similarly you won't have much used for a spoke shave if you're making a Ladderax. More contemporary designs tend to revolve around engineered boards (plywood etc) rather than lengths of timber - and being that the boards are flat and straight and square to begin with then designs utilising those boards favour power tools are similarly suited to make flat, straight, square cuts.

Some designers design furniture that is almost tool-free. Enzo Mari published a book call 'Autoprogettazione' in which all the furniture (chairs, tables, shelves, beds) can be made with just a hammer and a saw

And what tools would be considered essential to start out? (major tools/power tools rather than the small stuff)

Power tool wise - A plunge saw is very space efficient - with a table saw you need room for twice the length of the board you're cutting to be be able to feed it through the saw. With a plunge saw you don't need more space to work that the board itself. They are a great way to get big boards into manageable sizes - even though I've got a massive, sliding bed table saw in my workshop I cut stuff into manageable sizes first with a plunge saw.

Where plunge saws have their limitations is when you get down to small sizes. A table saw really helps there - working on small elements - but you can get a two-in one tool in this respect - a few manufactures makes a Mitre Saw that doubles as a small table saw - often powered by an induction motor so they're quiet too compared to regular mitre saws which can be quite barky. So power tool wise - that combo mitre saw and plunge saw will cover an awful lot of scenarios and take up very little room

And get a dust extractor.

My dust extractor died last week and I replaced it with a Titan from ScreefSc that has a power take off. Saved £300 over the Festool and I'm very happy. Except it's not Festool.

I would echo the comments about plunge saws. They're brilliant. The Titan one at Screwfix has good reviews for the money. Plenty good enough for starting out.

Have any evening classes near you? Doing that you'd have machinery, hand tools and instruction all at your disposal. Might be good until you know what sort of stuff you want to make .

It depends some what on the type of house and what style of furniture you like, rustic and industrial is pretty easy with lots of cast legs brackets etc

New untreated and unbanded scaffold boards are easy to work with but ypu will struggle to get a "posh" finish.

Tools - cross cut saw electic planner, belt sander and a rechargable + a mains hand drill, decent hand saw, drills and forstner bits and a decent chisel all help.

Just built a shaker style kitchen from scatch out of scaffboards, carcassing timber and some ply for draw liners, looks great in a 17th centuary piggery but would look shite in a victorian terrace. Its only small but didnt spend 250 quid on timber.

Like others have said it depends on what style of thing you want to make - and how quickly you want to do it. You don't need power tools for most things but its a lot quicker and needs less skill to get e.g. square clean cuts. I like working with hand tools and only make the odd thing over quite a few weeks (couple of hours in the evenings) so don't have many power tools (don't have much space in the garage for big tools either)

Paul Sellers on youtube is good to see what can be done with hand tools (OK and in his case 30 years practice)

Look at the Kreg Junior kit.

I've got the Kreg Jig R3, great little piece of kit.

Doing the joints is the hardest part and essential for making a decent item. You really need to take time and care fashioning a dovetail, for example. I've made a coffee table from big slabs of wood but for finer stuff you really need to practice getting the cuts accurate and angles exactly right - for that I reccommend starting with hand tools ie a tenon saw.

don't know about the UK, but Lidl France have some power tools on special on a regular Basis, managed to buy a very nice plunging Mitre Saw with rail for less than 80€

I'll buy a decent cordless drill/screwdriver and some pocket jig for 45° holes and tenons. Then you can build from here.

Look at morediycreator n youtube and insturctable. Start small (box and shelves) and built from here

HTH

There's good non-Kreg options now for pocket holes, been meaning to pick up one of these to supplement my little Kreg kit: https://www.aimtools.co.uk/products/105418-pocket-hole-jig-kit

Agree on plunge/track saws, you can get great results for not a lot of money. Fancy MFT-style things with stops and so on make cuts easier to set up but easy to mark out by hand and just cut along the line. Look up Peter Millard on youtube, he reviewed the cheap Titan tracksaw but he also does lots of custom cabinets and the like in a tiny little space without massive great machines.

There's plenty of timber suppliers (especially the ones that stock a good choice of hardwoods) who will cut & plane to whatever you need.

Doing the joints is the hardest part and essential for making a decent item. You really need to take time and care fashioning a dovetail, for example.

Or buy a router and a jig and knock up 20 dovetail joints in few minutes...

clamps..... lots of clamps.

I currently attend a council run wood working class. Essentially we get the use of a school's wood workshop for an evening a week. Just having the space and work benches is worth it. Tools are basic but good as they've got to last use and abuse by many kids. Might look to move onto somewhere with more advanced tools soon though.

See if there are any Hackspaces/Fab Labs/other community workshops in your area - when I lived in the Midlands there were a couple near me and they were VERY useful - made loads of stuff at them.

Ah - as above post really.

Dude... Good on you for getting into this !

If I get my own place, I'll be doing similar!!

I love woodwork etc... I'm thinking of making a king bed out of scaffold and planks .

I made my son's bed several years ago...

Tools I find REALLY useful are a sliding mitre saw (laying decking at the mo, and it's the best £120 spent ever!) .. I've a little worx plunge saw too .. It's great for small projects like kitchens etc... I'd love a decent rail festool or the like... Might invest in one if the need arises ...

Bosch Pro drill driver is great.. I've a cheaper drill as a second drill. I generally borrow a torque driver when I need one (decking again) Add I don't need it that frequently .

Sho us what you make

DrP

I would have said router and circular saw, but have been converted. It's now router and track saw.

You can cut very neat mortise and tenon joints, half lap joints, etc. with a router and some simple home-made jigs; plough out rebates and slots; and round over edges or machine little moulded details that transform things from looking home-made to professional (IMHO).

A circular saw and a guide works OK, but a track saw is SO much quicker and seems easier to keep accurate. Lidl / Aldi have the Park Tool ones on special every now and again for about £70. Can also be used as a plain old circular saw if you wish.

Sliding compound mitre saw is also incredibly useful. Also stuff like jig-saw, random orbit sander, power plane, etc.

Watching 'New Yankee Workshop' when we first got Sky TV is what set me off - it's excellent for showing lots of different ways to make things. Norm has a fantastic workshop, but most of what he does can be done with a router and a circular saw. Haven't done anything in a while, but these are still in use (the blanket chest did get a top and another handle, but I don't have any photos, and I'm b****ed if I'm going to tidy the bedroom up sufficiently to take a photo now!)

[url= https://farm2.staticflickr.com/1941/31535566738_b250c09f70_o.jp g" target="_blank">https://farm2.staticflickr.com/1941/31535566738_b250c09f70_o.jp g"/> [/img][/url][url= https://flic.kr/p/Q3G2iU ]Blanket chest[/url] by [url= https://www.flickr.com/photos/40141861@N00/ ]tillydog[/url], on Flickr

Reclaimed pine drawer fronts, plywood carcass & 'new' pine ends (drawers were done with a home made dovetail jig)

[url= https://farm2.staticflickr.com/1966/45411192381_eda1b94a34_o.jp g" target="_blank">https://farm2.staticflickr.com/1966/45411192381_eda1b94a34_o.jp g"/> [/img][/url][url= https://flic.kr/p/2cbQeoM ]Hall Table 2[/url] by [url= https://www.flickr.com/photos/40141861@N00/ ]tillydog[/url], on Flickr

[url= https://farm2.staticflickr.com/1932/45411195821_efe804c926_o.jp g" target="_blank">https://farm2.staticflickr.com/1932/45411195821_efe804c926_o.jp g"/> [/img][/url][url= https://flic.kr/p/2cbQfq6 ]Hall Table[/url] by [url= https://www.flickr.com/photos/40141861@N00/ ]tillydog[/url], on Flickr

This used to be the bench top in the chemistry lab at work. I hoped it was teak, but I think it is iroko.

First thing I need to do is have a good clear out of my cellar room. Then my first projects will be kitting out the work area.

I am going to try and stick to makita battery tools as much as passible as I already have some of there stuff, and it makes sense to stick to the same platform. Would be nice to have a jointer/plainer and a mitre saw, I will have to keep an eye out for second hand gear over the next few months as costs could easily spiral out of control. Same for lots of clamps and small stuff that just make life so much easier, they seem to use loads of them in the videos I watch on youtube, and it would be easy to spend 500 just to get a good supply ready.

It will probably be a few months before I actually build anything as I get some suitable kit together, but I am actually quite excited to see what I can do.

I've built quite a bit of furniture - mainly built-in wardrobes, shelves and cupboards etc - which can be quite a challenge inane Edwardian house as the floors aren't horizontal, corners at 90 degrees or ceilings level so learning to use things like bevels, spirit levels to strike your levels / datums and working from there. It takes a bit of time and practise to make something accurate and square - even making a simple bookcase from a sheet of 8'x4' furniture-grade plywood would be a good start using a saw, router, electric plane and belt-sander. Lots of places will cut your sheet into manageable sizes, so you're not having to remove huge amounts of material. Investing in a decent adjustable square for a start - one that is 90 degrees, not 89.5 like most in your local DIY shed.

What are reputable brands for things like squres (as above, that are actually 90deg) hand saws, drill bits etc?

Am following this thread with interest as I'm making a workbench for the garage at the moment. Plunge saw looks like a great investment,

Si

You can make your own clamps to save much £££s, especially larger ones, plenty tutorials online.

Learn to check your square as even good ones can be knocked out.

Main bench is a pair of height adjustable folding trestles from Screwfix, maybe cheaper elsewhere, top is 12mm ply about 6x3, easy size to move/transport, with a grid of stiffening ribs glued to underside that also locate the top of the trestles, additional ribs of ally channel length ways. Crossbrace at knee height carries a double layer shelf, 50/60mm apart, lower space for hand tools, power tools fit on top of shelf but keeping your work area clear. Whole thing takes 2 minutes to put up or take down and takes little space when not needed.

Set the height lower for cutting full sheets, higher (more comfortable) for smaller cutting and assembly work, sacrificial 2x1 are longer then the bench top, with glued end stops locate on to top for using rail saw and can also be used as back stop too. Saves ripping up the top of your bench when cutting with the track saw. The ankle height crossbraces are weak, if you copy this set up, I suggest you would want to look at reinforcing those before they get all bent, i ended up welding some box section on instead.

Mitre saw should be at least 216mm blade and sliding, get one with a depth stop and you will have the quickest route for cutting tenons. My saw bench is an old massage table that someone chucked out, so again, folds flat in about 2 minutes.

Routers are handy tools, but the bits soon start to rack up costs, cheap bits are a waste of money. Belt sanders are good but I prefer 150mm random orbit sander for most sanding jobs, selection of different grades and backing pads cover most situations. Decent workshop vac with power take off is essential, especially in a cellar.

Have a look at the Trend Snappy range if you only have a single drill to start, quick chuck goes into drill, then you can easily swap any 1/4 hex drive bits with the ball detent groove in a second. Sets of pilot bit with countersink and clearance drill bits, drivers, plug cutters, spade bits, auger bits all swapped without having to loosen and tighten the drill chuck.

As for hand tool brands, Stanley and Irwin are okay for most, Bahco are slightly better quality, Hultafors make some good tools, Vaughan for pullsaws, all the blades fit any of the handles. For clamps, you can make your own, plenty on Youtube, you could look at making something like the Klemmsia cam clamps as an early project in its own right, get your accuracy and finishing skills some practice. Decent chisels and hand planes can be found second hand may need restoring but much better quality than cheap modern versions, and you will need to learn how to keep them sharp. I prefer normal 2H, or above, round pencils for accurate marking out, and you can buy a box for cheap on the usual websites.

If you are in an area that is getting gentrified, look out for old buildings being refurbed, it's amazing what some people will chuck in the skips. Remember it's still their property even if it's in the skip so act accordingly.

^ * Routers are handy tools but not at all forgiving, to either wood or flesh,

Neil, how do you cut tenons with a mitre saw?

Sorry, don't worry just YouTube'd it.

Great thread what plunge saw would people recommend? Most of my kit is Makita cordless, is the lxt plunge saw worth the cash over a budget titan?

Plus numpty question. What is the best way to attach a Henry to dust ports? Must be a better way than duct tape, bought adaptors but they don't stay in with tape. Adds time and faff to the job

I've just started watching the woodwhisperer on prime seems good for a newbie

I've got a Festo saw, no experience with either of those.

The best adaptors I have found are Triton EU standard 35mm diameter, you can usually find somewhere selling them for about a couple of quid each. A good fit for the ports on Bosch, Makita and Festool.

I have a number of these adaptors which stay on the tools in use, then the female connections are all one standard size and you just need to make that a good fit. If the fitting on the end of the hose is too large in diameter, take some material off in a taper, rasp, file, sandpaper etc, if too small build it up with some wraps of insulation tape. Best to check the size of what you have got, I think Henrys have an odd sized diameter hose end.

Some tools have odd sizes, sometimes plumbing parts work. Solvent weld waste pipe fittings can fit some tools, may need some modification. I also use flexible rubber couplings for both 32mm and 40mm waste pipe, as push fit joints no need to use the jubilee clips

You can get sets of multi diameter adapter stubs on eBay to join power tools/hoses/vacuums, and you can tweak the diameters if necessary by adding a few turns of duct tape. It's worth putting a cyclone separator in front of your vac to catch all the sawdust and chips. You can buy them ready made, but I followed some internet plans to make one from an old paint tub and scrap. Look up Thien Cyclone.

Did anyone mention plunge saws...? I can recommend the Screwfix Titan saw. Probably the tool I use more than anything else, and fantastic if you have to work in the corner of a garage.

I just got a set of Japanese pull saws, which have been a revelation; I'm doing half way accurate manual cuts for the first time in my life.

In a previous post I mentioned using a local council run class and this is at a school. The main bonuses of this is the availability of decent hand tools and the space to work in. However the power tools are not good. They are pretty inaccurate and limited to band saws and belt/disc sanders. This is a school workshop though, so they'd have no need for table saws or routers! Pretty lethal in the hands of kids!

I can see me out growing this soon. A setup with more modern power tools would be great, but I'm not sure these exist......?

these are great for joints if you don't want to go down the full dovetail route and work with ply as well as sawn wood.

https://www.axminster.co.uk/ujk-technology-pocket-hole-jig-503726

they do a full kit including appropriate bits and screws. You cna make all the holes internally to the piece so they're not visible but they do plugs too.

Yeah, I have seen a few pocket hole jigs, and thought I would get one, nice to see a good metric one though.

What I would like to find is a decent floating mortice jig for a router, I can't believe that no one seems to make a simple alternative to the festool domino machine, which is silly expensive. They can be cut without a jig with a router, but I would like to make repeatable joins without messing up, and especially when just getting started a jig would be very nice.

Try cutting mortices with an actual mortice chisel.

Surprisingly fast and faff free and unlikely you'll get it wrong. And its properly satisfying.

"I would like to make repeatable joins without messing up, and especially when just getting started a jig would be very nice"

I appreciate that it's very satisfying to cut things by hand, but I also find it satisfying to make stuff that looks neat. Unfortunately, I'm too ham-fisted / impatient to do achieve that by hand.

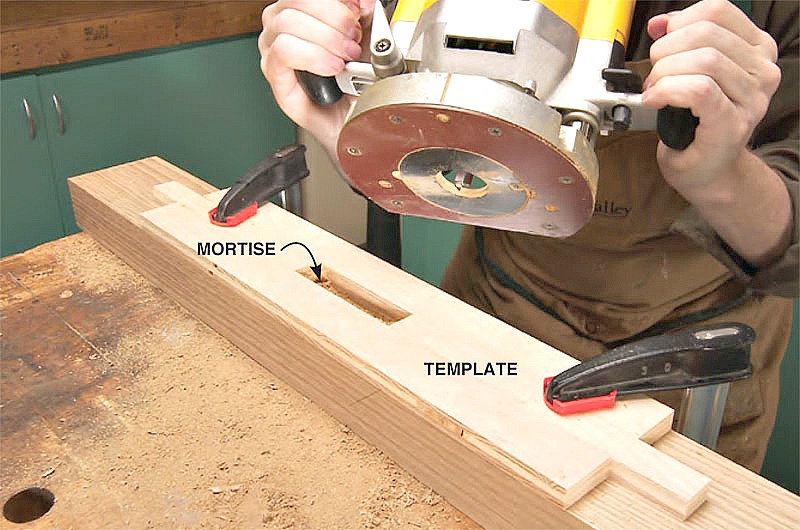

It's very easy to cut accurate, repeatable mortises with a router:

Fit a guide bush and make a template from thin ply (etc.) - only takes a few minutes to make any size, and only need to be done once.

Tenons can be cut on a router table (can be as simple as a sheet of ply on a workmate with a suitable recess for your router base... made using your router 🙂 ); using the depth stop on the sliding mitre saw; or with a similar router template and the stock clamped vertically to the side of your bench (don't be bamboozled by the designs for all singing, all dancing, fully adjustable tenon jigs unless that's what you want - it's very simple and quick to screw one together from a few bits of ply or MDF).

Most of my kit is Makita cordless, is the lxt plunge saw worth the cash over a budget titan?

I can't see the advantage of a cordless plunge saw - you're tethered to an extractor anyway and thats tethered to the mains - but you loose the ability to trigger the extractor when you start the saw. I think twin-battery tools have their problems too if you are sharing those batteries with other applications

So I wouldn't pay the extra over a budget saw for the cordless-ness. As a mains tool the makita and dewalt clones of the festool aren't really significantly cheaper than the real thing but without the benefits of Festool's long term backup and spares availability. But I think in cloning the festool they backed the wrong horse.

Mafell's much more expensive saw uses a much, much better rail than Festool, any of the mid range festool clones or the budget tools.

Mafell is crazy money but.... theres now a Bosch branded saw using Mafell's system (its effectively the same saw and rail made in the same factory) for a much more reasonable price. So if you are thinking of spending Makita money you should look at the Bosch GKT 55 - a little bit more expensive but in a totally different league

I am not sure whether to buy a plunge saw or circular saw in the first instance, the plunge saw looks more usable in general use, but a bench saw would be handy, and a circular saw could be used for that either via a wolfcraft 2500 or diy solution, and I am not sure a plunge saw would be suitable. I think that a circular saw that I could fit a dado stack to would be ideal and probably the most cost effective solution to the use I would get out of it.

I have been pricing up all kinds of table saws and mitre saws over the past week, and could easily spend a fortune, but the reality is I have quite a few furniture projects for the next 2 - 3 years, but after that a well equipped workshop is going to become largely redundant, I need to be realistic about what would be really good to have, and what would be an expensive white elephant.

I think that a circular saw that I could fit a dado stack

Avoid going down that route. Modern saws are designed to stop the blade quickly - the extra mass and momentum in a dado stack isn't that clever in that application unless its on a saw thats been specifically designed for them. In some instances its enough for the blades to unthread themselves and throw themselves around the room. If you're talking about putting a dado stack in a hand-held saw thats an awful lot of work for a small handheld motor to do - dedicated handheld groove-cutting saws cost upwards of a grand.

I suggested the little dual purpose mitre / table saws further up the thread. But a lot depends on application. Before getting into larger floor-standing machines the benchtop Dewalt DW745 table saw is blimmin ace - quick, accurate, repeatable adjustment, extracts well, easy to put away when you're not using it. I'd save money on the mitre saw (as in do away with a sliding one and just get well-made a non-slider) if you want to get table saw anyway as the extra options the sliding saw gives you (wider cuts, trenching cuts etc) can be covered by the table saw and a bit of jig making

I think also - maybe base your activity around the tool - rather than the furniture. You can look at a piece of furniture and there will be half a dozen tools and machines that would have been used in its production. But it you look at one tool - a table saw for instance - there are a whole hosts of processes you can do with that tool to cut, shape, joint, and detail material and you can devise and design perfectly good furniture just around those- theres really interesting things you can do with only that tool (for instance you you can turn a bowl on a table saw if you like)

So rather than equipping a full workshop to make a small amount of furniture buy just one or two tools and exhaust the possibuilitues with them before making further investments.

ok, that is good advice, I certainly don't fancy being sliced up with flying saw blades..

So I would probably be better forget using a circular saw as a table saw and getting a plunge saw first, or is there any advantage to a circular saw over a plunge saw? from what I can see a plunge saw is just a circular saw with some mechanical improvements so you can plunge it into a cut.

is there any advantage to a circular saw over a plunge saw?

not really. Regular circular saws are easier to use free-hand for rough, quick work. They have their benefits in a site situation but at a furniture scale a plunge saw is more geared towards the accuracy you need and is also cleaner to use indoors

I certainly don’t fancy being sliced up with flying saw blades..

it would certainly be the most entertaining obituary in the local paper that week

Especially if I started paranoid rumours that I believed ninjas were out to get me.

"from what I can see a plunge saw is just a circular saw with some mechanical improvements so you can plunge it into a cut."

Strictly speaking, yes, but I suspect that most references in this thread really refer to a track saw - a plunge saw with a guide rail. If you're doing any flat panel work they are really, really handy, and need much less space than a table saw. ("Cheap" ones in stock in Prestatyn Lidl if you're quick!).

Forget dado blades in the UK - I don't think you can even buy them - again, a router will cut channels / rebates.

A thicknesser is arguably more useful than a table saw - re-saw stock with whatever you have and clean it up with the thicknesser. Having uniform thickness stock makes everything much, much easier.

A thicknesser is arguably more useful than a table saw

useful at that job. I think you'd struggle to cut mitres, make finger joints, make mouldings and so on with a thicknesser 🙂

cut mitres - mitre saw

finger joints - router (but a table saw would be much quicker!)

mouldings - router again

😀

(Of course, it all depends on what the OP intends doing, how they like working, and how much space / money they have.)

I had considered a thicknesser combined jointer, although even the economy models are 300 quid. This is where it soon adds up, mitre saw would be nice, as well as table saw, some sort of shop vac dust collection system etc. I could easily spend a few grand before even making anything, which would be fine if it becomes a long term hobby but not until I really get going.

Can you get the lumber merchants to prepare wood through a jointer and thicknesser? I would kind of like to stick to hand (power) tools for at least a couple of projects, before deciding if this is really for me and investing in workshop kit.

I think my first project will be a bed (as that is what I currently need). But I would like to do a good job of it, I think power tool wise I should be able to do that with a router, orbital sander, plunge saw and a borrowed chop saw. Really it should be fairly simple, but I would like to use hardwood, and connect the main frame using tenons and mortices, with some kind of simple panelling for the headboard.

I make furniture part time as a part of my income. I'm not doing it all day every day, I'm self taught and I like to make a really good job of the work I do. As a result most of my business is repeat and referrals.

Most of what I make is melamine faced chipboard and vinyl covered mdf. But these materials can be of excellent quality and are used in bedrooms, kitchens, studys etc. costing many thousands of pounds. I can and do use oak and other stable woods.

Tools fall into 3 categories: those which are essential to do a job; those which help you do a job faster and those which help you do a job to a higher standard.

My basics are a Festool rail saw with a MFT top, resting on a couple of saw horses and a couple of pieces of CLS. With this I'm fine making accurate and clean cuts on boards up to 2800mm in length. With some bench dogs and a home made fence I can make angles and mitres so I don't need a chop saw, table saw, mitre saw and I'm able to work in somebody's kitchen or bedroom.

I recently invested about £800 in a Festool Domino setup. It seems a lot but it's taken my quality up a few notches and means that I can tackle jobs that I wouldn't have been able to do before. And that's important because I usually get called on because other firms can't do what the customer wants, like dealing with angles, corners, rebates etc.

However, stuff that isn't that critical or I don't use every day, I'm happy to use cheapies like Erbauer, Titan, Mac, JCB etc.etc. But never ever skimp on tape measures.

And I'm very pleased with my cheap Titan dust extractor with power take-off. Saved £300 over the Festool equivalent.

I’ve not really made any furniture except very ‘rustic’ outdoor benches and table, some fitted alcove shelves and a small simple bench for my children, but this thread is really wetting my appetite to make some freestanding interior pieces and basing my items on the relatively simple hand and power tools I have to hand.

I'm thinking of building some furniture, in oak, going to be joining the wood sections using a lap joint I think. Half lap at the corners and cross lap in the middles.

I have access to a chop saw that I think is height adjustable so I was thinking of using that to take out the majority of wood that I'd need to remove for the lap joints and then tidy it up using a rasp file? Does that sound sensible or is there a better way of doing it without having to purchase expensive tools.

Joints will be glued, and doweled at the corners for strength.

You can do it like that, but why not just use a hand saw and chisel?

The main reason is because I have the puny arms of a desk jockey. I'd be worried about taking too much off with a chisel, but it's a good suggestion, thanks.

Its ALOT easier to remove too much with a power tool than a chisel.

And you do not need big arms to tap a mallet against a chisel.

Which makes me sound all hand tooly again.

Big track saw and router fan.

Bigjohn sounds like you work in a similar fashion to Peter Millard on YouTube. Well worth checking out his channel everyone else to see how he uses a track saw and domino to quickly create smart furniture.

Big John - are you getting a domino 500 or 700? I can't decide. Biggest thing I'm likely to knock up is a bed or a door, which a 500 would be best for, but most of the time I'm working with 22mm thick redwood, which would suggest the 500. I see you can get an adaptor for the 700 so it'll take the smaller bits, but I wonder if it'll be too unweildy.

Don’t have any photos but I made some peices for a flat I had some years ago. (Money was...non existent). Bed, bedside tables, hall table & a few other bits & peices. Tool wise I had nothing electric apart from a drill. It was all pretty basic but it looked ok. I used dowel joints mostly.

Worth keeping your eye out for second hand Domino machines. I got the smaller version for about £200 and something from a bloke upgrading to the bigger one. I think the reason there isn't similar machines from other manufacturers is one of patent.

Modern chop saws are fantastic for the above trenching work. They have a flip-out depth stop for repeatable cuts to a given depth. The addition of some simple stops can give you very accurate and repeatable halving joints.

In terms of cordless versus corded tools. Cordless are now excellent. I have the twin battery Makita 36v plunge saw and wouldn't swap it for anything. The convenience of having no trailing cables is just fantastic. True, you have to switch your extraction on for the cut but....meh. Plus they actually do a Bluetooth receiver switch if it's that much of an issue.

For diy stuff with a lower budget though, I'd go corded. Be inventive(but careful) with how tools are used and you can get by with much fewer.

The Festool 500 will do up to 10mm dominoes with ease. I tend to use dominoes just one third of the thickness of the material so the 8mm should be fine for 22mm . Most of my stuff is 18mm so I get through a lot of 6mm dominoes.

Peter Millard's channel now checked out and subscribed. Looks like he has to lacquer all his pieces on completion whereas I usually work with materials which don't require finishing. However, lots of useful tips that may contribute to my continuous improvement. Or Kaizen, as they say in Nissan.

I spotted a lovely oak cupboard in the gift shop at Tate Modern the other week. Well within my capabilities and it had a price tag of £12,000. I don't know if my customer base would wear a tenfold price uplift, but food for thought.

How much do you pat for oak? say a 5cm x 15cm x 200cm plank

Looking around here, the cost of wood seems to be a lot more than the yanks pay.

Do you have any tips for sourcing decent wood without paying full retail?

is there a laymans version of the domino without the hefty price tag? surely someone must do a cheaper version? it looks like a biscuit jointer on steroids..

From what I can see no, other than marking up carefully and using a router with maybe a centring jig, which still wouldn't do everything a domino would. If makita/dewalt came out with one for around 200 I would buy one in a flash, or if I could get a second hand one as someone mentioned above. In the states festool could probably patent a "tool to cut holes for floating tenons" but I don't think that would fly for most of the rest of the world.

Do you have any tips for sourcing decent wood without paying full retail?

That’s why someone was talking about buying a planner/thicknesses earlier 🙂

the more processed timber is, the more it costs. Tree = cheap, sawn boards = money, planed boards = proper money.

But also, why oak? Look at ash, it’s blimmin lovely and a lot cheaper than silly oak. Why does everyone always want oak! Or chestnut, or English walnut, or cedar (technically softwood). Most of these are half the price of oak. Find a local sawmill. For the small furniture maker you need to find the offcuts department, some will be planed and ready to use. The rest will make you want to invest in a planer.

Where are you?

Mafell do a double dowel machine but it isn't as versatile as the Domino. It has a fixed separation between dowels so the joint is always 56mm wide - wider than a cupboard door frame. Festool has the ability to make both tight and loose mortices (very handy) allows for anywhere from 0 to 90 degrees bevels and is fantastically accurate even for fast repetitive work. Some joints you don't need either to mark or measure.

If you're looking for expensive - check out the Lamello Zeta biscuit jointer. Eyewateringly pricey (both machine and consumables and has a very limited range of uses.

Do you have any tips for sourcing decent wood without paying full retail?

One of the downsides of the middle-class enthusiasm for woodburners is smaller stockists of hardwood are finding it difficult to get reliable supplies - its so much easier for landowners / foresters etc to just chop or chip trees and flog them in bulk than take the time to select out and extract good wood for any other application.

Depending on the scale you work in some ways of acquiring nice timber can be:

Salvage it - find damaged or uninteresting furniture made out of good material and split it all up and make something new from it. Church Pews for instance - some salvage businesses sort of cut and shut then - shortening them to domestic scale and keeping the ends - so theres bits of straight board that come from the middle. But something like old dining tables, old office desks, school science desks etc would yield good wood. I've made stuff out of gorgeous iroko boards that were the benches and handrails from a 1960s school games changing room. Buildings of a certain age even the skirting boards would make good timber for furniture

For oak in particular look out for local suppliers of railway sleepers - some reclaimed sleepers are oak but are big and gnarly and difficult to work wit - however often they have a supply of new oak slabs in sleeper dimensions and in more manageable half thicknesses (about 2" thick) about the size and shape of a scaffold plank - for about a tenner. Not necessarily well seasoned and not selected, furniture grade - but oak non the less and a good size to rip up into the board sizes you would actually want.

If you can find a supply locally - whisky barrels are made of really good, straight grained, knot-free oak. "Barrel' staves are curved all the way round but 'cask' staves (which are actually much more common in the UK) are sort of boomerang shaped- a bend in the middle and two straight ends. The bigger the cask - especially the taller - the longer and more useful those straight sections of stave are. From a decent size barrel you can get a stack of short, chunky bit of straight oak (and have a smaller stack of curved bits for your fire 🙂 ) . You need to put a fair bit of work to then get them regularised and square, but its nice work as everything smells of whisky. Putting them through a thicknesser is heavenly - binbags of whisky pot pouri! But with a bit of jig making you can get them all squared up on either a bandsaw or a table saw

Another option is finding places that offer reclaimed wood flooring. I've just bought a couple of square m of maple planks that used to be the floor of a sports hall at Birmingham uni, cost about £35/sq (which is not a lot of floor but it can make a lot of furniture) . Again a bit of regularising involved to remove the tongue and groove, but really nice wood - the reclamation yard had all sort of woods there though. Given that their main market is in supplying room-fulls of matched material you can often do a bit of a deal on small quanities where they don't have a room-worth of material left.