How loose is too loose?

As expected I had to gently pry the race off my old fork, but I can fit and remove it by hand on the new fork.

I googled it and came across a few accounts of a fork feeling loose due to a loose fitting race but those might be extreme examples...

Old fork (1 year old) measures 39.7mm and the new 39.6mm.

Is it fine?

Should I try a new crown race (but the existing one is still tight if I offer it up to the old fork)

Or should I point the finger at the fork and ask to exchange it?

Thanks!

Being able to remove the race with a little bit of force by hand is fine. I've had them from bastard-tight and having to hammer a lot to a snug fit and being able to push them on by hand.

If you can feel it's actually loose that isn't good.

Not loose as such but I can easily remove it with finger and thumb!

Don't think it should come off by hand unless it's a split crown but if there's no movement it should be okay, I've been using split crowns for ages but all crowns before that needed hammering on and off. If it was me I'd probably try to source a compatible split crown

New fork then a covert cut to the old fork that the race came off!

What's the UD of the crown race?

https://www.parktool.com/en-int/blog/repair-help/fork-crown-race-cutting-and-facing

First half is the new fork, second half is the old fork the race came from

I've got some that are bastard finger tight. Not caused an issue. If they move, or are *too* easy to remove, you need a new race/new fork/bodge to fix.

BTW, races can get stretch/deformed quite easily if they are hammered on and off to a very tight crown, a new race might help.

I assume it's not a split crown race. I'd be tempted to cut it and then it will conform to the right size under compression

Exactly what dc1988 said. I've cut them with a junior hacksaw and a fine blade and its been really successful. No dentist/hospital food scenarios across 6 bikes with tapered and straight steerers.

Fit the one you have. If it has play that you can't adjust out buy a new fork crown race.

The alternative is a bearing retaining compound, something like Loctite 675 will close 0.1mm diameter tolerances, but this will probably cost more than a correct race.

The alternative is to waste a pile of time and effort returning the fork with no guarantee of a better result

I assume it's not a split crown race. I'd be tempted to cut it and then it will conform to the right size under compression

That would be my suggestion too. i dont know what ive missed, but i cant fathom why split crown races are not standard.

having it fixed "a bit loose" doesnt sound healthy. I would want it "ruddy tight" by finger, at the very least. I would expect to have to get a pry under it, or give it a tap from the back.

Slotting the race with a hacksaw should sort it though, give it a bit of space to tighten up. (In one place only, not into two seperate pieces, just to be clear.)

but i cant fathom why split crown races are not standard.

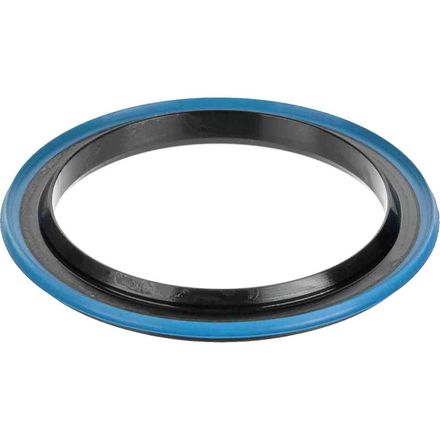

Because some / better / higher quality headsets have a seal integrated into the crown race to keep muck from ever getting near the bearings.

Obviously you can't cut through the seal or it's not a seal anymore.

I'd 2nd just buying a new crown race.

Maybe one of these images will post, maybe they won't, who knows.............

content.backcountry.com/images/items/large/CNE/CNE1WU1/ALU_D1.jpg

The Hope rings are split and have a separate seal which simply slots into a groove. A much better idea than that integrated one in the pic.

Not that it'll help the OP.

When you say "new fork"... is that new to you? Or box fresh new never been fitted to a bike before?

The Hope rings are split and have a separate seal which simply slots into a groove. A much better idea than that integrated one in the pic.

Fair enough, although Cane Creek back that one up with a lifetime, no ifs, not buts, warranty. So they're obviously confident in it.

Thanks for all the replies. Box fresh. I'm resisting the temptation to fit them, will get a split race first. Have emailed DT Swiss but suspect it's gone to TF Tuned as there was a suggestion they were the contact for technical issues.