![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

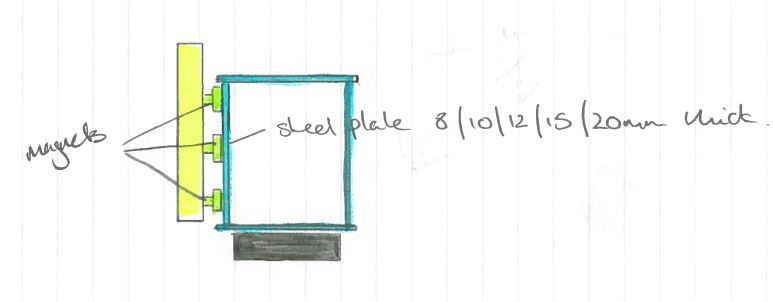

I'm trying to size the pulling force of magnets which will be used to straighten S355 J2N Steel plates, 8/10/12/15/20mm thick, prior to being tacked into position. There will be a series of 3 magnets across the height of the plate, height can vary from 900mm to 2500mm. Not even sure where to start...any help much appreciated!

Straighten 20mm plate with a magnet? A chuffin big one.

Start with a sketch?

yup, give us a sketch

Are your plates bent / distorted before you start doing whatever it is you are doing ?

If so then you probably want to put them through a set of plate rollers before you do anything.

As above a sketch , or a better description of what you are trying to achieve will help

Plates are distorted following welding steel angle stiffeners on back - rollers are not an option.

How much do you need to move the steel by? Do you need to just 'spring' it into position for tacking, or actually cause a permanent bend? If the latter, you'll have to bend it past where it needs to be, to allow for it springing back. Not easy. I do these kind of calcs for a living, but it wouldn't be a five minute job to work out.

EDIT Just seen the sketch. So you want to flatten the vertical green plate before welding it up into the box section? How big a magnet? As the poster above says - a chuffin' big one. It will depend on the dimensions and how far out of true it is. Suspect it will just spring back a little even after welding up into the box section. How long is it?

EDIT again. Those stiffener angles which have been welded on the back - they will probably make it even harder to straighten, as it's not just the plate thickness but the whole fab will need bending.

How much do you need to move the steel by? Do you need to just ‘spring’ it into position for tacking, or actually cause a permanent bend?

Not much - can be as little as 2mm to 10mm and it is just to spring it into position to tack weld top and bottom.

So you want to flatten the vertical green plate before welding it up into the box section?

Yes

How big a magnet? We have had some success with a chuck magnet but this is too large and heavy. Looking at maybe 300mm x 200mm dimension wise.

Suspect it will just spring back a little even after welding up into the box section. How long is it?

Up to 40m long - getting it to hold after tacking isnt an issue as the tacks can be enlarged and brought closer together.

Thansk for the help!

The pulling and holding force of a magnet, also depends on the thickness of the steel it is attached to.

It doesn't matter how big the magnet is, the magnetic force is limited by the amount of material it is magnetising.

Just thinking out loud, but you say the boxes are 900 to 2500 high, how wide are they ?

Are you using diaphragms inside the box across the width ? If yes, at what centres are they ?

Can you apply localised heat to the plates / angles to try to straighten out. When you welded the angles on , did you weld the plate down to anything ? From your description of the component parts, it sounds like you are making quite a structure .... bridge section ?

They can be up to 45m long. There is diaphragms at approx 2m centres. We want to move away from heat. I'd rather not go into further detail to be honest.

How do you intend to get the magnets off afterwards?

You asked for forces - I think that to determine the forces is fairly straight forward once the problem is understood - I think we have most of it.

A few questions ...

Which direction are the angle sections added... longitudinally down the 40 m length, or vertically in your diagram?

What size and spacing is on the angles?

Which direction is the curvature?

What format are you looking for your answer ? (excel / notes)

How do you intend to get the magnets off afterwards?

I'd assume electromagnets, I doubt any permanent magnet would develop enough force on (relatively) thin plates.

As someone above has said - a 900-2500 tall box 40m long is a very significant structure. Bridge, building? I'd talk to your designer ASAP, as just heaving the plates back to straight and tacking them up might lock in stress which hasn't been designed for and cause warping or other unforeseen effects.