![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

Is it possible to provide a drawing and have someone machine something up one-off? Is it expensive?

Orange used to do a shock mount for the Patriot to take a shorter shock, but I can't find one anywhere.

Yes and depends.

How much would you be willing to spend on it? Speaking to the likes of BETD would be a good start as they're public facing.

or porter_jamie (?) jamie porter off here. You'll find him in the "What was the last thing you made?" thread.

Even better if I could avoid doing a drawing and send in the original part and a sketch of what I want...

I'd want to spend as little as possible!

Whatever it is leave behind all concept of how much you might expect to pay for it as pre-exisiting batch/mass produced item.

edit

I'd want to spend as little as possible!

seeing that - you'll be needing to go down the mates rates route 😀

Should be relatively (? - obvs to what?) cheap, CNC is perfect for prototyping. As long as your design doesn't need some fancy 5 axis machine.

Expensive bit might be getting someone to do the CAD work, which doesn;t ahve to be the same place doing the machining.

If it's going to be a flat piece, it might be work looking at water jet cutting or laser cutting.

If it's going to be a flat piece, it might be work looking at water jet cutting or lazer cutting.

Yes, should have added that - I use Parker Steel for laser cut stuff for work - just sending them the dxf file. The price is stupidly variable depending on what other work they have on and if it can be nested with that.

spelling, convert? terrible! 😀lazer cutting

nice edit 😀

Not flat, no. Not complex either.

Laser/water cutting wouldn't work here I believe (from distant memory of the shuttle in question). Would need to be three seperate pieces then welded if it wasn't machined from solid

3 pieces could be simply bonded or bolted too. Hmm.

Any pics of the part?

Around my way most places charge by the hour.

No need for an electronic drawing if it's a fairly simple part, it could be quickly programmed on the machine.

You could make that from sheet with a drill and some washers?

How come all you IT desk jockeys think all machining begins and ends with CNC. Many straight forward one off pieces are still better/more efficiently produced by a manual machining process.

Best Regards

The Grumpy ex Toolmaker

£60 per hr is about top rate on 5x, most company's would charge around an hr to machine that and an hr to program plus the cost of mat'l £140 would be fair for a 1 off like that.

With a 5x you could make a part like that complete in 1 setup. Quick simple and spot on first time.

Not so grumpy 5axis NC programmer 😉

I used to use three old blokes in a machine shop hidden behind some terraced houses, no sign or anything. One of those places you only find out about by word of mouth.

The place was filled with old machines and they seemed pretty busy every time I stopped by. I had them make a load of brake caliper brackets for cars and modify some discs. I provided the technical drawing for them and they knocked them all out in less than a week around their other jobs.

I'd expect to pay £75-100 for something like that done by hand if its a one off, depending on complexity and material, it looks like a slightly odd shape.

If its [url=

this[/url] it would just be a matter of cutting a piece of stock of the correct thickness to shape and drilling some holes. No need for CNC for a one off.

Edit - metal cutting bandsaw and a drill press would be sufficient IMO.

Looks like something you could do with a drill and a saw 🙂

Have you tried Orange for a drawing or to see if they have one in a box somewhere (perhaps in a filing cabinet)

But for that, piece of bar, drill some holes (more holes = lighter 🙂 )then drill and cut the slot for the shock, not really seeing much need for any fancy machining. tricky bit would be getting the measurements for how far down the shock needs mounting but with enough holes in the frame mount you should be able to tune to your hearts content.

You could probably knock up a prototype in wood to check your angles out.

Yes

You really need a spoon or other cutlery 😉

<dumb post not reading the thread properly>

skiboy - Member

£60 per hr is about top rate on 5x

your obviously not in Aberdeen then?

Buy offcut of material from metal wholesaler on ebay.

Cut to size with a hacksaw, drill holes in the right places

then run it through with a router/dremel/hand-file to fit.

Easy.

Have you asked orange?

I asked Orange but got no response. Might try again.

I could cut it and file it to shape myself I suppose. No idea what kind of alloy to use or where to get it tho.

aerospace grade. thats what everyone uses....

7000 series probably for strength.

[url= http://www.ebay.co.uk/itm/ALUMINIUM-PLATE-190mm-x-145mm-x-4-1-2-114mm-offcut-HIGH-SPECIFICATION-7050-/111311775164?pt=UK_BOI_Metalworking_Milling_Welding_Metalworking_Supplies_ET&hash=item19eab2e5bc ]here you go[/url]

H30 plate.

Thickness is an issue. I won't be able to reduce the thickness by hand much so it has to be bang on. Also, any kind of heat treating required?

molgrips, are you anywhere near essex? you can come along to the unit and sort one out if you want

i'd make it out of 6082 (he30) or 7075 if i happened to have a bit laying around. hours work probably. you might want to cnc the radius on the end if you wanted it to look nice but it would be quicker to do it on the manual. your only issue is if there is a specific diameter hole for the shock bolt - if its a stupid imperial size then you are into buying a drill, or interpolating the hole on the cnc, which is no drama really

Kind offer mate thanks, I'm in London during the week so it depends where in Essex I guess 🙂 Would have to be early evening tho.

Just thinking, I may be able to achieve what I want by sliding the original mount back further. I want to lower the COG of the bike but still avoid bottoming out. Basically make it like an Alpine 160 🙂

the unit is in laindon i am there most evenings. have you had your injections....

Half hour train journey - nice one.. I'll have a mess around with the bike, see how it looks. I could bring the original part and given the shock dimensions in the manual we should be able to figure it out.

ok, im off for a week soon over easter, give me a shout when you have the bit and you can nip over one evening. email in profile

i saw an alpine 160 this morning at epping. it looks fairly straight forwards tbh. i hope the hardware holding it on is not standard. this one had shitty bolts and god awful zinc plated nylocs holding it on.

I'll find the manual with the pictures of the two parts in it. The one I have is a black anodised single piece but I think it is nyloc-ed in.

Might wait until I have reassembled the bike and see if Ican use the existing mount slid back. The reason for using a shorter shock after all is to lower the bike a bit.

molgrips - Member

Even better if I could avoid doing a drawing and send in the original part and a sketch of what I want...

I'd want to spend as little as possible!

Contact Orange surely they can have one made up for you, by the

people whom made there ones for them.

the one on the alpine looked like a 45 quid job to me, probably 90/100 quid if you wanted it to look pretty with cnc's chamfers all over the place and anodised and so on

also, could you re drill the holes on the standard one?

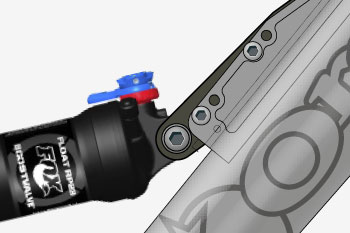

Ok so I got the forks sorted out, reassembled the bike and started looking at the shock. Here's the part:

Given that my overall aim is to lower the bike overall, it turns out that I can do this with the existing shock mount. If I slide it down one set of holes there's loads of clearance at maximum compression. If I leave it like it is in the picture then the tyre tickles the seat-tube at max compression.

Looks pretty decent like this, with the forks at 160mm:

PS not sure if you can see those images...

I cant see pics

Dammit, missed edit window

[url= https://farm6.staticflickr.com/5481/14073844880_a95531c50b_c.jp g" target="_blank">https://farm6.staticflickr.com/5481/14073844880_a95531c50b_c.jp g"/> [/img][/url][url= https://flic.kr/p/nrE8KW ]WP_20140524_005[/url] by [url= https://www.flickr.com/people/11569254@N06/ ]molgrips[/url], on Flickr

[url= https://farm4.staticflickr.com/3767/14073892547_465885e9be_c.jp g" target="_blank">https://farm4.staticflickr.com/3767/14073892547_465885e9be_c.jp g"/> [/img][/url][url= https://flic.kr/p/nrEnVM ]WP_20140524_001[/url] by [url= https://www.flickr.com/people/11569254@N06/ ]molgrips[/url], on Flickr

Have you placed a ferrule between the new plates to prevent the fin plates compressing together?

Looks good btw!

I should say, that's the original plate not a new one. Conclusion is that I didn't need a new one for my purposes.