![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

Morning all,

I've just bought a X0 crankset and a GXP BB, fitted the BB into the frame (Cotic Rocketmax) which has a 68mm shell; used the required spacers between the frame and the BB. Problem is the drive side rubs on the BB cups as the bearings are slightly recessed and there is approx a 2 - 3mm play in the crankset side to side. Am I missing something and being a bit thick (nothing else was supplied with either component).

Thanks, Maz.

Probably, in the right way round? Spacers on the right side? Remove it and have a good look, it's not rocket science but there shouldn't be play, my cranks stand away from the hope gxp I'm using

Too many spacers. Measure the shell to be sure but I reckon it's a 73.

Thanks for the replies, if I remove spacers though there will be more play surely? Should of said it's a X01 crank-set not a X0 if that makes a difference. Whichever way I try it the face of the drive side crank will rub against the body of the BB.

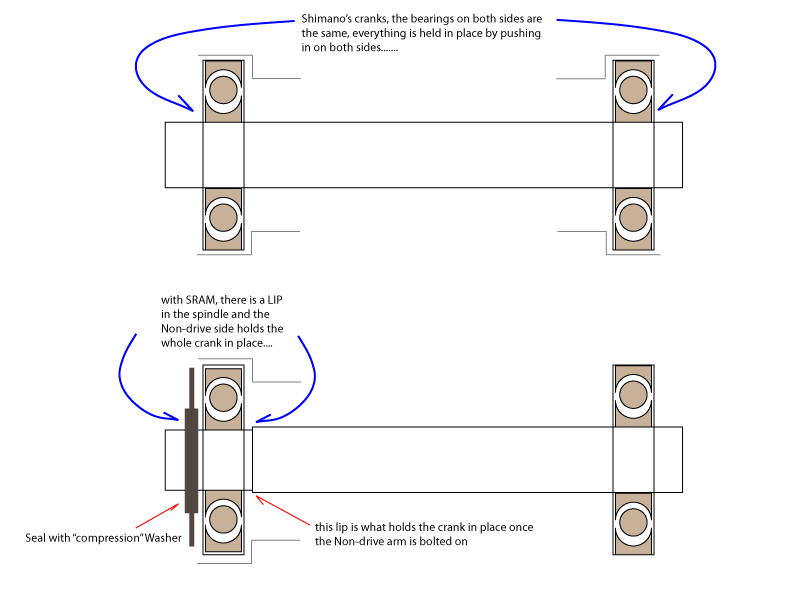

No the issue is that the ds bb shell is too close to the crank arm right now. Gxp is a fixed position system where the Nds bearing is clamped between the axle step and the nds crank, the drive side being essentially free floating. You should have about 4mm of axle exposed on the drive side. The reason you have play I suspect is because the nds side is. Not clamped onto the bearing right now as its in the wrong place.

definitely sounds like its a 73mm shell, with the extra spacers the axle cant reach the non drive side and locate properly, and doing it up to the correct torque will then pull the drive side arm into the bb itself.

This sounds like the issue you'd have if you forgot to install the metal collar inside the NDS bearing, on a non-SRAM BB such as Hope or Token.

But I assume if it's the SRAM BB that came with the cranks, the NDS bearing will be stepped down accordingly (or have a collar pressed in).

So, like some of the previous comments, it does sound like you've got too many spacers.

Have you actually measured the BB shell ? You can just use a ruler if you don't have vernier calipers.

Here's the step I'm talking about, on the LHS:

I believe the axle is 24mm diameter from drive-side all the way through, then steps down to 23mm.

When you tighten a GXP crankset, you're effectively tightening this step in the axle against the inside of the NDS bearing. Hence, as previously mentioned, the drive-side just 'floats'.

If you still get a tiny amount of side-to-side play, chances are your BB shell needs facing (paint removing, metal edges made parallel) to get it exactly at the ISO standard for 68 or 73mm