![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

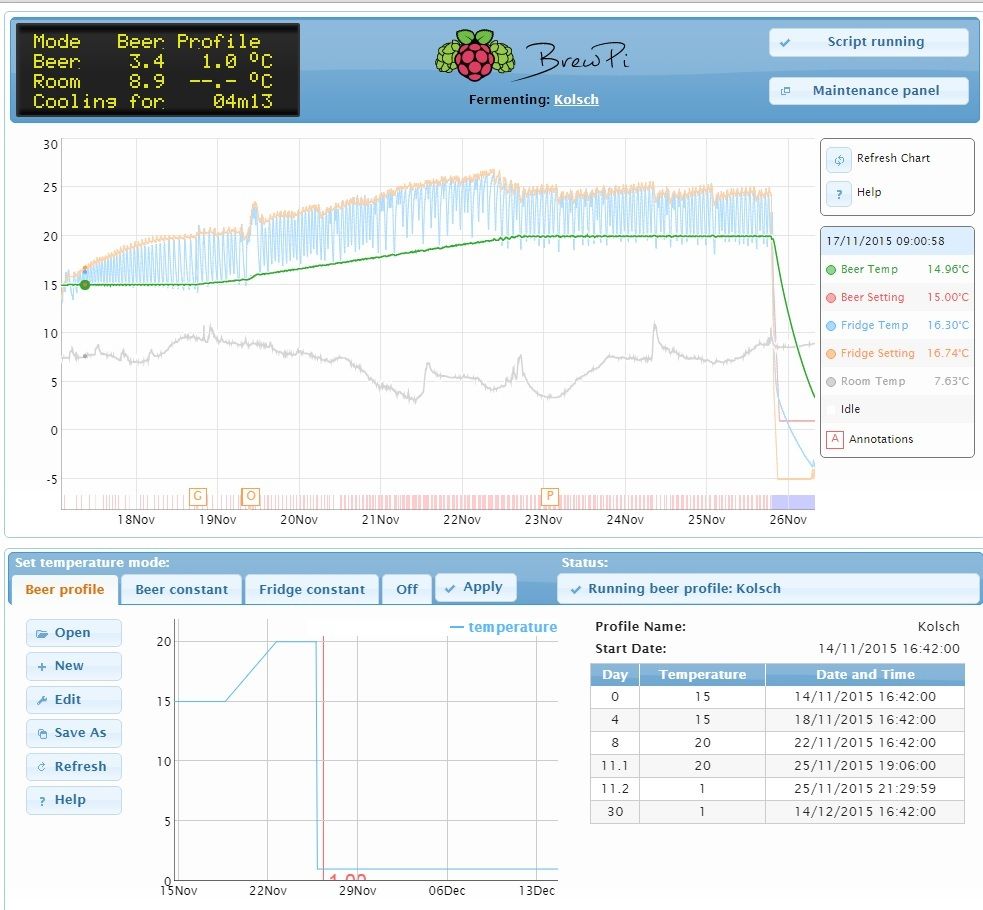

For the beer/DIY geeks...I've attached a screenshot of my home made Brewpi.

Basically, my fermenting fridge is not at my house, so being able to monitor and control it remotely was a bit of a challenge.

I put together a brewpi, which lets me monitor temps and control both the heating and cooling elements in the fridge. I had to remove the internal thermostat in the fridge to allow for crash cooling.

I also hooked up a webcam so that I can check krausen etc. I originally tried to get a webcam working with an IR LED array, but it just wasn't working at all. So instead I bought a regular LED USB light and hacked the cable, sticking in a relay and hooking it up to the pins on the Pi. I then wrote a bit of script that turns the light on, takes a photo, then turns the light back off. Works well!

Beer temp is measured through a thermowell, so is the actual temp of the fermenting beer. I can keep the beer within 0.1 degree. The fridge has it's own sensor to let the PID do its thing, then I installed a third sensor to keep track of temp in the outhouse, mainly to make sure the 60w heater I have in there will be sufficient as winter approaches.

It's all completely automatic now, I don't lift a finger other than to adjust the profile.

I originally had it hooked up to a mifi device, but it wasn't very reliable, so I'm not poaching my mum's internet connection through a couple of powerlines and it has been faultless.

🙂

Now that is geeky!

*appluads* As someone who escalated from 10ltrs to 1600 I applaud your escalation of tech !

That is legend!!! Want,

Can you do me one, I'm currently looking for a fridge...

Clobber, cost wise you'd be looking at:

Raspberrypi = £20

Arduino Uno = £10

Relay board = £5

4.7k resistor = £0.01

DS18B20 sensors (min 2) =£8 total

Thermowell = £10

Wifi dongle = £10 (subtract if you can use ethernet)

Total = £63

I'll assume you have a spare SD card, power supply and a couple of USB cables, along with a couple of sockets and wire (I used old extension cables).

A 60w greenhouse heater will set you back about £10. If you want to add a webcam and light for taking photos, add another £7 total. You might want to add a case for the pi etc, but I just use tupperware tubs.

So you're looking at about £60 for full automation and/or control of your fermentation. Not bad!

I'd consider doing another, but flat out at work at the moment. In all honesty though, you'd enjoy doing it yourself. I'd never done any of the stuff needed to put it together, but with only a couple of head scratching moments I managed to get it done in an evening.

Excellent guide [url= http://www.homebrewtalk.com/showthread.php?t=466106 ]here[/url].

OK, thanks for the links PF

Would one of those pi zero 's be good for this pf?

I'm not sure. I used the old style Pi (i.e. not a Pi 2) and it runs perfectly.

Interesting how different people escalate in completely different ways.

I'm planning a cut price (eBay/China) version of the electric brewery which with upgraded relays would happily run a comercial brewery. Everything pumped, controlled etc. Then connecting it upto some 6 gallon PP buckets. Why? Because Im a process engineer and like the idea of dumping in a few kg's of grain at one end and not touching it untill beer comes out the other 😀

TINAS, you could be in luck...there's a guy on ebay at the moment who is trying to sell an aborted build of the panel (he bought all the parts but didn't put it together). I wouldn't be surprised if he would take an offer, it's be relisted a couple of times.

[url= http://www.ebay.co.uk/itm/Electric-Brewery-Control-Panel-KIT-240V-UK-electrics-parts-for-home-brew-REDUCED-/262129069517?hash=item3d081c2dcd:g:XYwAAOSw4HVWE9UU ]Linky[/url]

Tempting, although his price is over double what I'd budgeted. Although he has used a lot of probably better quality bits than i'd been intending to. Might need to sit down with a spreadsheet and do some maths.

Antique geekiness on the topic of forced carbonation.

http://onlinelibrary.wiley.com/doi/10.1002/j.2050-0416.1925.tb04942.x/pdf

Summary for anyone struggling with long sentences:

Forced carbing is fine, and if done cleanly with a carbonation stone (they're experimenting with assorted pipes wrapped in cloth, but ultimately it's the same apparatus) produces a very stable beer, very quickly. It also covers the advantage Peterfile mentioned, that it works well not just for carbonation but for eliminating contact between fermented beer and air.

But it doesn't mimic secondary fermentation. Unfiltered, or secondary fermented beer is better in every way apart from clarity, but they accept this won't work commercially as people have grown up to expect completely clear beer.

The exception is in particularly dry styles where forced carbonation gives a dryer palette (or rather it's natural carbonation, or brewery gas that imparts a fuller/sweeter flavor).

On a homebrew level, you tend not to filter anyway, so it's entirely possible to achieve the same benefits of conditioning when you transfer to the keg.

I've got a saison currently conditioning at room temp in the keg, which I'll then drop to about 1 degree when it's ready, fine it and then force carb it. So perfectly conditioned, perfectly carbed and perfectly clear!

Raffle here for a home brew setup

http://www.jimsbeerkit.co.uk/forum/viewtopic.php?f=6&t=74000

only a fiver a pop

Thought Saisons were supposed to be a little cloudy ?

They are, but this one has been brewed for someone and they wanted it clear! No telling some people 🙂

Gelatin is fab for when you're planning on handing the beer out since there's no sediment or haze (other than occasional chill haze), so it tends to get better reactions for regular beer drinkers who, as TINAS says, seem to think clarity means a better beer.

I've got a saison currently conditioning at room temp in the keg, which I'll then drop to about 1 degree when it's ready, fine it and then force carb it. So perfectly conditioned, perfectly carbed and perfectly clear!

When you say conditioning in the keg, do you mean you've transferred from primary to a keg (with some yeast still in suspension), added sugar for a secondary, and now you're going to clear it and transfer it to a 'clean' keg (or bottles)?

It's worth having a read at the end of Section of of Chris White's "Yeast" if you can get your hands on it (great book), specifically the sections on bottle conditioning and cask conditioning.

For bottle conditioning, the benefit is cited as the scavenging of oxygen (a problem for small scale breweries and home brewers). Disadvantages are results that vary, sediment, potential autolytic destruction of yeast cells releasing unpleasant flavours.

Secondary fermentation/bottle conditioning generally does not contribute any flavour, it simply adds co2.

For cask conditioning things are slightly different. When talking about casks, the term conditioning does not mean the same as condition. In this sense conditioning means the maturation process (rather than just the addition of co2).

I transfer from primary to the keg without filtering, so plenty of yeast still in suspension. I then leave to "mature" at whatever temp suits the yeast/beer (i.e. my focus here is allowing the beer to develop rather than carbonate). Some beers don't benefit from any maturation (e.g. a pale ale), but something like a robust porter does well sitting at cellar temps for a couple of months. I prefer to do it in the keg rather than a fermenter because I it's less oxygen permeable, easier to store and move around and I can immediately hook up to carb and serve.

When I'm happy that the beer has reached peak flavour, I crash cool and fine with gelatin in the same keg. Then the first pint I pull is filled with all the gloopy yeast and sediment that the gelatin has dropped out. After that it's all good 🙂

Ahh now I understand.

I think I'm going to need a bigger circle of beer drinking friends and more kegs!

You'd be amazed at how quickly your beer goes once people (colleagues, friends, neighbour) hear that you're handing out free beer!

It's the same effort to brew 2 litre or 20 litres and the cost difference isn't much, so I prefer brewing more and giving more away.

My drinking has stayed pretty much the same throughout my brewing adventures...usually zero through the week and then 8 beers spread between Friday to Sunday. So I've got a lot to give away!

The irish place I get my kegs from does them super cheap whenever they get a container in. Works out at around £27 a keg including delivery.

PF, Group buy on kegs from your Irish Place?

Thehomebrewstore.ie were doing them for £90 for 3 plus postage if that's where you mean?The irish place I get my kegs from does them super cheap whenever they get a container in. Works out at around £27 a keg including delivery.

We probably have a half with dinner most evenings and a couple of pints at the weekend.

My only worry with kegs is keeping lines clean etc. Fine in the summer for BBQ's etc, not so useful if the lines need cleaning every other pint over the winter. Have you tried those taps that mount onto the disconnect? I presume you could pour a pint from any keg and then have a keg of star-san to flush out the tap afterwards.

PF, Group buy on kegs from your Irish Place?

It's easier just buying separately, since their postage is actually surprisingly cheap (much cheaper than it would cost to bring in loads and then send them out to each other here).

Thehomebrewstore.ie were doing them for £90 for 3 plus postage if that's where you mean?

That's the one. I preordered and got them for 33 euro each I think?

My only worry with kegs is keeping lines clean etc. Fine in the summer for BBQ's etc, not so useful if the lines need cleaning every other pint over the winter. Have you tried those taps that mount onto the disconnect? I presume you could pour a pint from any keg and then have a keg of star-san to flush out the tap afterwards.

I had the same concerns. The way I've dealt with it for now is easy...I don't actually drink any beer "on-site", so have to take it all away with me, so taps were a bit pointless.

Instead, I've got a cobra/picnic tap attached to beerline and a disconnect. I simply fill up bottles from that to take away with me. A beergun is on the xmas list. I purge the growler of o2 first.

When I'm done filling from one keg, I put the disconnect on a keg I keep full of starsan and give it a squirt (as you mentioned), which cleans out all the previous beer, then I just move on to the next keg and fill.

Looks good scaled.

I'd definitely go for a thermowell. It also means if you need to move the carboy you can just pull out the probe.

I would suggest getting longer probes if you want to have your pi/arduino anywhere other than right beside the the fridge.

Also, pick up some jumper cables. I've got some spare if you want me to send over a few.

Are you connecting via ethernet? If you want to use wifi you'll need a dongle.

Once you've got the basics set up, let me know and I'll direct you to some other scripts which are really handy (like auto reboot when connection lost etc). I'm not sure how computer literate you are, but you'll probably want to set up dynamic dns to ensure you can always get to the webserver (quick and free, but requires an additional script on the pi and a bit of setting up)

Any problems or queries, give me a shout. It's quite straight forward, but not without challenges. In particular, you'll need to work out the colour coding on your probe...they're all different! Google is your friend here.

Oh, also...are you planning on connecting a socket to the relay and then just plugging the fridge into that? If so, rip out the thermostat on the fridge and bypass it completely by connecting the wires that previously went through the stat. 2 minute job, but absolutely essential if you want to cold crash or lager (which is one of the best bits of having a dedicated fermenting fridge with full control!)

Yeah, i was going to have the heater and the compressor running off the relay so i can cold crash before bottling, my crappy little bucket with a tap in the fridge, do all the fermenting, cold crash (with gelatin from the sounds of it!) then bottle up once it's done and do secondary in the bottle.

It's a double fridge/freezer, i don't see why with therm controlled heating/cooling the freezer section shouldn't work as well, the algorithm should just learn to blast the cold for a shorter length of time. For starters i'll probably just bang another heater in there and use that for some wine.

For me the Pi bit will probably be the easiest, compared to the shite that i have to work with all day...

UI[9]=A problem caused the application to stop working correctly. Windows will notify you if a solution is available.

UI[10]=&Close

FriendlyEventName=Stopped working

double fridge/freezer, i don't see why with therm controlled heating/cooling the freezer section shouldn't work as well, the algorithm should just learn to blast the cold for a shorter length of time

Not sure how this would work? Am I missing something?

The cooling circuit and compressor is common. So when the fridge temperature is above your setpoint it will kick the compressor in.

Unless you intend to just run the freezer at a lower temperature and have the main fridge take priority?

I think it'll depend on the way the cooling is configured, i'll have a good look at the weekend.

I know that there's a fan in both the fridge and the freezer so i'm hoping that it's an evap unit with two independent cooling circuits off a common compressor. I know that's how Mille do it, but i'm not going to butcher one of those 😛

If not then i'll have to have two heating chambers and a manual (cold) crash override

Does anyone have advice on corking wine bottles? I tried using a twin lever corker, straight uncoated corks (grade 2 apparently), but they will not go all the way in, regardless of the pressure applied. Corks were tried both soaked in sanitising solution and dry, it made no difference - about 1/4 of the cork would remain out of the bottle.

I see that you can buy coated corks - do they go in easier?

A rather ignominious first post on the brewing thread 🙁

Brewed up a gallon of IPA today, my second ever batch. Mashed in OK, mashed out OK, Sparge fine, did the boil, added the hops, put the brew pot in ice bath to cool and when I went to check the temperature, noticed weird reading. Then noticed that this was because the thermometer had broken. It had broken before I put it into the brew, so hardly any contamination - maybe one small drop of red dye on the surface. Filtering it into the demijohn seems to have removed it.

2 questions:

1. worth carrying on, or bin the lot? I can't smell it off the mix that is in the demijohn (see below).

2. Answer to 1 may depend what it was. It was a food thermometer, but I'm unsure what the fluid is (or was..). I don't think it was ethanol as it floated in top of the water and had a slight smell, reminiscent of paraffin.

So advice please. Many thanks 🙂

Probably fine, it's not mercury.

Amazed you could smell it over an IPA TBH, not enough hops!

I have a good nose (I'm a chemist) so could pick up the odour in the kitchen after it broke, despite the hops. Definitely not ethanol (and I knew it wasn't mercury! 😉 ) Other option was paraffin, which I was wild about drinking but its such a tiny amount and I think its probably trapped in the filtrate that I've gone ahead.

Will play it safe and let Mrs M try it first when it comes round to drinking 😆

Drink it. You will be fine. IANAC but you are.....

My cousins a circus act (and a stuntman), so he get's to gargle paraffin for a living, and he's not dead yet, although it's only a matter of time.

Thanks for the feedback guys. Will report back in due course on palatability (or otherwise)

Well, my brewing has been coming along nicely.

Got the Grainfather to brew in, built a temperature controlled fermentation chamber with a chest freezer and a STC-1000 controller and got some cornie kegs powered by some old fire extinguishers.

Easy to keep the beer cool: [img]  ?oh=682460c2303cda62d59f487f36d049ad&oe=5736C203[/img]

?oh=682460c2303cda62d59f487f36d049ad&oe=5736C203[/img]

Also got Mikkeller's beer book which has some great recipes in it.

Currently have a keg of Monk's Brew (to which I added some Carafa III for more roast flavours) on the go. 19 litres of 10% dark Belgian ale - dangerous times!

have some Czech pilsner lagering in the freezer at the moment, should be ready just in time for me and the boys' annual Easter MTB piss up weekend in Dumfries

Free afternoon, discovered the local off licence sells home brew supplies, so dug out my kit from the loft, dusted off the removal van detritus, plumbed together all the bits that had been sat in a box for way too long and bought some of everything that the shop had (not much choice)!

Recipe:

1campden tablet

1 tsp gypsum

(no idea what our water is like, but it's Thames water, so it'll knock your teeth out if you look at it's pint - hard)

3kg Youngs Pale malt

500g Youngs Crystal malt

30g Fuggles at 60min (First wort)

20g Goldings at 60 min (first wort)

10g goldings at 15min

10g goldings at 0min (steep, cool and whirlpool).

2 sachets of Youngs ale yeast.

Recipe is based on the Landlord clone, but adapted for what was available, and it'll be a bit weaker. Which is fine by me, the fridge is full of 7% porters and IPA's, I could do with something a bit more drinkable!

Shout out if you spot me doing something wrong or you think the recipe is going to end up undrinkable!

[url= https://farm2.staticflickr.com/1528/25634411980_0b4c8dc304_k.jp g" target="_blank">https://farm2.staticflickr.com/1528/25634411980_0b4c8dc304_k.jp g"/> [/img][/url][url= https://flic.kr/p/F4e4Am ]2016-03-20_03-47-36[/url] by [url= https://www.flickr.com/photos/7614571@N05/ ]thisisnotaspoon[/url], on Flickr

Do as I say, not as I do! You wouldn't think I work in health and safety would you?

[url= https://farm2.staticflickr.com/1552/25840030151_c607185c92_k.jp g" target="_blank">https://farm2.staticflickr.com/1552/25840030151_c607185c92_k.jp g"/> [/img][/url][url= https://flic.kr/p/FnoUHe ]2016-03-20_03-42-46[/url] by [url= https://www.flickr.com/photos/7614571@N05/ ]thisisnotaspoon[/url], on Flickr

He did the mash....

He did the [s]monster[/s] mash [i]at 66.5C[/i]

Missed it my 2C, so added another litre (making 10.5 in total) of boiled water.

[url= https://farm2.staticflickr.com/1525/25635564420_0c3aeb11c6_b.jp g" target="_blank">https://farm2.staticflickr.com/1525/25635564420_0c3aeb11c6_b.jp g"/> [/img][/url][url= https://flic.kr/p/F4jYb1 ]2016-03-20_04-34-31[/url] by [url= https://www.flickr.com/photos/7614571@N05/ ]thisisnotaspoon[/url], on Flickr

[url= https://farm2.staticflickr.com/1541/25635573250_3fe880b7fa_b.jp g" target="_blank">https://farm2.staticflickr.com/1541/25635573250_3fe880b7fa_b.jp g"/> [/img][/url][url= https://flic.kr/p/F4k1Nf ]2016-03-20_04-34-52[/url] by [url= https://www.flickr.com/photos/7614571@N05/ ]thisisnotaspoon[/url], on Flickr

It will definitely be a bit weaker! Though that may not be a bad thing!

A lot of crystal in that, might overpower everything else.

I'll just deduct it from the sparge.

Brewsmith is saying 3.7% if I make 20l into the fermenter, which is about right, I want something that can be drunk on a school night rather than the fridge full of 7% porters and IPA's I have at the moment 8)

Mash done, turns out my tun needs more insulation, dropped to about 58C 🙁

Now mashing out at 76C

And built a cooler 8)

[url= https://farm2.staticflickr.com/1713/25304946674_d0936ec3ed_b.jp g" target="_blank">https://farm2.staticflickr.com/1713/25304946674_d0936ec3ed_b.jp g"/> [/img][/url][url= https://flic.kr/p/Ey7t33 ]2016-03-20_05-34-45[/url] by [url= https://www.flickr.com/photos/7614571@N05/ ]thisisnotaspoon[/url], on Flickr

Will tidy up the plumbing at some point, had intended to just bend the ends over and jubilie clip hose on, but they kept kinking so some brasswork was needed. Really a 10mm right angle to 1/2" BSP female fitting, and a 1/2" to barb is all that's needed, but that's not what was in the toolbox.

Hmmm, bit too efficient. Over 90% (fly sparged, probably a little slowly). Currently sat with way too much volume and still at 1.037 where it should be 1.033.

Fingers crossed it doesn't boil over.

Compensating with a bit more hops at the end to balance out the extra strength and maltyness.

Started using a Corny keg for fermentation. I only make 10L batches so plenty headspace for krauzen. Probably the "cleanest" beer I've made - ie no off flavours etc. Problem now is that I think another one would be great so I can keg! Expensive habit.

Also stopped sparging and just doing a top up before the boil. 50% efficiency but I don't really care too much. Saves the mess of sparging BIAB.

Brewing up an "Old Ale" like a Theakstons Old Peculier this weekend. Yum yum.

Moving house soon and the new place already has a fridge - queue brewfridge conversion!!

What are folks brewing these days? Any new techniques or kit?

Father forgive me, it has been 10 months since my last brew 🙁

Holy thread resurrection!

Made my first all grain brew the other week. A Smash golden ale using S-04 yeast, East Kent goldings and maris otter pale malt. BIAB using a 32 litre pot, I ended up with about 16 litres into the bottle. It mostly went well, except for the following:

1. It was a bugger to get cool. I don't have a chiller so used trugs of cold water, which worked to an extent, but I need to speed up the process due to Life. Or I could try no chill and pitch the next day. Thoughts?

2. I batch primed from the fermenter into a pressure barrel with the sugar added in solution. The barrel leaked at the tap gasket. PTFE tape and Vaseline?

3. Bottling is a pain. I ran them through the dishwasher on its hottest setting, then soaked them in cleaner/sanitiser, then rinsed in clean water before returning them to the dishwasher rack to drain. I was thinking of buying a bottle tree and some Starsan to speed the process up.

1. It was a bugger to get cool. I don't have a chiller so used trugs of cold water, which worked to an extent, but I need to speed up the process due to Life. Or I could try no chill and pitch the next day. Thoughts?

2. I batch primed from the fermenter into a pressure barrel with the sugar added in solution. The barrel leaked at the tap gasket. PTFE tape and Vaseline?

3. Bottling is a pain. I ran them through the dishwasher on its hottest setting, then soaked them in cleaner/sanitiser, then rinsed in clean water before returning them to the dishwasher rack to drain. I was thinking of buying a bottle tree and some Starsan to speed the process up.

1) if i didn't have a chiller I'd no-chill. At the worst you end up with slightly opaque beer, which you may be able to cure with a proper cold crash later on. But plenty of people manage to make it work just fine.

2) New tap, the ones most fermenters come with are a often a bit crap but if you look on the-home-brew-shop.co.uk the more expensive ones don't leak and last longer.

3) Yes, although you can just clean with oxyclean (generic stain remover powder from poundlan/lidl etc as long as it's not scented), that will loosen off any gunk in the bottles, then just rinse with starsan and a bottle rinser. No need to drain the starsan bubbles.

Thanks TINAS. Might invest in a cube and give no-chill a crack. If anyone here has tried it I'd be interested in how you got on with it, and if you made any changes to your hop schedule.

Holy thread resurrection!

My SMaSH golden ale turned out pretty well in the end: a bit too bitter but a nice hop aroma, and it improved considerably after being left a month to condition.

I've since made a Landlord clone from the Graham Wheeler recipe, and it's a cracker. This time I left it to cool overnight before pitching, and invested in a bottle rinser and some starsan. Much easier!

Have you lot all given up?!

I have a saison fermenting at 30 degrees right now. It smells extremely promising.

Brewed a green hop beer last Saturday using freshly picked hops, just finished fermenting.

I haven't brewed all year.

I have ordered a load of ingredients and will be starting a few batches in teh next couple of weeks.

They are all grain recipe kits, can't be bothered with Beersmith and bulk grains at the moment.

I just started a brewing and distilling masters this year.

So in celebration today is brewday.

Pale malt, columbus hops for bittering and nelson sauvin for aroma and Califonia ale yeast

Something nice and simple. Going back to basics and making sure I get everything spot on - temperatures, gravities etc

Have also got the brew shop up the road ordering in a dome and condensor to turn my grainfather into a distillery and a brew bucket stainless steel conical fermenter.

Just finished a brew morning. Nothing fancy, Festival New Zealand Pilsner.

Have you lot all given up?!

Sadly, yes. Last few batches went horrible so I assume my plate chiller is contaminated, and at £90 a pop I'm not likely to be buying another one soon.

Although I do have a grain kit ready to do if I can find the time

[quote=john_drummer ]Have you lot all given up?!

Sadly, yes. Last few batches went horrible so I assume my plate chiller is contaminated, and at £90 a pop I'm not likely to be buying another one soon.

Although I do have a grain kit ready to do if I can find the time

I have a copper immersion chiller I don't use any more.

£25 posted to you?

I've got one of those in the [s]shed[/s] brewhouse somewhere, but thanks for the offer

Afternoon all,

I'm looking to get a brew on the go next week however am looking for some recipe advice.

It has been a while since i last brewed and was looking to follow the recipe provided with the 10L massive brewery kit which for me was 2.5kg of maris otter paired with magnum hops as asimple way of getting back into it.

Unfortunately my recipe says add 12.5g hops at start of the boil then "the rest at 5 minutes from the end" and i did not take a weight of the second bundle of hops when i made my first batch. From memory the bundle of hops was about 2-3 times the size of the initial hops but i would appreciate if anyone know what an accurate figure may be.

I'm guessing the Magnum hops have an AA% of about 15?

If so, then 12g will be giving you quite a bitter ale. About 40 IBU, which is about what Punk IPA comes out at. 36g at 5 mins would knock that up quite a bit, to about 60.

Is that you are looking for? Was the first batch very bitter?

How much weight of hops do you have? It might be worth keeping some for 0 min addition and then some for dry hopping afterwards. Especially with just the pale malt, all the flavour will be coming from the late addition hops.

[url= https://www.brewersfriend.com/ibu-calculator/ ]https://www.brewersfriend.com/ibu-calculator/[/url]

You don't get much bittering acids when added at end of boil. Utilisation percentage drops. I wouldn't really include the 5 mins additions in your bittering calcs

Sadly, yes. Last few batches went horrible so I assume my plate chiller is contaminated, and at £90 a pop I'm not likely to be buying another one soon.

Stick it in the oven (remove any plastic fittings first), nothing survives above 100C. There will always be crud inside it which could harbour bacteria but if it get's hot it's sterile. That and pump the hot wort through it for 15 minutes at the end of the boil (with no cooling water), again nothing survives 100C.

Whenever I get infections it's always either the fermenter, kegs or bottles (or associated racking equipment) because it shouldn't be possible to get an infection in the kettle or cooler. If you want to rule out steps in the process, do a forced fermentation with some wort in a thoroughly sterilised bottle, if it ferments (assuming you took the sample before adding yeast), the pH changes, or it tastes rank after a few weeks in a warm place then you have an infection.

The other useful test is a forced fermentation, put a disproportionately high amount of yeast in a bottle and add wort, ferment for 48 hours in a warm place and measure the gravity. This should match the FG of the rest of the beer. Now you can monitor the beer over time and know if it drops further you have an infection rather than just being too quick to bottle it.

You don't get much bittering acids when added at end of boil. Utilisation percentage drops. I wouldn't really include the 5 mins additions in your bittering calcs

Mathematically it doesn't, but most people find it tastes bitter. The formulas work best with 'normal' beers, when you're adding 3x as much at flame out as for bittering in an IPA it's a bit outside the range they were developed for!

Also bear in mind it will keep isomerisation until cooled, so it's really 5 minutes + however long it's steeped/whirlpooled for, all that stops with the boiling is stripping off DMS and aroma.

Oven for plate chiller sounds like a plan, cheers.

I have a kit to put on,if I do that & it goes ok then i’ll Know my fermenter is ok

Here is an example IBU calculation, working backwards from a designated target bitterness and pre-selected amount of aroma hops, with additions at 0 and 48 mins in a 60 minute boil. You can look up the utilisations in tinseth tables.

Hop additions

Time Variety %Alpha %Utilisation Amount

0 Admiral 14.3 35 37.8g

48 Tettnang 5.1 15 210g

Hop calculations

1 BU = 1 mg/l isomerised alpha acid (iso-aa) Total isomerised alpha acid (iso-aa) required to give 25 BU in 140 litres = 25 x 140 = 3500 mg

Iso-aa from late addition:

iso-aa from Tettnang = 210 x 5.1/100 x 15/100 = 1.61g

iso-aa required from Admiral = 3.5 – 1.61 = 1.89 g

Admiral required = 1.89 x 100/14.3 x 100/35 = 37.8 g

You can see the huge extra amount of hops you need to add at the end to get a similar amount of bitterness/alpha acids....

At the end of the day, you should just look at 3 hop additions:

Start of boil = bitterness.... variety isn't hugely important. Pick what is cheap and has high alpha acid, so it keeps things cheap.

Other 2 are end of boil and dry hops. They give the aromas. Variety is important here, and a blend works well.

ummm . . you going to look into co - humulone ratios , or keep that vital bit of info to yourself?Start of boil = bitterness.... variety isn't hugely important. Pick what is cheap and has high alpha acid, so it keeps things cheap.

Thanks for the replies all, the magnum hops I have, have an Alpha Acid of 9.8%. I have 100g so more than I need for this batch. Hopefully enough for 2 or 3 so I can figure out my technique and control over the process.

I wan to be able to produce a simple single malt single hops beer consistently before moving on to mor complex brews.

So plugging some numbers into the IBU calculator based on Aa of 9.8 if I add 12.5g at 60 mins from end then 25g at 10 mins from the end I should end up with an IBU of 30 - 35 depending on my target original gravity.

Not quite sure what my original gravity should be but vaguely recall 1.065 from my last brew but could be off with that.

I wan to be able to produce a simple single malt single hops beer consistently before moving on to mor complex brews.

IMO single malt and single hop brews can be quite hard to get right.

It's easier to "hide" stuff with a bit of malt flavour as well. A simple English style bitter, like a Landlord or a London Pride clone, is a very straight forward brew.

Magnum is a great bittering hop. Nice soft alpha delivery due to its low co humulone ratio.

Personally I would not use it as a smash hop. Not enough floral notes or fruity flavours for late hopping.

Right then do I throw caution to the wind and scrap the plan of a magnum smash as I have some citra hops as well.

I could use citra at the end instead of magnum?

Citra SMASH are some of the best.

This is one recipe I have used which has no bittering hops, I have also done similar and used Chinook for bittering and saved the citra for flavour/aroma. I usually aim for about 40-60 IBU.

For 23L 60 Minute Boil - 60 Minute mash at 66c

4.5Kg Pale / Marris Otter Malt

34g Citra 14.5%15 Minutes

33g Citra 14.5% 0 Minutes (30 minute steep)

33g Citra 14.5% dry hop (4 days)

For yeast US-05

Citra s m a s h is one of the best / easiest to get great results.

I would use around 20gm aa / bbl for 1hr

then add at -5mins,

EOB or Flameout

Then at + 15mins

a few grams in the FV doesnt hurt either

Be cracking with Europlis as the malt , or Vienna if you can find some

Update:

Then: My Saison was brewed with pale malt, goldings and sugar. Yeast was cultured up from a bottle of Saison Dupont, with an additional packet of Mangrove Jack's saison yeast. It was lush, with plenty of peppery, spicy and fruity flavours going on. I did have one bottle explode, possibly due to infection or possibly because this style is much more heavily carbonated than my usual brews, and the bottle wasn't strong enough.

Now: a London porter, closely modelled on the Graham Wheeler recipe for Fuller's porter. Pale, crystal, chocolate and brown malts and fuggles hops. Yeast is S04, recovered from a friend's brew. Currently conditioning, but promising, with plenty of coffee, chocolate and liquorice flavour.

Next: an English IPA. Pale malt, medium crystal and a touch of sugar. Fuggles for bittering and lots of goldings for aroma, mostly added at flameout and steeped for 30 minutes. Currently fermenting with Fuller's yeast, and I'll chuck in some more hops for a couple of days before bottling. I changed my process slightly on this one by doing a mashout to 75 degrees, and got a couple of points higher gravity than expected, so there may be something to it. I did a bit of water treatment - CRS to reduce carbonates and some gypsum added.

All brews are BIAB and no-chill.

Time for a long overdue bump. What's everyone been making?

I had success with a SNPA clone, though I added dry hops to suit my preference. One to make again.

Currently fermenting a Patersbier, loosely based on Westmalle Extra. I wanted an abbey ale with an alcohol content low enough to keep my legs working after two pints.

Next up will be a hoppy ordinary bitter, ready for summer guzzling.

I've got a part time job running a pub microbrewery now. I have also almost finished my MSc in Brewing & Distilling and am on par to get a Distinction, which I'm pretty proud of as the last time I looked at science was high school Chemistry and Physics in 1997! Going to write a thesis on propagating yeast for craft breweries using single use bioreactors. Very interesting! I like yeast.

Recent brews:

Gluten free Oatmeal stout

IPA (single hop Victoria Secret)

Double IPA (all the hops ever made)

Black IPA

Sorachi Ace Saison

Mixed fermentation (Sacc & Brett) Saison

60 Shilling

70 Shilling

Belgian Blonde

Berlinner Weisse

Eisbock

and just putting together a recipe for a Cherry Imperial Sour Smoked Wit with oak aging.

Which does seem like too many words.

And a Dunkelweisse I'm working on

Well this just turned up:

[url= https://farm1.staticflickr.com/802/40180155995_1a37292e72_b.jp g" target="_blank">https://farm1.staticflickr.com/802/40180155995_1a37292e72_b.jp g"/> [/img][/url][url= https://flic.kr/p/24dzNwg ]2018-03-28_03-40-47[/url] by [url= https://www.flickr.com/photos/7614571@N05/ ]thisisnotaspoon[/url], on Flickr

Green carpet and salmon walls by previous owner, monkeys and parquet models own.

First thoughts:

https://www.thehomebrewforum.co.uk/threads/the-postmans-been.76583/

Cheeky for sale plug of my old system:

https://www.thehomebrewforum.co.uk/threads/3-vessel-brewing-kit.76578/

My first ever 'professional' beer just went on tap at the pub I've started brewing for.

Having a pint!

It's a Black IPA and came out great - the pub owners are very impressed.

My first time doing cask beer too. Got the priming and fining just right.

Cheap too - craft beer @ £3/pint