![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

Yeah Mike, I need some inspiration for doing bits on my van!

never seen this thread before, but by god i've just wasted the last hour and a bit reading it... good work sir.

MOAR!!!!

Amazing stuff.

Hope you are getting away in the sunny summer!

Have you got a link to the ebay seller of the solar panels?

Cheers!

Suggestion for rear shelf (shelves) if not too late. see 3 weeks ago instalment:

Go for a double shelve but size it using Ikea or similar plastic storage boxes. You'll get 4 or 5 decent ones in that gap with timber supports. They'll be easier for sorting stuff and it wont fly about quite as much.

You win at vans! (Still proud of my mini version though) 😀

Love these threads, top work oh and Sazters mini van is ace too. I've got my eyes out now looking for a suitable donor!

You must be back from your hols by now! 🙂

Yeah Mike, where's the update? If you don't post something soon, I'll have to do something on my van and you don't want that (because people will see how rubbish mine is compared with yours).

Bump!

We need more pics and an update!

An amazing thread, I'll never do this but still very inspired...any updates?

Wow. Shes a monster! (in a brilliant way). Looks like you could handle a trip to outer mongolia in five star luxury.

FWIW, we have a Ducato at work, and while the body work is ruined due to it having a very hard life at the hands of neanderthals, the engine (2.5L i think)(is tight as a drum and the underside is in great condition.

Hmm, inspiring enough to make me go and find another job on our ongoing T5...

Chapeau! Mike.

Blimey, I've neglected this -- my profound apologies. Imagine a wibbly-wobbly back-in-time effect and we end up here, fitting a mains hookup:

I'm not wild about it being right up against that bodywork seam, but it's actually inside a pillar on the other side and there's basically no scope for it to be anywhere other than where it is. Inside the cable heads up the wall and ends up here:

I hardly need to point out that the wiring isn't finished in this picture 😉 From there cables head out to various locations, including the water heater at the back, a connection for a charger under the seats and a couple of sockets:

The single space next to the socket is for a 12V socket, which is made from a normal cigar lighter socket mounted in a standard blanking plate:

At this stage there was a whole load of exposed wiring (and bodywork and insulation) between the ply panel around the front window and the front washroom wall. So I made this bit:

Which goes here:

Propex control top left, water heater gas control top right, water heater mains switch bottom right -- those are the nasty brown controls that came with the (second-hand) water heater, I'll be changing them for nicer ones in The Fullness Of Time (which is pretty damn full). The overall effect is something like this:

The space above the panelling will all be taken up by overhead locker, eventually. In a bid to hide some more bare insulation before our summer holiday, I started making a ceiling:

It's 3mm ply, which is light and bendy and follows the curve of the roof nicely. Lights are recessed LEDs. Another bit further back:

Not forgetting to route lighting wires first:

Not looking bad:

A final piece over the rear bunks:

And while I was at it, lining the walls -- this was an arse of a job because we'd put the bed frames in and then put walls up so the frames wouldn't come out in one piece, so I had to dismantle them and then put them back together in situ:

Once it's filled/sanded/painted it'll be pretty tidy. On the subject of tidy, a couple of little tidying jobs -- finish off the edge of the floor at the sliding door:

Line the gap between the toilet cassette hatch and the actual toilet:

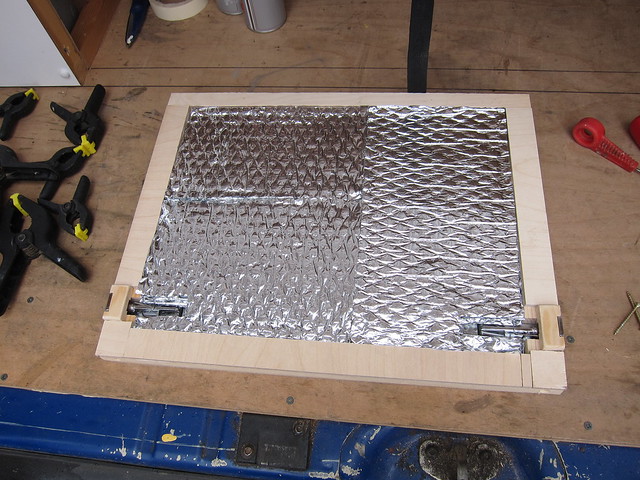

Rebuilt the temporary framework in the rear washroom wall and stuck some insulation in it mainly because there was some lying around (but it also stops the hollow wall sounding hollow):

And line out with PVC/ply stuff:

Line the outside wall and make a start on framing for the inside wall and door frame:

And that'll probably do for this update. More soon, there's a bit of a backlog 😉

Have you got a link to the ebay seller of the solar panels?

Go for a double shelve but size it using Ikea or similar plastic storage boxes.

Good plan. It's now double shelved but in a kind of "make it so the bikes go in" way and spacing them at what they end up as. With any luck we'll find some boxes that'll fit 😉

Postscript: Trip to Lakes wholly successful, and even managed to sort the minor smoking issue that we had -- the van had been belching black smoke under power for a bit, but having hoofed it up a couple of Lakeland passes it magically cleared 😉

Up to this point the boot/garage space was distinctly unfinished, being all exposed timber and insulation. Got around to sorting that, first by lining the doors:

(the little round holes are to access the stay releases so you can open the doors 180 degrees) and then lining the rest of the space:

It's a bit jigsawish because we were using up offcuts from the washroom -- the stuff comes in 8x4 sheets which isn't really a very convenient number for the inside of a van. We'll be covering the joins with some PVC strip eventually. Redid the shelf as two shelves as discussed:

The vertical bits are temporary, I'll be making a ply panel with access holes in it to go there. We made the useful discovery that if you take one pedal off then three bikes will go on the bottom layer, which is potentially handy.

Made a couple of shelves to go over the foot end of the bunks for the kids to keep books/toys/etc:

4mm ply base and front with a 15x12 batten to join them (underneath the front edge), supported on more 15x12 batten on the sides of the van. Seems stiff enough:

And put in a surround to cover the front door pillars where the bulkhead used to be:

Looks fantastic - thanks for the Solar panel link - they look very reasonably priced.

Liking the wipe-clean boot very much.

They were the cheapest panels I could find from a UK supplier, they've been fine so far. We're using 2 x 100W ones.

Boot space needs some sort of suitable flooring, not quite worked out what to do there yet 🙂

Nice thread.

Checkerplate is the obvious answer, but it's not particularly cheap (if I go for aluminium) and I'm not entirely sure if I like it or not. On the other hand, it's the boot floor, I probably don't have to like it 😉

Don't do checkerplate with that pattern! I've got it in my brazing shed, and it is awful to sweep clean - the ridges at 90 degrees to each other just trap sweepings (i.e. sweep in one direction and half the ridges collect the dirt, sweep in the other and the opposite ridges collect the dirt). The aluminium will also be unkind to the bottom of fork legs and will leave black marks unless anodised.

I'd use heavy duty industrial vinyl (like bus / wet room flooring). Google Polyflor etc. A 1m x 2m strip was something like £50 when I last bought some. It isn't cushioned so forks won't rip it.

Awesome thread, just wasted over an hour reading it.

Awesome thread, just wasted over an hour reading it.

Me too!!

wasted!!!?

Time well spent, I'd say

I'd use heavy duty industrial vinyl (like bus / wet room flooring). Google Polyflor etc. A 1m x 2m strip was something like £50 when I last bought some. It isn't cushioned so forks won't rip it.

Sounds good. I'll look into it 🙂

How big is the boot floor? I have a strip of heavy duty 'coin' moulded vinyl flooring left over from doing the back of my T5...

The main part is just under 1.9m across and about 0.5m deep, but I need to do the part under the bunks as well which is something like 1m x 0.7m. Ish 🙂

I'll have a look n the shed later and see how much I have...

Chapeau, Mike!

This has got to be one of the best threads in ages, looking forward to seeing more. Glad you're finding time to actually use the van too!

Beginning to slightly lose track of what got done when now, but no matter. PLOUGH ON. Here's the (unfinished) overhead locker for the kitchen, which, helpfully, my Dad made while I was faffing about with other bits:

In the interests of lightness, the doors are hollow -- what you see there are 12mm ply frames, which then got skinned with 3mm ply to give this:

So the whole kitchen now looks like:

You'll have to imagine away the pots of glue, boxes of screws and random tools.

While parents were helping out, father-in-law made a backrest for the bench seat:

And MiL upholstered it:

It's made the seat way more comfy for relaxing in. The backrest is supported by a couple of short lengths of webbing attached to the B pillars -- when driving it sits vertically, when parked up we can just roll the cab seats forward a bit and let it tip back to a comfy angle. We've sacrificed the ability to easily climb through from the cab but we were mostly walking round to the sliding door anyway. If it's really chucking it down it's still possible to scramble over, just not terribly dignified 😉

At this stage the interior was almost looking vaguely finished, if you don't count the lack of washroom door (or indeed washbasin) and various other details:

So then we went on holiday, which was ace:

(really must paint up those wheels...)

Although there was a minor hiccup on the way home:

Which resulted in us having to leave the van at a French Fiat dealer while we came home in a (very small) hire car:

That's me trying to work out where the gear lever is.

It took the best part of a month for the van to rejoin us in the UK, but only a couple of days for a local garage to fix it. Water had got into the injector loom and made the ECU most unhappy, with properly torrential rain in France being the final straw. Fortunately the ECU survived (despite what the French garage initially said) and the repair was considerably less financially painful that we'd been fearing. Coming up in a future instalment: Sorting out Fiat's woeful efforts at drainage 🙂

Ace!

(apart from the breakdown obviously).

I've often wondered about keeping DIY interiors lightweight.

I'm not a fan of all these composite materials they use in modern caravans/campers, but thin ply over a frame sounds good.

I do need to weigh it at some point 😉 I'm hoping we'll have at least 500kg of payload, which would mean an unladen weight of 3t. IIRC the empty van was (on paper) just under 2.2t, giving 800kg for the conversion. Which sounds a lot, but then the batteries alone are nearly 50 kg, the rear seats are 30-odd, the LPG tank is 20 I think... It mounts up.

I bet the kids love it.

If you don't mind me asking, where is the campsite with the mountains / cliffs in the background? Can't decide if it looks like Switzerland.

This. Is. Awesome.

Mike, you win! Keep the updates coming.Please. Bobbing around the North Atlantic waiting on weather & this thread has just helped me pass a good hour or so.

But left me feeling woefully inadequate.

Chappeau sir.

Is the campsite in Le Bourg d'Oisans?

It's wonderful work sir. I'm fighting a battle with the wife. She (unreasonably) wants me to finish the house before we start on another project.

My bet on the holiday pics is somewhere between Grenoble and Chambray.

Well if we're betting on the photo, I'm going to (probably be completely wrong) and say Camping Jungfrau at Lauterbrunnen, Switzerland. Guess assisted by what might be a 2014 Swiss Vignette in the windscreen.

Camping Jungfrau it is -- well spotted 🙂

wingnuts: Our house has plenty of missing skirting boards and unpainted bits 😉

This is awesome, you're doing a great job! I spent Saturday at the camping and caravan show at the NEC as I've been toying with building something similar for a while now, but you're fit, finish and attention to detail knock a awful lot of what I saw into a cocked hat!

I was hoping to build into a sprinter LWB hi-top to enable a moto x style garage under a double, but I like the idea's you've given me with your 4 berth arrangement as I'll need to transport and sleep four as well. I've done the usual scouring of the internet but this is one of the best how-to threads I've seen.

Thanks for the inspiration, and good luck for the rest of the build.

😀

I'm rather pleased with that guess - especially as it was 1995 when we stayed there (but been back to the area plenty of times since). Top tip with kids if you travel down there again, you can avoid some toll motorways in Germany and break the journey at Speyer where there is a fabulous technical museum with its own secure campervan area. Museum unlike any other I've seen - Jumbo Jet on stilts that they can climb around with a huge stainless steel tube slide, Buran Space Shuttle, Russian Submarine, Antonov cargo plane (all open to clamber around). Also a sister museum at Sinsheim with Concorde and Tupolev Concordski.

http://www.technik-museum.de/en

Fabulous job on the camper and the write up has been a highlight of many lunchtimes - is there a date when you will class it as "finished"?

Love it, turning out really well 🙂

My current van is on its second incarnation, still not 'finished' after owning it for around six! Next years plan is to tidy it up ready to sell, there's no rush as the van that ticks all the boxes has only just been released and I need to wait at least two years for the eye watering £25-30,000 plus VAT price tag to become affordable.

I reckon a used one will be under £10k within a couple of years as thankfully they depreciate really really fast!

P.S For the boot floor, how about that heavy duty rubber stud moulded flooring? I plan to use it throughout the van next time as I've had various floor coverings which have turned out to be dirt magnets or susceptible to ripping.

Great thread....

Are you keeping a tally of hours spent/costs etc.

Whatever the figures, I'm sure it'll be a great investment.

Bravo - great stuff, Mike.

jwt: Went to that show last year, it's a good opportunity to pick up ideas. We made a couple of changes based on what we saw there, although mainly to avoid things we didn't like in pro vans -- originally the fridge was going to be on the floor, but having looked at a few we decided that we didn't want to be grovelling in a narrow aisle to get things out of it.

We did think of getting an extra-high van and putting in a drop-down bed at the front, but the vans were too expensive. Maybe next time 😉

mick_r: Good tip, thanks -- looks ace 🙂 We went through France on this occasion, I've got relatives near Dijon so we did a stopover there. Definitely planning to do Switzerland again, though...

As for finished, I suspect they're never really finished. If we can get the rest of the interior in and painted by the first anniversary of getting the van (ie middle of December) I'll be pretty happy.

spooky: That looks ANGRY. Have they changed much beyond the front? Dimpled rubbery stuff is on the shortlist for a boot floor.

rockhopper70: There's a massive pile of receipts that we'll pluck up the courage to add up one day. Kind of lost track of hours, beyond "a lot". I reckon we're looking at £12-13k (including the base van) by the time it's done. I don't think DIYing is in any way a profit-making exercise, but if and when we sell it I'm hoping the net cost of ownership will become very reasonable. The plan is to get a good few years use out of it 🙂

Way better than Grand Designs this. Thank you Mike.

Mike_D - Member

if and when we sell it

Dibs!

Mike, the blurb reckons its 80% new components, but how that's measured...

+1 point for a new indicator stalk, -1 point for the original ladder chassis? Who knows, but I bet its measured in their favour!

Anyway, its largely new, has some very powerful engines and still pulls 3.5 tons which is the critical bit for me, but the main advantages is the wheelbase is now longer with less overhang so should be more stable and safer for towing and give less grounding issues, and you can get a locking rear diff. Just need to tweak my layout as the ideal wheelbase/body length combo for towing is 50cm shorter than my current mwb van.

I too have a couple of box files stuffed with receipts, the conversion came to more than the £5k cost of the van...

Been away in Autumn/Winter Mike?

Learning anything about the build, now that it's getting used?

Crikey, I've neglected this thread. Where was I? /reads back.

Oh yes, the saga of the flooding engine bay. Investigations (based largely around tipping buckets of water down the windscreen) revealed that a healthy proportion of rainwater would end up here:

That's a bracket hanging off the middle of the scuttle that holds some sort of actuator that's something to do with the EGR valve. Yeah, showing off my MAD MECHANICAL KNOWLEDGE there. The water coming off there ends up on top of the engine and is trapped by the shape of the head. Genius. But not as good as where most of the rest of the water goes:

That's the nearside of the engine bay. Look down a bit at where that stream's ending up:

It's aimed with unerring accuracy straight at the plastic cover over the connector between the main wiring loom and the ECU. Hmph.

There's a plastic cover over the scuttle at the bottom of the screen, which I took off for a closer look. I guess there's a semblance of a seal in there. OK, no, there isn't:

The cover's also in two pieces, overlapped in the wrong direction so that water attempting to run off along the designed-in slope towards the offside tends to go through the gap instead -- that's where the dribble onto the top of the engine is from. Much Sikaflexage later and the cover was sealed to its other half, sealed to the windscreen on the back and for good measure, sealed along the top edge too:

Next order of business was to get rid of the water that should now be gathering in the scuttle cover. As I said, it's supposed to run off to the offside and through a drain hole, but there's only a hole on one side, the slope isn't that substantial and if the van's not dead level (like, for instance, parked on the camber on the left of a road, as if that could ever happen...) the water just sits there.

Fortuitously, there's a blanking plug stuck in a handy-looking hole on the nearside, so I took that out:

Drilled the hole out a bit bigger:

And gooped in a usefully-sized spigot tube thing I found in the plumbing box (it's actually an insert that you push into PVC pip before using push-fit connectors):

More rummaging in boxes of left-over tat revealed a handy length of corrugated pipe, which got gooped and ziptied onto the pipe insert thusly:

It's routed down through the engine bay to exit by the front wheel, pretty much mirroring how the standard drain on the other side works:

Yeah. FACTORY. Kinda.

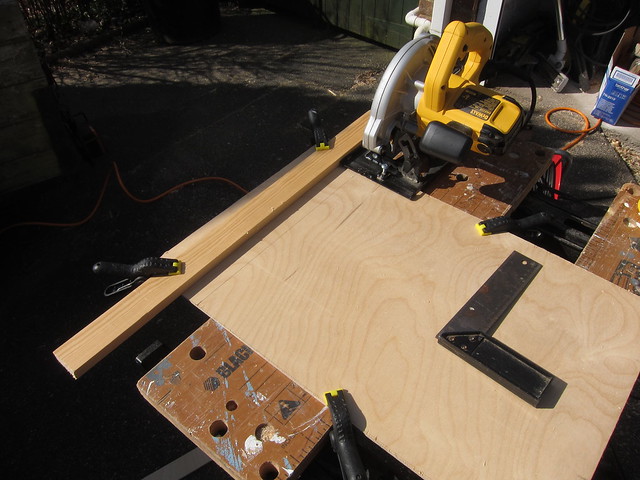

Buoyed by this achievement, I tackled a little "tidying" job. The table top still had square corners and was a bit wide to boot, so I attacked it with a circular saw to narrow it a bit and then rounded the corners with a router. Those of a delicate tool-use sensibility may wish to look away:

That's the router fence with the plate reversed and inverted, a couple of blocks of wood glued together and a random bolt stuffed into a blind hole on the back of the table top to rotate around. Surprisingly, it kept the alignment pretty well:

Repeat on the other corner, put the leg back on:

Much better, especially for moving into the back part of the van which was a bit of a squeeze between table and kitchen before. The table still needs a load of weight taking out of it, it weighs as much as a small child at the moment.

In amongst all this we returned to France at October half-term -- we were meant to go to Disneyland in the summer but the breakdown scuppered that, so we'd promised the kids we'd go back. Did it on the (relative) cheap by taking food with us and camping in the car park. Which turns out to be quite a popular option:

It actually worked really well -- parking's included with the annual passes we bought, it's really close to the entrance so we went in first thing, came out at lunchtime when it got busy, had a meal, chilled out for a bit and went back later in the afternoon when it was quieter again. Beats overpriced hotels and crappy grub 🙂

Oh, and long-time followers will have noticed that we didn't manage to get the interior finished and painted within a year -- we've now had the van for 13 months. We did manage 33 nights away in it in 2014, though, which seems like a result to me 🙂

Boom its back, YES!! Love this thread.. Whats next???

Probably finishing the washroom -- put in shower tray, finish lining the inside, add lighting, basin, cupboard. Will mean dropping the waste tank to add another inlet. Also still need a lot of drawers and cupboard fronts making for the rest of the interior. And another overhead locker. And lining the space over the cab. And lining the sliding door. Boxing in under the travel seats. Tidying wiring. Control panel for lights and level gauges and stuff. MANY THINGS 🙂

We did manage 33 nights away in it in 2014, though, which seems like a result to me

Definitely - congratulations!

Probably finishing the washroom -- put in shower tray, finish lining the inside, add lighting, basin, cupboard. Will mean dropping the waste tank to add another inlet. Also still need a lot of drawers and cupboard fronts making for the rest of the interior. And another overhead locker. And lining the space over the cab. And lining the sliding door. Boxing in under the travel seats. Tidying wiring. Control panel for lights and level gauges and stuff. MANY THINGS

Blimey - makes my shed seem very simple indeed.

That's just the stuff I can remember 😉 There's a new incentive in that we want to get rid of our tatty conservatory, which is currently employed as a storeroom for van bits and sheets of plywood...

I don't ever want this thread to end

I sort of hope it will eventually 😉

.....

??? 😉

Found this thread. I am Speachless.

If I find a Speach I'll be sure to pass it on 😉

So after something of an over-winter hiatus, we're back on it 🙂

First up, the washroom rooflight sprung a leak. Which was annoying. The only way to be sure of sorting it was to pull the whole lot out and start again:

Seems to have worked.

After that, we looked at tidying up the shelf over the cab a bit. Thus far it's all been exposed insulation and a slightly manky plastic shelf. Made some cardboard templates:

Transferred to a handy plywood offcut that was about the right size:

Cut out and stuck in:

They're Sikaflexed to blocks stuck to the van roof, and to the side of the plastic luggage shelf. Once they were set, Mrs D spent an afternoon getting dizzy on spray glue and lined the whole lot with magic stretchy carpet:

At some point there'll be another ply panel as a face to the whole thing, we'll come back to that...

Made a start on an access hatch to go under the bottom bunk. At the moment there's just a hole to the boot space. Put some new uprights in the appropriate places, chopped out the batten that ran across the floor:

Put in a timber moulding to cover the edge of the floor -- this'll come out and go back in again once we've put some flooring in the boot.

Started to make a door, but thus far it's just two bits of wood so not really very interesting. Moved on to lining the sliding door, which I keep forgetting hasn't been done:

I've made a reveal around the window as per the other side of the van -- the panel will be further in than the face of the window, so something needs to bridge the gap. Also boshed in a couple of rivnuts for an extra handle to make the door easier to shut from the inside. It's big and heavy and not that easy to fully close:

After much measuring, marking, faffing and cutting:

Had to do it in two pieces, because the door's 95mm wider than a standard sheet of plywood. Although it works better on that orientation anyway because the ply's bendier on that axis and fits the curve of the door. The window aperture was marked out as close as I dared but left a few mm extra all round and will plane/sand it down flush later.

At this stage the bottom of the door still looked like this:

Oh yes. Homely. More cardboard, more plywood:

Fitting the lower panel was challenging, because with the door shut the front half is obscured by the bench seat. And with it open it's outside the van. I ended up Sikaflexing half the door with it half open and the other half with it shut, then half opening it again to slide the panel in and holding it with one hand while boshing in a couple of temporary self-tappers to keep it all in place while the glue goes off. End result:

Marvellous. The join between the two sheets will be filled and sanded, and there'll also be a padded panel across there which will hide it.

Love this conversion - just killed an hour of my night shift reading it, so thanks for the distraction!

Out of interest, where did you buy the long-ruler-spirit-level-with-handle thing?

You're welcome 🙂

Big level was borrowed from my Dad, he got it from a local hardware shop I think. It's suffered a bit during this job and doesn't have a handle any more. Or a level. So really it's just a giant ruler now. Still v useful. Must find a replacement...

Expect one or two more updates shortly - heading to the Alps at Easter so keen to add a few things first. We're not staying in it (except a night on the way down and a couple more at Disney on the way back), so I don't need to worry about tank insulation or anything. Thankfully...

Extra update 'cos I found some stuff I'd not posted..

Ages ago I started making a slide-out support for part of the bed. The smaller hinged flap needs supporting at the end of the kitchen, and there needs to be an extending piece to come out into the aisle to hold up one end of the large flap. My first pass used crappy runners, so step one was to take it all apart again and use some better runners that actually hold it straight:

I'm not sure now why I decided to make the fixed part of the support sit outboard of the sliding part. Maybe because I just want to make things unnecessarily difficult? Here's the fixed part before fitting:

It's held on by the ply closing panel at one side and by the timber stub at the other, which goes through the slot in the sliding piece. The finished thing looks like this when closed:

Opens like this:

And the bed flaps rest on it like so (just one shown here, I was standing in the way of the other one):

I had to do a bit of trimming and notching of the large flap so it cleared various corners and seatbelt brackets and could actually extend far enough to reach the support. While I was at it I drilled a bunch of holes in it:

This is mainly in the interests of getting some air circulating under the mattress, but it also saved about 400g in weight. Pretty trivial in the context of a 3,500kg van, but that's a couple of extra bottles of beer we can carry 😉

The fully-deployed bed platform now looks like this:

Pretty pleased with that 🙂

Very nice work mister. Looks really neat!

This really is the thread that keeps on giving, fantastic work.

I'm getting back to work on our van this morning thanks to your thread!

Superb skills mike D. That bed support is the work of someone with way too much time on their hands. 😀

Keep em coming..

Excellent! - what width have you managed to get on that bed?

🙂

There's this as well -- MiL has been busy and made a cab curtain. We wanted it completely out of the way when driving, so it's held up by [s]neodymiumyum[/s] [s]neodiumyymy[/s] powerful magnets stitched into pockets at the top and some steel washers self-tappered into a handy bit of trim:

It does go all the way to the side, it was mid-putting-up in the picture...

Alex: Bed is 130cm wide, so 7cm narrower than a standard double. It's substantially wider than the rock'n'roll bed in our previous van 🙂

🙂 great work!

That's one hell of a conversion you've done.

(it's about time I sorted a bed out for the back of my T4!)

UPDATE. We have a big boot space under the lower bunk, which was just open to the main accommodation. To stop stuff ending up in the wrong place (and to reduce draughts), I made a hatch. Frame:

(here clamped to a bit of thick ply to keep it straight while the glue dries)

Cut out a piece of thin ply to glue to the frame:

Needed something to keep it shut, and after a bit of deliberation went for flush bolts, usually used on one half of French doors. Looks quite sleek:

Filled with insulation:

And in place, having glued a piece of the PVC-coated ply onto the back:

As it looks from inside the boot:

I drilled an extra hole so that one of the bolts can be used to hold the hatch open when needed:

While I was rummaging around in the aisle, I remembered that this bit really needs some proper drawers eventually, although actually the temporary bodge works pretty well 🙂

In other news, we drove to the Alps to go skiing. Didn't actually stay in it in resort, because the water tanks aren't insulated and bad things would happen in consistent sub-zero temps. We did a night in an aire on the way down, one in Bourg St Maurice after our cheeky seventh day on the slopes, the inevitable couple of nights in the Disney car park and another aire night closer to Calais. It snowed a surprising amount for Easter:

1,700 mile round trip, didn't break down, happy with that 🙂

Brilliant, as always 🙂

Too kind. I think of it more as "persistent" 😉

HI Mike

do you have a good online source for those nice fold-flat hinges on the bed and the french door bolts etc? Oh, and the runners you used on the slidy out bits too. Need some similar for my project

Cheers

Mark

The hinges are counterflap hinges, mine came from Screwfix:

(always found that the tricky thing with hinges is knowing what all the different sorts are called...)

Bolts were Screwfix too:

I'll have to look back to find where the runners came from, will get back to you on those 🙂

Damn, didn't even realise Screwfix did stuff like that. Brilliant as we have a branch in my local town. Might change out those hinges for the silly piano hinge I have used so far. And those bolts look great for what I want.

Cheers Mike

Mark

Kudos to you!

Keep the updates coming (I only really posted so it was easily available in forum activity!)

Some more to come, just want to finish off a couple of bits 🙂