![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

"awaits flaming"

Yeah, I've got one of the Uno headsets in my SS Chameleon. It only got used in filthy conditions and it's still Ok after plenty of use.

I also have an uno in a SS chameleon but only had the bike up and running for a week or two so can't comment on reliability. Looks nice and went in with no issues, feels nice and smooth. I have some of their hubs as well and they also feel good. Freehub disappointingly quiet though 🙁

Yeah I've had a couple with no problems.

the cotic, hope and chris king evangelists must all be in bed dreaming of single speed jones monstrosities.

all the SS stuff ive had inc headsets has been just fine.

[quote=b45her ]the cotic, hope and chris king evangelists must all be in bed dreaming of single speed jones monstrosities.

all the SS stuff ive had inc headsets has been just fine.

Lol wide awake here 🙂

It's not that hard to get a headset right. Spec good bearings, fit good seals and make the tolerances right so there is no play.

It's even easier to work out if you find one and copy it 🙂The Superstar Grande Bambino Headset is our 1.5" reducer headset, same spec as the cane creek model but not £89.99!

Hope, CK & Cane Creek (high end stuff) have years of happy customers with 5-10 year life out of headsets to report back. SS haven't got there yet.

I was once told something very true

[i]"You will be happy if a cheap headset lasts a few years, but annoyed if an expensive one doesn't. Both are possible"[/i]

Which ever way face the tube, fit carefully and properly and look after it and it will probably be fine.

Like most of my Hope Stuff it's lifespan means the initial cost is largely irrelevant, the price per ride is tiny now.

Face the tube? Why?

[quote=toys19 ]Face the tube? Why?

Not to open an entirely separate can of worms....if the frame is used and has had the headset removed badly, it's not quite right out the factory or any other number of reasons. If you want to know it's done right then get it faced or at least checked.

I also accept that it's entirely possible fit a headset with a lump hammer and some wood and it work perfectly.

Proper fitting gives you the best chance (see above) of getting the most out of the headset.

yup not had any issue, my only slight moan is that their red is not very red but other than that they have some good sizes for semi integrated ones that are hard to find anywhere else (and at a good price)

Had one in since Xmas and its been fine

However, I did remove the forks a few months ago to oil the lowers and had considered swapping the lower and upper cartridges. The lower one was a bit reluctant to leave the steerer and opened up. I just repacked the cart with new grease and its been fine

I'll check and repack again each time I do the fork but for 15 quid I'm happy enough

It's not a can of worms, its a marketing rip rip off. Do some calcs and prove to me that the the cups deform due to a non-flat face, greater than the bearing angular tolerance and you might have a point. But they don't so you won't.

its a marketing rip rip off.

You do know were talking about the bike industry on this website?

I also accept that it's entirely possible fit a headset with a lump hammer and some wood and it work perfectly.

Is there another way?

You do know were talking about the bike industry on this website

Ha ha. Yes! Which is why I mentioned it..

[quote=toys19 ]It's not a can of worms, its a marketing rip rip off. Do some calcs and prove to me that the the cups deform due to a non-flat face, greater than the bearing angular tolerance and you might have a point. But they don't so you won't.

My lbs does it for nowt as part of fitting a headset. Can't quite see the MARKETING RIP OFF that seems to get hauled out whenever there is a change of doing something that either used tools that cost money or can't be done by balancing the frame and jumping on it.

More fool them for spending money on tools and wasting labour on a job that has no basis. Anyway it was you that was trotting out cliches sonny. Just do the calcs you will see its bollocks.

I've never faced a tube or BB and I'm always swapping frames etc about. Never had any issues with bearings apart from an ISIS bb but then that's ISIS bb's for you 🙂

I haven't used the complete headsets, but I'm using their replacement bearings in a Works headset just now, they seem fine... Time will tell how they last but they're already out of the woods as far as emo-ragingly early death goes. Good start.

mikewsmith - Memberif the frame is used and has had the headset removed badly,

Not being funny, but how do you remove a headset so badly that the frame needs faced afterwards, dynamite?

Not being funny, but how do you remove a headset so badly that the frame needs faced afterwards, dynamite?

I try and do it properly though seen some fairly heavy handed hammer & screwdriver jobs that have left the faces chipped and marked.

Facing is more about making sure both cups are paralell and removing paint less about cups deforming. Not a big issue on a well made frame.

I try and do it properly though seen some fairly heavy handed hammer & screwdriver jobs that have left the faces chipped and marked

Which will have zero effect on headset installation or life, unless you have some calcs or evidence that prove otherwise?

Facing is more about making sure both cups are paralell and removing paint less about cups deforming. Not a big issue on a well made frame

What would make the cups not parallel? The cups have 10-20mm of parallel stub going into a tube (also parallel) can you explain how facing influences how the cups go in?

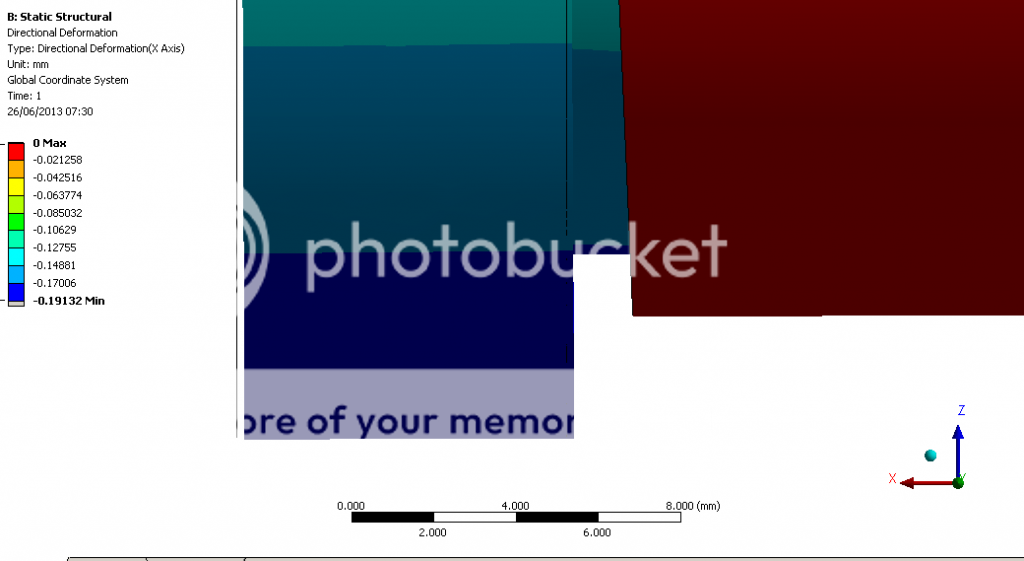

Ok for the nth time I have analysed this.

1) It is fixed at the right hand side of the screen.

2) Cut angle on the headset is 2.5 degrees, this is a common maximum permissible angular misalignment for a typical roller bearing. I set this to see what level of force is required to make the headset deform as much as the angular misalignment.

3) The cup stub faces are in contact with the inner faces of the tube, the bearing is in contact with the cup faces.

4) Friction coefficient on the tube walls is set as 0, as in my model there are no normal force on the contact faces so frictional resistance in the direction of movement will be zero. This is for conservatism, to allow the cups to try and conform to the face of the head tube without impediment, purely relying on the stiffness of the cups. The friction between the underside of the cup and the top face of the head tube is set to 0.25 potentially it could be higher..

5) The cups are aluminium alloy modulus 70GPa, the headtube is steel 200GPa, it is based on a 1/18th for tube, with 34.1 internal dia of the head tube, 1.5 wall thickness everywhere, feel free to offer me different wall thicknesses.

6) I have modeled the bearing as 100gpa, essentially half the stiffness of steel, to try and account for the fact that my simple representation fo the bearing (28.575 x 41 x 6.5) is a solid ring, so probs half of it is fresh air, so approximation is half the stiffness of steel.

The load is applied to the bearing face in the negative x direction - ie towards the right hand side of the screen.

2000n (approx 200kg) gives peak deformation at the point furthest from cup to head tube contact of 0.19mm

[IMG]  [/IMG]

[/IMG]

Zoom on 0.19 deformation, the original geom is shown in wireframe.

[img]  [/img]

[/img]

4000n (approx 400kg) gives peak deformation at the point furthest from cup to head tube contact of 0.36mm

[IMG]  [/IMG]

[/IMG]

Zoom on 0.36 deformation, the original geom is shown in wireframe.

Given that the gap is about 1.3mm, if you make the assumption that you can linearly extropolate, then you would need to apply approx 1400 kg to the bearing face to close this and hence make it worse than the angular tolerance of the bearing. Although I accept that by this point the cup will likely have yielded and collapsed. I cannot be arsed to to a non linear analysis though.

Please feel free to offer modifications/criticisms but to me this concludes that headset facing is pointless. I did the same thing for BB's a while ago if you need other proof..

Ever wonder if you're slightly over thinking bikes a bit? 😛

Ha yes, mildly OCD/obessive.

TBH this took about 10 mins to set up, and I prefer to get to the heart of the matter. Call it the War on Bullshit.

facing is a joyful thing to do, so if you have the tools do it.

o.O

What if the paint had run and left a thick blob under the bottom surface of the headtube and someone fitted it to that, eh. Eh?

Yeah. Yeah.

Eh.

[Just trying to make myself feel better about facing headtubes, perhaps]

EDIT ^^^ good post above me here 😀

1) It is fixed at the right hand side of the screen.

2) Cut angle on the headset is 2.5 degrees, this is a common maximum permissible angular misalignment for a typical roller bearing. I set this to see what level of force is required to make the headset deform as much as the angular misalignment.

3) The cup stub faces are in contact with the inner faces of the tube, the bearing is in contact with the cup faces.

4) Friction coefficient on the tube walls is set as 0, as in my model there are no normal force on the contact faces so frictional resistance in the direction of movement will be zero. This is for conservatism, to allow the cups to try and conform to the face of the head tube without impediment, purely relying on the stiffness of the cups. The friction between the underside of the cup and the top face of the head tube is set to 0.25 potentially it could be higher..

5) The cups are aluminium alloy modulus 70GPa, the headtube is steel 200GPa, it is based on a 1/18th for tube, with 34.1 internal dia of the head tube, 1.5 wall thickness everywhere, feel free to offer me different wall thicknesses.

6) I have modeled the bearing as 100gpa, essentially half the stiffness of steel, to try and account for the fact that my simple representation fo the bearing (28.575 x 41 x 6.5) is a solid ring, so probs half of it is fresh air, so approximation is half the stiffness of steel.The load is applied to the bearing face in the negative x direction - ie towards the right hand side of the screen.

2000n (approx 200kg) gives peak deformation at the point furthest from cup to head tube contact of 0.19mm

If you're so clever how come I don't understand anything you're saying? Nice colouring in though. 🙂

Interesting, toys19. Not that I understood any of it but it backs up my non-scientific gut instinct.

Nice colouring in though

Its important to try and keep it inside the lines I think. I always start with the edges. Once you get that sussed the rest just almost colours itself in.

Without doing or reading Toys FE up there I concur. The only reason I see for facing is if you have some damage to the entry which was dont while no headset was fitted that can't be cleaned up with a file etc OR if you don't want to see a slight gap between the cup and the headtube as a result of the headset bottoming out on one part of an uneven headtube.

The cup alignment is all in the interface between the inner walls of the headtube and the cup.

been involved in the trade on and off since 1987, done all my own spannering since 1987, the only time i would face a headset (or BB for that matter is on a customers new frame.

i have never bothered on my own frames, and typically for me, even a cheap headset will last a decade or more as long as its properly greased up and correctly adjusted.

YMMV of course, but thats been my experience.