Getting a few things off my mountain biking chest.

Sometimes it’s good to moan. It can help get rid of frustrations. A problem shared is a problem halved and all that. Clear the air and move on.

With that in mind, these are the 10 main things that have been bugging me with bikes for the past few years.

Semi-lightheartedly, here goes nothing…

Carbon (apart from rims)

Let’s kick things off with a biggie. Aside from the ecological argument (that I don’t want to get sidetracked by), I just don’t think carbon is worth the money. The amount of extra £-pounds you have to spend to save one or two lb-pounds is faintly outrageous. Arguably most of that weight saving is due to the bike industry seemingly having given up on even trying to make metal bikes light(er), especially North American brands. And a lot of the time I think it’s a worse performing material than metal. The one exception is wheel rims. Carbon rims can be the best rims available. Still loads of money, mind.

High-set helmet peaks

I’m going to pin this one on Specialized. Although other brands are hopping on board this aesthetic, I think Spesh was the first to bring out helmets with peaks set bizarrely far-too-high. High to the point of actually being pointless. Even if you don’t live anywhere that sunny, these high peaks now make dusk rides an exercise in squinting and, quite frankly, dangerous.

Thru-headset anything

Yep, the classic. People may be bored of moaning about thru-headset cable routing but we need to keep up the pressure. Not only does it add complexity and cost to routing service jobs, it doesn’t even look better than regular routing. It’s a disease that’s drifted over from dropbar bikes and it can drift off back there thanks.

Torx bolts

Is it just me, or are torx bolts more prone to rounding out than Allen key bolts? Especially on items that aren’t disc rotor bolts. Any test bike from torx-tastic Scott, for example, usually ends up heading back post-test period with all of the torx bolts looking scratty and mashed. Hex FTW.

Disc mounts on chainstays

Am not exactly sure if brands are putting calipers on the chain stay for suspension-v-braking reasons but I am sure that such a location makes it much more difficult to get at the caliper mount bolts, especially with a multi-tool. And as for the introduction of the patently awful flat-mount standard coming in from roadie world… No. Just no. Can’t we just bring back I.S.? That was clearly superior.

Tokenistic adjustments

One reason why I don’t pick on brands that don’t offer proportional chainstays or flipchips, is because the brands that do offer these things very rarely do it to a sufficient degree. 11mm difference in chain stay length between Small and XX-Large? 0.5° change in geometry via a flipchip? Hardly worth it. If you’re going to market sizing/adjustments, at least make it justifiable.

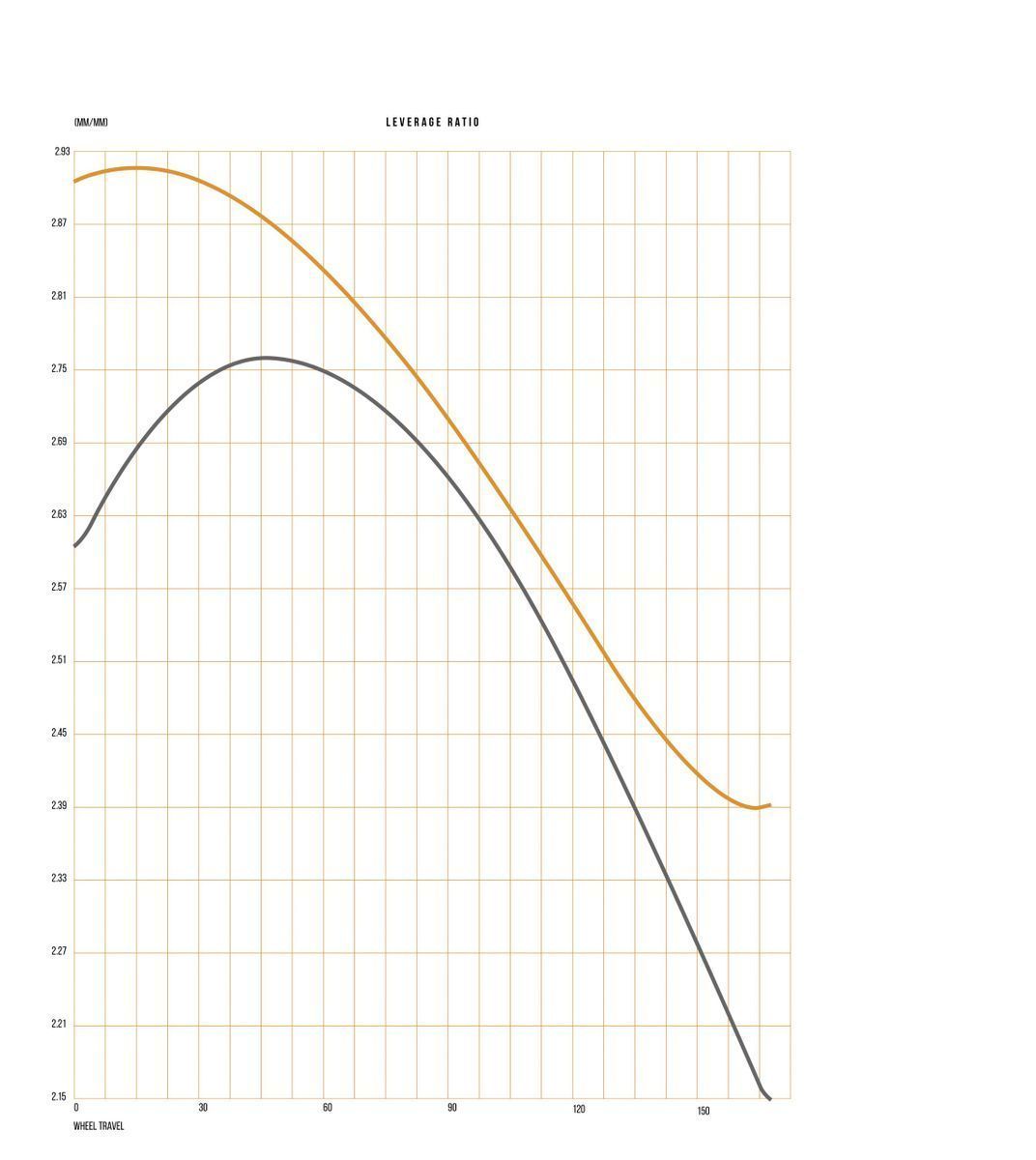

Curvy rates

Whether this is suspension frame leverage or air springs, I rarely get along with curves that aren’t consistent. I can get them to function okay but in a world where most riders (understandably) don’t want to spend hours and hours setting up a pushbike, these curves are often a recipe for extremely poor bike setup and thus handling. The marketing idea of ‘supple at sag, rampy at the end’ is not what a lot of riders end up sat on.

Silicone grippers

Helmets. Knee pads. Liner shorts. Any of these that have silicone grippers frequently get on my wick. Sometime literally. Essentially using hot glue to keep cycling apparel in place. Ugh.

Car industry aping

All these ‘Works’ bikes. Or eebs with stronger motors in the top tier models. Feels very Beemer M Series. Naff.

And finally…

The tenth slot is open to you. Add your suggestions below!

It’s very easy to raise the bars. The opposite is basically impossible without a long stem.

I am not a fussy person, I’ll buy what works and or is on sale, but that stem disgusts me.

It’s easy up to a point, but there are limits to it. As I get older, my bars are getting higher and I write off may potential drop bar bikes due to low stack. I also see a load of people riding around with bars that are probably lower than ideal for them.

Is it just me, or…

Harsh assessment and entirely unfair on the Ood in my opinion.

I’m afraid to say I bought a bike with hoses through. Hate it but buying an SL eBike, tradeoffs had to be made and I chose that so I could have other things I cared more about.

Manufacturers using poor quality bolts? (material and tolerances)

Mondraker Neat has this. With the standard brakes on some spec levels, you can’t undo the brake pad retention bolt without removing the caliper.

Worst blister I ever had – crack developed in Sealskinz socks with Hydrostop, rubbed the back of my calf on a ride, only realised when I took them off.

Yeah, my skin reacts badly to certain grippers. At various times I’ve had the words Endura, MT500 and Gore written into my thighs.

Torx bolts on seatpost heads are bloody annoying, as you can’t spin them up to low torque with a ball end, so it takes ages.

The other issue with torx, is that generally three size tools fit on bolt! So many times I’ve thought ‘pretty sure that is the right size but I’ll try the next size up to be sure’, and yes it’s the next size up. Might explain the rounding off issues that some people have.

That pasta eating stem is one of the dumbest looking things I’ve seen on a bike, and I would immediately strike whatever brand that is (Focus?) off any future purchase list as a result!

I’ve broken way more steel frames than carbon frames.

Why can you never buy a bike with Rockshox suspension but shimano drive train? Infect why do most bikes come with sram drive trains whatever the suspension. Presumably sram sell it dir5 cheap to oem knowing it will fall apart and the can fleece the customer on replacements

Stop giving influencers free stuff. You never get an honest review, and nobody wears a helmet to the coffee shop, cafe, toilet, shower. Take the bloody thing off you disrespectful idiot. Yes that free £15k bike must be nice but you didn’t pay for it, nor are you doing the fixing or replacing the worn bits.

This is the way.

Bike industry: stop up-speccing the rear mech on new bikes. Yes I know it’s the obvious bit that folk will be drawn to look at, but I’d much rather that money was spent on a higher spec shifter than the rear mech. Touch points matter more than a blingier rear mech.

You can, as I said above, torx is designed to wiggle like a ball end. The sloppy fit is in fact a deliberate feature, not a bug!

There’s also a “Torx plus" which is similar but the points are rounded off (and therefore wider) and has a 0deg drive angle (no wobble). You can use a torx bit in torx-plus fasteners, but not vice versa. It’s not been universally taken up because while it tends to cam out less often and tools wear out slower, the original torx is designed to engage while moving, so if you’re screwing together a hundred Dyson hoovers an hour in a far eastern factory you don’t need to be so accurate with when you press the button on your electric screwdriver.

I’ve only ever seen torx plus on really expensive kit like camera lenses, or where it’s just trying to feel expensive (IT components).

A way back someone posted up the (large scale) OEM price for SRAM brakes, it was something ludicrous like £5. And yes they offered discounts if you bought a SRAM groupset, RS fork, Truvative bars/stem, reverb post etc. Which is why you tend to see Shimano + fox, if they don’t spec a SRAM drivetrain then they get a worse price, so the spec ends up looking worse than their competitors.

Bottle cages with hard to reach bolts. I have a bottle cage with a built in multi tool. It is so awkward to get to the bolts that it is impossible to do with the supplied multi tool.

in days of yore, higher spec mechs were superior to lower spec and the shifter was pretty much the same unit rebadged, once you got to a certain level anyway. nice mechs lasted longer. however this isn’t really true anymore, trickle down tech perhaps, but mechs don’t seem to be as fragile as they were. maybe with the advent of more gears (10+) the smaller shifts = smaller movements per shift and less wear, or maybe just better quality for lower cost wear parts.

on that though, there is a difference shifting XTR to SLX, but is there a difference from GX to XO or XX?

No, but that’s because XO and XX are electric only, when comparing to electric GX. They are a bit lighter, and have a couple more features, but shifting is the same.

re the number of tools/bolts, I remember once replacing a front shimano brake and rotor.

From memory I think that required:

front axle 6mm

brake bolts 5mm

lever to bar 4mm

pad retention bolt 3mm

hose clamp on fork 2.5mm

release clip to take lever off 2mm

rotor bolts T25

House!

interesting, the sram site still lists the mechanical versions alongside AXS.

I would like the cycling industry to stop peddling both electric Mountainbikes and road bikes.

Electric cargo bikes. Commuter things. Fair enough. They serve a purpose and (hopefully) remove cars from the roads.

Electric mountain bikes and road bikes don’t need motors. You’ve got legs. You managed for years without them. Why do you need them now?