![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

It's like being back in the mid-90s! 🙂

I'm loving the bonkersness.

Think I will stick with sids

Doesn't he need his?

the suspension aspect of it looks crap but the engineering side is fantastic

Looks cool, weren't RST doing something similar with elastomers and a pivot arround the steerer/fork junction?

Surely that isn't strong enough to take big hits?!

DT78 - MemberSurely that isn't strong enough to take big hits?!

Re-read the details - it's for a 29er, no big hits will be encountered hence no problem.

I shit you not, but I was sponsored by sainsbury engineering trust at uni and my tutor and I designed almost exactly the same fork as the first year project with a wound carbon spring (not leaf) and the linkage was at the fork crown not the axle ! Spooky dook

I wonder what the fast lads on the 29" rigid race bikes will make of that?

I'll take the on-one budget version for a bit of comfort on my rigid singlespeed.

Now it's very possible i'm getting this wrong, but isn't approx 1kg for 60mm of (underdamped/non adjustable) travel really not that impressive? How much mass does the lightest short travel conventional airsprung fork have??

Interesting, what's the life span on those?

5 year guarantee offered and 130000 cycles on the test bed from the link

PS how would you service that bad boy ...cynicAl would have you out of business in weeks with his spoon bodgery 😉

but isn't approx 1kg for 60mm of (underdamped/non adjustable) travel really not that impressive? How much mass does the lightest short travel conventional airsprung fork have??

~1500g for some top end 29er Sids. I bet the most common rigid forks on here is the [url= http://www.on-one.co.uk/i/q/FOOOCAR/on_one_carbon_fork ]On-One[/url] style jobbies, which weight almost exactly the same as the above.

A lot of race frames are still built around 80-90mm forks anyway. 20-30mm travel lost, for 1lb weight saving. Looks to be mud proof and have a ton of clearance at the top as well.

How does it resist the twisting from the disc? Even my old Maverick SC32's used to veer to one side slightly.

A lot of race frames are still built around 80-90mm forks anyway

Total rubbish. In reality very few are, the size 15in Specialized have 90mm forks, but almost every other bike is 100mm.

The guy riding it in the pictures looks like he could lose about 20lbs before worrying about losing the weight from his forks.

How does it resist the twisting from the disc? Even my old Maverick SC32's used to veer to one side slightly.

Indeed.

I think fork mounted camera footage of it's lateral tracking through ruts would also be interesting.

I thought they were having a " Lauf"

I'll get my coat 😆

it doesn't matter if the travel is only 60mm or so as long as the axle to crown is adjusted accordingly in the design so it won't steepen the head angle on frame for 100mm. My issue is the 45mm offset..would feel old skool 29er pretty barge like on a lot of 29er frames that have moved on and designed for longer offsets.

Total rubbish. In reality very few are, the size 15in Specialized have 90mm forks, but almost every other bike is 100mm.

Slightly dramatic reply there to 10 mm 🙂 My point still stands.

I'm using a 23" 2012 Stumpy HT at the moment which uses 90mm*. Prior to this I used a Scandal which was corrected for 80mm. Cannondale still use 80-90mm on all 29er hardtails? I think Specialized + Cannondale alone would constitute "a lot" on the subject of racey bikes? 🙂

*[url= http://www.specialized.com/us/en/bikes/mountain/sjht/stumpjumperelitecarbon29#specs ]http://www.specialized.com/us/en/bikes/mountain/sjht/stumpjumperelitecarbon29#specs[/url] - this years models, 80mm for smallest, 90mm for the rest.

but the engineering side is fantastic

Any engineer worth his/her salt would notice a major flaw with this design straight away... 🙄

hmmm, so if I understand this correctly its a carbon spring, relying on some "inherent" damping in the carbon? ( more likely any damping comes from the resin system the carbon springs are laid up with, if there is any resin?)

I wonder if you took a decent light weight 80mm travel trail fork, took all the damping kit and oil out of it, and replace the steel/titanium spring with a carbon equivalent spring if you would not be far off the same weight?

Goes to check calendar to make sure it's not April 1st.

It's going to self steer something crazy, there's only the axle trying to keep the left and right sides in sync...

Its a load of tosh, forget about it.

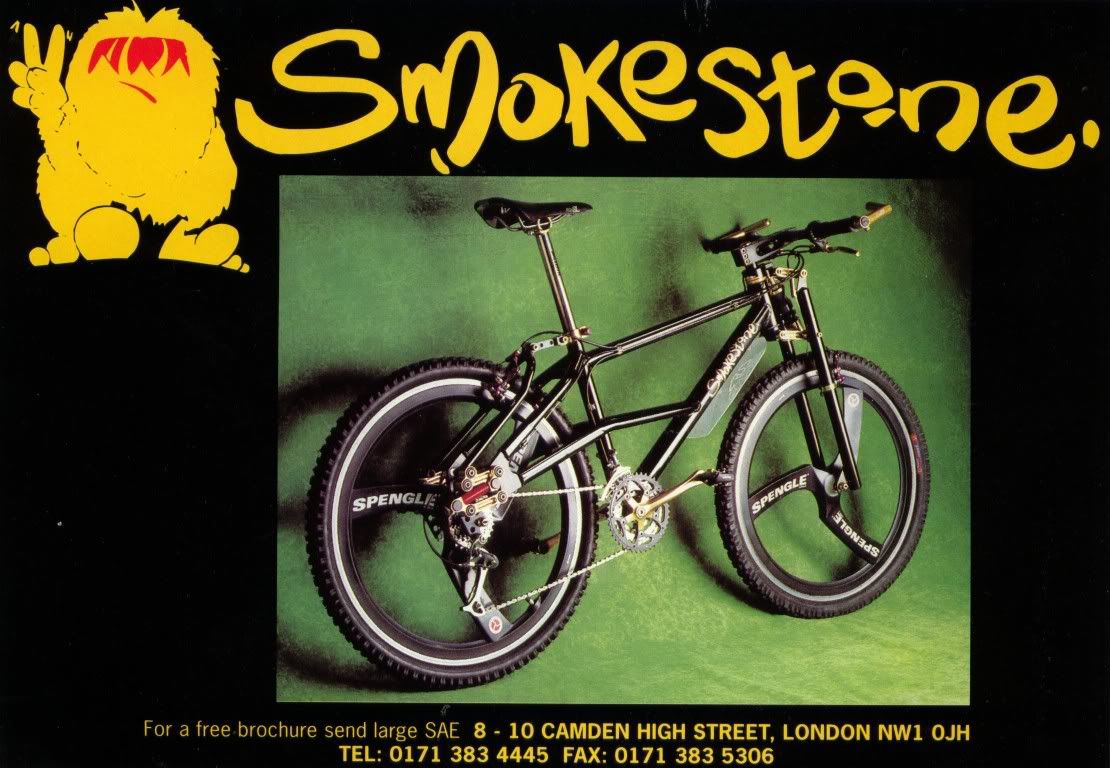

That Smokestone looks a bit crazy. Reminds me of those home modified bikes that came up on eBay about six months ago...

Just read CFH's thread and its lead me here to comment..

I like the engineering angle, well thought out, prefer the knitted jumpers though.

Wouldn't have it on my Niner, sorry.

Lots of assumptions in here tonight.

Who knows if this is less stiff than a conventional fork as there is no data.

Damping - why would there be no damping? Play tennis with an aluminium racquet and then with a carbonfibre one and tell me they feel the same.

60mm of travel is still better than a rigid fork.

Brake twist - maybe they are designed to resist the braking loads? Again no data to say either way.

I like it. Now build a frame with similar technology for the rear and give me a 60mm travel 1.2 kg full suspension frame.

I like it. Now build a frame with similar technology for the rear and give me a 60mm travel 1.2 kg full suspension frame.

undamped frame with no rebound control? pedal-bob-a-rific surely?

If braking forces cause flexible. It's more likely to make the wheel cant sideways to the right - its well reinforced fore/aft.

I like it. Innovation is good. Could something bonded in between the leaves a la Softride, for damping?

You have to wonder about a single sided version?

undamped frame with no rebound control? pedal-bob-a-rific surely?

10/10 for missing my earlier comment on damping.

Al - yup, completely feasible that something could be placed between the springs to change the damping but you could also just swap out the springs with ones with a different properties such as different amounts of viscoelastic materials.

Might see it on Paris-Roubaix

Seem to have submitted a patent... no pics though

https://www.google.com/patents/WO2013046236A1

Cool idea, for added awesomeness I think it needs some holes drilled in it somewhere and some purple anodising incorporated into the colour scheme...

It's a very clever simple idea. I think the tracking issue is probably lessened by the through axle?

10/10 for missing my earlier comment on damping.Al - yup, completely feasible that something could be placed between the springs to change the damping but you could also just swap out the springs with ones with a different properties such as different amounts of viscoelastic materials.

0/10 for assuming that just becasue you typed it, it must be true. I'm sure he read it, just decided it was incorrect. How much damping is there in that carbon? Eff all compared to an actual damper unit. You can see from the video it bobs on small bumps. The tennis racket analogy is incorrect, the carbon racket feels more flexible because it is more flexible. Nothing to do with damping.

A lot of assumption and speculation going on here based on a couple of photos and a video clip.

Perhaps, assuming that this is a commercial venture and not just a design exercise, one will be made available for test. The only way to tell if it works would be to let somebody actually ride it.

The 'spring' bit isn't new, it's just a flexure. Used all over the place (eg F1 suspension) to give friction free movement. Look in any compliant mechanism text book.

How does one adjust spring rate?

You don't, three different stiffness's available.

How does one adjust spring rate?

Thickness (or construction) of the flexure.

The 'spring' bit isn't new, it's just a flexure. Used all over the place (eg F1 suspension) to give friction free movement. Look in any compliant mechanism text book.

Or any old horse cart in a museum.

Hold on - the two sides aren't linked, are they? What's to stop it deflecting left to right besides the axle being clamped in?

I'd have to ride it, to be honest.

What's to stop it deflecting left to right besides the axle being clamped in?

The axle being clamped in it.

Its not a massive problem on upside-down forks, like Mavericks, where the two lowers are only joined by the axle. And i guess the flexures are designed to flex vertically and be stiff sideways.

Bonkers. Probably even quite good in a few situations. Ugly. But I love the fact they've got the balls to try something different, regardless of what the armchair (and real) engineers on the forums say.

Must have missed the 3 different versions, bit of a bugger if you turn into a porker!

Reminds me of the Amp forks of old. I'd like to see the reviews, and try before i buy.

0/10 for assuming that just becasue you typed it, it must be true. I'm sure he read it, just decided it was incorrect. How much damping is there in that carbon? Eff all compared to an actual damper unit. You can see from the video it bobs on small bumps. The tennis racket analogy is incorrect, the carbon racket feels more flexible because it is more flexible. Nothing to do with damping.

My response was to people implying that there is absolutely no damping. Yes achieving the levels of damping seen in a discrete traditional damper is going to be very hard but there is a hell of a lot you can do with composite materials to increase and control the damping and the levels that can be achieved vary greatly and it does not have to rely on the overall stiffness of the whole structure.

You need to stop thinking about the whole picture and start thinking on the micro and nano scale at how to dissipate energy at different frequencies. The slow speed damping is going to be the challenge here.

But until anyone knows what they have done that is not visible and in the press release it's completely unfair to say there is no damping.

@molgrips: With regards to flexing from the side you just design the flexibility in directions you want and make it stiffer in the directions you don't - ie side to side and twisting. Remember with composites you have the effect of fibre orientation to play with as well as geometry.

Can the springs be removed and replaced with different rates?

If they can, i guess you don't need to run all 3 the of the same rate?

And comparing it to the AMP etc designs, it does has very low unsprung mass, which is a good thing.

Of course, but I'd still expect somewhat worse tracking than a traditional fork. But I would like to be surprised 🙂

It could be a good thing for a TDR race or similar, although I would not choose one until they had been around for a long time to prove reliability.

Thats very neat, I cant see the tracking being a problem if you look at where they have engineered the stiffness.

The design is only compliant in 1 direction (Z)

In X it is a classic 4 link only seeing compression and tension loads

In Y the spring blades are stiff in beam.

the main Blades (Fork legs) are deeper in section than they are wide, again adding to the fore / aft stiffness, Id be very surprised if they were not greater in torsional stiffness than conventional 29er suspension forks

The only thing stopping one side compressing more than the other is a 15mm Maxle, and i'm not sure it was designed with that in mind as most fork lowers are held together rigidly.

The Maverick fork used a custom 24mm one and was still a bit wobbly.

HoratioHufnagel - Member

The only thing stopping one side compressing more than the other is a 15mm Maxle

Id suggest you go back and look at it again as a complete system.

And work out which bits can move and in which direction relative to one another

The Maverick fork used a custom 24mm one and was still a bit wobbly.

It also had an insanely light crown made from a hollow piece of metal welded tot he uppers. An example of how weight weenie they were when making it, IIRC the DC version didn't have a steerer tube, just a crown race on the uppwer and lower crowns!

Yes achieving the levels of damping seen in a discrete traditional damper is going to be very hard but there is a hell of a lot you can do with composite materials to increase and control the damping and the levels that can be achieved vary greatly and it does not have to rely on the overall stiffness of the whole structure.You need to stop thinking about the whole picture and start thinking on the micro and nano scale at how to dissipate energy at different frequencies. The slow speed damping is going to be the challenge here.

Damping coeffecients:

Steel 0.0004

Aluminium 0.0001

Carbon 0.1

Typical MTB fork 100's

So yes carbon damps at orders of magnitude greater than steel or aluminium, but we are not talking about high frequency (100s Hz) low amplitude (<1mm) vibration here. When this thing deforms we are talking 10's of hz at most, and many mm. For critical damping (ie to stop it oscillating, bouncing back more than once) it needs a damping ratio of 0.24-0.4 (crit damping is 1, but that makes suspension feel tto stiff) which with a damping coeefcient of 0.1 means that either the spring should be soft (which compared to a normal fork spring, it will be similar, so not) or sprung mass should be very very light. It isn't.

But until anyone knows what they have done that is not visible and in the press release it's completely unfair to say there is no damping.

PS I can read - Chipp's article said no damping..

if only on a technicality – no moving parts.

Oh, and there’s no compression and rebound damping apart from that inherent in the carbon leaf springs

Look I'm not dissing the fork, it might work well, but it is a technical fact that will not have any damping like a conventional fork.

No thanks.

No mention of a 26er option?

Would be interested on the winter bike due to low maintenance plus.

Speculation sucks. Coincidentally, visiting Iceland soon - I can feel an email coming on......

Also got some reference points to compare them with - we were mtb kids of the 90's, so actually owned Girvin Vector and Quasar linkage forks (still got a slightly broken set of Quasars in the attic)

Bump! Seems they're going into production and they're going to be getting us a test sample when they do. I will be happy to let any of you lot have a go (believers and non-believers) if you come and visit the office some time. Any takers?

Bring one out on Monday night. You'll get a full spectrum of fast to fat.

What frame/axl/wheel spec would they need Chipps?

They'll be 29er and 15mm I'd have thought. No word on when we might see on yet.

As a weight weenie 29er rider I'd be well up for checking those out chipps.

I had a look at these at eurobike, could be quite useful. Can't quite get over the looks-vs-benefit thing (despite some of other the stuff I own..) but I like the lack of moving parts and I'd be quite keen to try a toned-down 'CX' version for bikes that can't use tyres for any reasonable cush.

They were also talking earnestly to some fat bike companies... Might be interesting.