![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

To start - I use a crud guard rear bracket to tap on a crown race instead of the specific tool.

What do you use to bodge jobs?

I use an old seatpost to tap out headsets.

screwdriver, hammer & vice - very little that combo can't achieve.

lol

ISIS cranks, 5p coil and machined shock spacer for crank tool to press against on axle to remove as had lost adaptor

Bench vice instead of normal bearing press.

Home-made headset press to, er, press headsets (and pull bearings).

Bit of metal tube broom handle to tap out headset cups!

I'm sure the list goes on, but then the flip-side is that it's also lovely to have the right tool for the job.....

DrP

If it can't be fixed with tie wraps and/or silicone spray then its not in need of repair in the first place

Old chain screwed to a piece of wood was a decent chain whip until I got one.

Socket set and various threaded bars and nuts as bearing presses and extractors.

I'm with the seatpost to bang out head sets.

Just learned the length of waste pipe to seat lower fork ball races

Alwyas bled brakes by using a synringe and plastic tube to suck fluid through. Could never be arsed to do the brake pumping thing - never failed me yet!

Seat post shims, pah! - cut up coke can is your friend

No chainwhip - it's amazing what you can do with a couple of rags wrapped in different directions around the sprocket

To start - I use a crud guard rear bracket to tap on a crown race instead of the specific tool.

For the same job, B&Q do a metal table leg that's the perfect size to slip over a steerer and **** a 1 1/8th crown race on.

I use a T-handled Allan key to fit star nuts. Slide the star nut onto the smaller wrench on the handle, hold the long wrench bit, and tap the heel of the handle with a mallet.

80% of the time, it works every time!

Re star nuts ...

Breadboard in top of them and a large wallop with a hammer seats them nicely ....

MrMoofo, my solution saves going to the kitchen to get the breadboard... Unless of course you fit forks in your kitchen, in which case, not a problem 😉

Oh, also, an empty tube of cadbury's mini eggs is the perfect size to press in the lip seals on Rochshox forks....

[img]  [/img]

[/img]

[img] https://encrypted-tbn2.gstatic.com/images?q=tbn:ANd9GcRZOA9PE0iMdY4B9OzoSEurgML-dbJSgnBeR3BJ0_Uuc6eqvu16 [/img]

DrP

vacuum cleaner tube - for installing headset crown races.

costa coffee orange juice bottle - pro II seal tool

vacuum cleaner tube - for installing headset crown races

+1

I have small plastic soft drink bottle, witha tube, and a bit wire copied from the bike guy in Les Linderats to assist with bleeding shimano brakes.

a broken crank arm from 1995 (square taper rounded off) is my lever of choice for adding length to any allen keys that need a bit more encoragement.

Threaded bar, nuts and large washers for pressing in headsets. Two spark plug sockets for pressing in cartridge wheel bearings. Handle from a trolley jack for extra leverage on allen keys.

Shimano rear quick release threaded through the hole on some cone spanners was effective for fitting a few headsets. Nice cam action. Gently, gently. Sorted.

Infact, pressing in a headset is the job the average home mechanic is least likely to have the proper tool for, thus requiring bodgeness.

Butter knife with a cut out of the end makes a great holder for the back screw insert for a chainring bolt.

My most used bodging implement is a rear axle out of a Suzuki SV650- makes for a fantastic drift, with extra shapes and flanges and such to get to awkward places.

zbonty - Memberpressing in a headset is the job the average home mechanic is least likely to have the proper tool for

But a rubber mallet IS the proper tool surely?

Plant sprayer with wand removed (like [url= http://www.screwfix.com/p/7ltr-pressure-sprayer/51100?kpid=51100?cm_mmc=Google-_-Product%20Listing%20Ads-_-Sales%20Tracking-_-sales%20tracking%20url&gclid=CKCIq5PB27UCFRDKtAodwHcAQg# ]This)[/url] as a compressor to seat tubeless tyres

Two allen keys as a substitute pin spanner got me home once.

If you have an electrical item which only has a European plug, no adapter and only a UK safety socket available, you can use a Yale-type key to push the earth safety bit in, which then opens the two other ports allowing you to jam the Euro plug in.

Probably not 'health and safety approved' though.

I used old external bottom bracket cups, a piece of threaded rod and some nuts and washers to press in a new bb92 bottom bracket. The external face size was a perfect match to the new bb's face.

Andy

Inspired by Kaesae, I made a split collet extractor for the Horst link bearings on my Stumpy using an old V-brake boss and a random bolt. Worked like a dream on a bearing that hadn't been touched for 7 years!

I use the decorative end of a curtain rail + threaded rod to seat star nuts.

Bit of plastic plumbing pipe to seat Pro 11 seals.

Drinks bottle compressor to seat ghetto tubeless tyres.

As a teen, i ran an extension lead from the house to the street and used my mum's electric carving knife to cut a hole in the plastic behind the front grill on my car so I could fit an induction kit. She still doesn't know and was a bit confused about the black plastic welded to the blades when she went to carve the Sunday roast.

Tyre lever makes an excellent tool for removing the plastic preload nut from Hollowtech II cranks

Mallet and chopping board makes a pretty good headset press.

I'll let you know about a hairdryer as a good way of unseizing bolts

The tube from a paint roller for installing crown races.

I used a claw hammer to remove the outer wall of a bearing from my carbon frame the other night. The bearing had fallen apart and a bearing knocker-outerer-thing wouldn't grip (integrated headset). Had to resort to the claw hammer and some gentle brute force to lever it out.

Mallet & plastic waste pipe for crown races..

Mallet & block of wood for headset bearings

Mallet & assorted sockets for sealed bearings

Mallet & anything else for all other jobs............

30 years ago I was a trainee mechanic,you never lose the skill of making do with what's to hand.............

Keep 'em coming ...

The reverse of this is I once opened a bottle of wine with a CO2 tyre inflator and a football adaptor. Nearly took my bleedin' head off but didn't spill any wine so happy days.

the 9p bottle of pop for inflating tubeless, and...... 2 or 3 links of a chain for removing the insert on the valves.

I just used an m6 rawl bolt, socket and washer instead of a blind bearing puller to do the horst link bearings on my stumpy! Lbs wanted 50 quid and 3 days just to pull the 2 bearings out of the ready dismantled rear triangle!!!! £5 and a pack of m6rawl bolts later the job was done in about 15min!!!

Rubber mallet + socket wrench extension = headset remover. The same mallet also puts headset cups in.

When I had Avid Elixirs on my bike and the pistons wouldn't go back where they belonged, after changing the pads, I found that a cone spanner waggled between the pads made enough space to allow the wheel to turn again!

🙂

A good boyfriend! Not one that you can just pick up from Aldi or wherever, but a real good quality boyfriend! Priceless bitof kit in my book 😆

Good thread. The shimano skewer works a treat as a headset press. Bit of a ball ache for 1.5" headsets, but still works.

Piece of hoover pipe for crown race installation. (+hammer, naturally)

And I thought I was rough using a chisel to remove crowns!

The grid for the win IMO.

smaller sized bolt/screw for the cheapo crank puller to work with the square taper

[img]  [/img]

[/img]

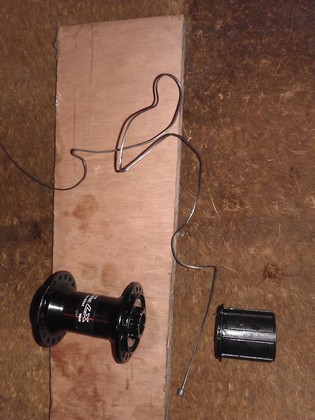

and yesterday, had to remove the freehub from a hub (not in wheel). old gear cable used to lace the hub around a strip of wood to hold it in place, worked a treat

[img]  [/img]

[/img]

On and on wins with the drain grate.