![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

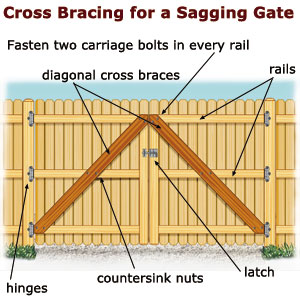

Our neighbour, a single Mum with 3 kids and no DIY skills, has two heavy hardwood gates, T&G plank panelled, which are sagging under their own weight and no longer square. Each gate is about 5' wide so the leverage is considerable. The timbers are not very tight together and they seem to have been assembled mostly with wood dowels. I think the only way to get them square again is to lift up the outside edges to slightly above square then screw a diagonal timber from the top of the hinges to the bottom outer corner, which will brace them and might even pull them back together.

Any other suggestions? I don't want to disassemble the gates completely.

That would be a brace in compression rather than my way, which is in tension. Why would that be better?

Edit - no different mechanically I guess and it does get around the problem of the latches at the bottoms of both gates.

[i]Why would that be better? [/i]

No idea, tbh, it's just the way they're always made. I think it's far more effective at preventing exactly the sag you're trying to correct.

Think bracing sounds the only option bar taking them all apart, although perhaps bracing with an 'X' rather than just a / would add a bit more stability?

Wow, this forum is better than DIYnot.com!

Carriage bolts are an even better solution than long screws.

I guess by bracing like that you are stabilising the top rail which is preferential.

back to the 'why that way' - it's all down to how the forces in parallelograms work - putting the brace the other way has no effect on stopping the outer edge collapse towards the ground under it's own weight. Doing it the way suggested transfers the weight to the bottom hinge.

back to the 'why that way' - it's all down to how the forces in parallelograms work - putting the brace the other way has no effect on stopping the outer edge collapse towards the ground under it's own weight. Doing it the way suggested transfers the weight to the bottom hinge.

Surely it does? A triangle is a triangle. Bracing the 'wrong' way stabilises the bottom beam from the top hinge, which in tun stabilises the top by nature of the vertical running up from it. Only difference is the cross piece will be in tension rather than compression so, presumably, more likely to fail due to the wood splitting.

I think.

In mechanical terms the effect is exactly the same, you are adding a solid diagonal to brace a flexible paralellogram. One way has the diagonal brace in tension and the other in compression. The advice on here is to do it in compression and since that avoids the latches at the bottom outer corners, that's the way I shall do it. I plan to close the gates, lift them to slightly above horizontal, drive wedges between them so as to compress them back towards the hinges then bolt on the cross braces with carriage bolts in tight-fitting holes drilled right through.

I might also reinforce the corner joints with some exterior ply screwed on.

Someone on DIYnot.com has suggested adding jockey wheels, which I will consider, but actually the gates close up to a slight slope so can only be supported when closed.

Someone has suggested using steel cable to do it in tension (obviously) if you've got any of that kicking about.

I quite like the idea 😀

'turnbuckle gate repair' is what you need for the cable solution - allows you to wind the cable tension up to get it exactly right.

The brace should be in compression if relying on bearing contact between brace ends and rails, as per the top photo. With the brace in tension the joint would just open up. The brace ends should really be cut to form a square, to have bearing contact with the vertical stiles as well. In practice the gate will sag a bit this way as the timber pieces all shrink across the grain.

If retro fitting a brace to the face of the rails with screws or bolts, the force transfer is via the fixings, so the brace will work either way, in tension or compression, and is less vulnerable to shrinkage effects.

I've done it (with a much lighter gate) using gardening wire and it worked well. Two screws at the corners suggested and the write fixed to them under tension (eg flex the gate up, tighten and then let it take up the slack/tension.

A diagonal brace is traditionally in compression, probably because it's more suited to a simple wooden joint that way

If you go for a diagonal in compression you might need to over-compensate and make the latch side slightly higher as the new wood may shrink with time

If you can be bothered a rod with threaded ends and nuts and washers drilled horizontally through both stiles and the brace will pull the gate together, or an external cable as has been suggested