Getting a few things off my mountain biking chest.

Sometimes it’s good to moan. It can help get rid of frustrations. A problem shared is a problem halved and all that. Clear the air and move on.

With that in mind, these are the 10 main things that have been bugging me with bikes for the past few years.

Semi-lightheartedly, here goes nothing…

Carbon (apart from rims)

Let’s kick things off with a biggie. Aside from the ecological argument (that I don’t want to get sidetracked by), I just don’t think carbon is worth the money. The amount of extra £-pounds you have to spend to save one or two lb-pounds is faintly outrageous. Arguably most of that weight saving is due to the bike industry seemingly having given up on even trying to make metal bikes light(er), especially North American brands. And a lot of the time I think it’s a worse performing material than metal. The one exception is wheel rims. Carbon rims can be the best rims available. Still loads of money, mind.

High-set helmet peaks

I’m going to pin this one on Specialized. Although other brands are hopping on board this aesthetic, I think Spesh was the first to bring out helmets with peaks set bizarrely far-too-high. High to the point of actually being pointless. Even if you don’t live anywhere that sunny, these high peaks now make dusk rides an exercise in squinting and, quite frankly, dangerous.

Thru-headset anything

Yep, the classic. People may be bored of moaning about thru-headset cable routing but we need to keep up the pressure. Not only does it add complexity and cost to routing service jobs, it doesn’t even look better than regular routing. It’s a disease that’s drifted over from dropbar bikes and it can drift off back there thanks.

Torx bolts

Is it just me, or are torx bolts more prone to rounding out than Allen key bolts? Especially on items that aren’t disc rotor bolts. Any test bike from torx-tastic Scott, for example, usually ends up heading back post-test period with all of the torx bolts looking scratty and mashed. Hex FTW.

Disc mounts on chainstays

Am not exactly sure if brands are putting calipers on the chain stay for suspension-v-braking reasons but I am sure that such a location makes it much more difficult to get at the caliper mount bolts, especially with a multi-tool. And as for the introduction of the patently awful flat-mount standard coming in from roadie world… No. Just no. Can’t we just bring back I.S.? That was clearly superior.

Tokenistic adjustments

One reason why I don’t pick on brands that don’t offer proportional chainstays or flipchips, is because the brands that do offer these things very rarely do it to a sufficient degree. 11mm difference in chain stay length between Small and XX-Large? 0.5° change in geometry via a flipchip? Hardly worth it. If you’re going to market sizing/adjustments, at least make it justifiable.

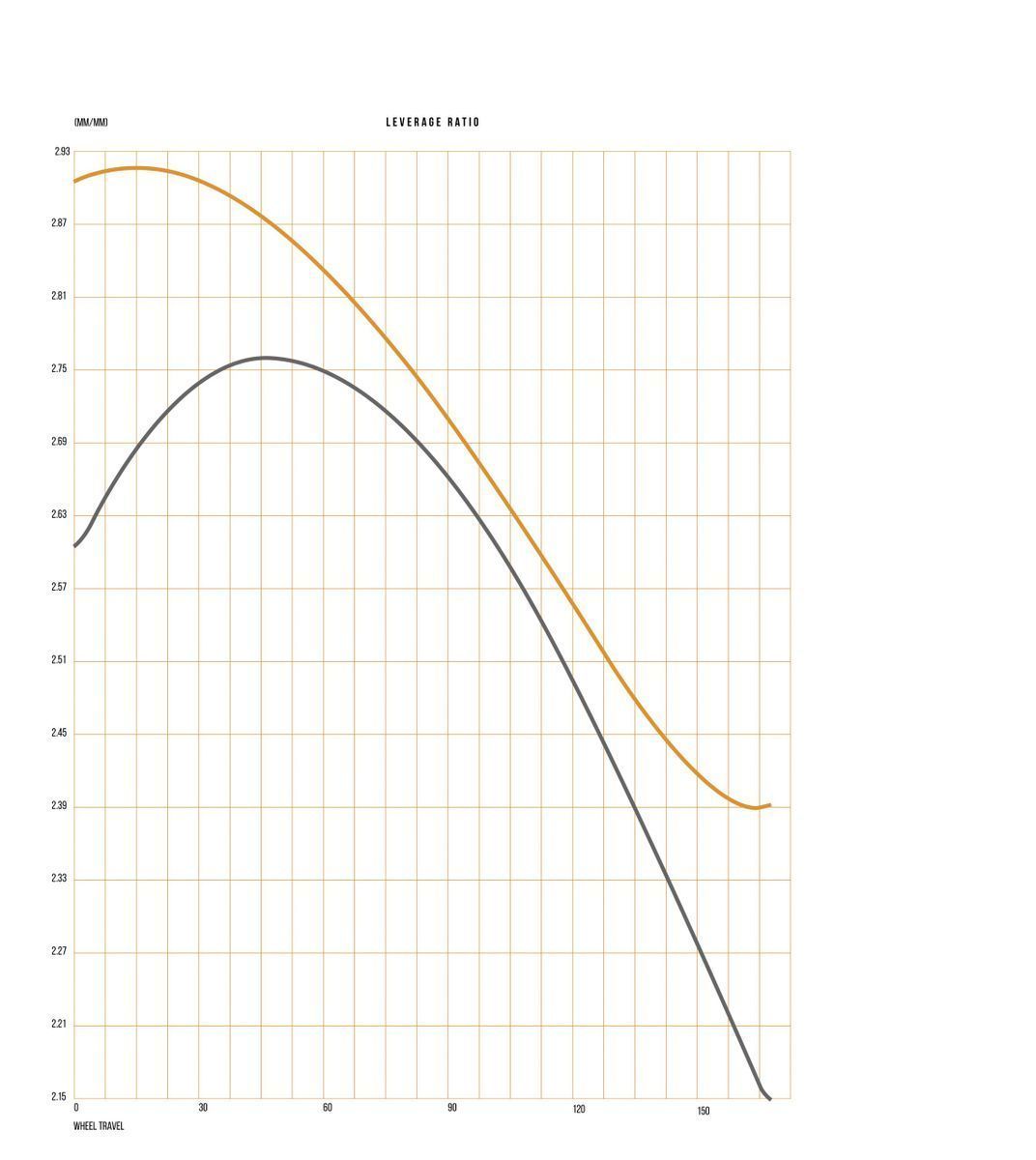

Curvy rates

Whether this is suspension frame leverage or air springs, I rarely get along with curves that aren’t consistent. I can get them to function okay but in a world where most riders (understandably) don’t want to spend hours and hours setting up a pushbike, these curves are often a recipe for extremely poor bike setup and thus handling. The marketing idea of ‘supple at sag, rampy at the end’ is not what a lot of riders end up sat on.

Silicone grippers

Helmets. Knee pads. Liner shorts. Any of these that have silicone grippers frequently get on my wick. Sometime literally. Essentially using hot glue to keep cycling apparel in place. Ugh.

Car industry aping

All these ‘Works’ bikes. Or eebs with stronger motors in the top tier models. Feels very Beemer M Series. Naff.

And finally…

The tenth slot is open to you. Add your suggestions below!

I was a metal frame enthusiast too, but I have just replaced an alu-framed enduro bike with a (low-priced SH) carbon one – and I have to reluctantly admit it’s a big improvement for me.

I believe that there’s a much bigger profit margin on carbon bikes, so perhaps what the bike industry really needs to stop doing is seeing them as a cash cow?

Is there a similar mark-up on carbon rims? For now I reckon most of us who pay for our own rims will stick with aluminium anyway.

If you want to ban a frame material Ti is the low hanging fruit. Expensive, high hassle and energy to build for no point bar fashion points

Cause we recycle our titanium obvs….

The best bikes I’ve ever owned have been carbon. And the big differentiator has been comfort rather than weight.

Yep, gets me every. single. time.

I hadn’t even clocked it was Ben who posted this, but hells yes. 32″ is not going to be a new standard, stop pretending it will be/ trying to create yet another “standard" that forces everyone to replace their entire bike/ parts collection

Sponsored articles

With you on the pointless helmet peaks, and exactly same manufacturer; I bought a Specialized helmet with a large peak specifically for commuting as large sections of my commute in either direction had the sun in my eyes. The Specialized peak was literally 100% useless.

The Fox helmet I have OTOH, is brilliant, so I suspect it’ll be discontinued six months before I decide to replace it, and due to the actually functional peak, people will snap it up inflating the price of any remaining stock.

That’s it. Discontinuing product lines that actually work well for those on smaller budgets because they’re not in line with the latest & greatest.

Peaks are there to serve as go-pro mounting points rather than sunshades, grandad(s)

Not a terrible price to pay if you want cycling media to survive though, surely?

STW do a good job of marking their advertorial stuff anyway.

Torx is ……… divisive. Fundamentally it’ll strip the tool before it strips the bolt, rather than the other way around. And I hate how loose the interface on some fastens feel, the suspension mount on my motorbike are great big 1/2″ 8.8 bolts, and the T45 bit feels very precarious in there. I know it’s designed like that, it’s original USP was that it could be driven in at an angle, but it still feels completely wrong. IT actually works/feels much better with a proper ratchet set and bits where you can push the bit in with one hand and apply torque with the other. With keys the ‘bit’ tends to fall over at an angle when you turn it.

So on the one hand if you mash the tool you’ve still got a 2nd chance. On the other hand a similarly sized hex would not have slipped in the first place and if the bolt is stuck then trashing several tools before taking the grinder to it isn’t any better than rounding it off and taking the grinder to it.

There’s a commercial logic to it though.

Say you’re a big brand and need to produce low, mid and high tier component ranges. Not a niche company that only makes high end components.

If you make just those three, then your R&D budget only needs splitting 3 ways (probably skewed tot he top end). If you need to make XC, Enduro and DH versions now your top end budget is split 3 ways and the lowest tier budget barely covers the graphic designers crayons. So it very much depends whether spending 3x more on the top end R&D results in a crank that isn’t any heavier than the XC version or weaker than the DH version you would have developed.

When the fashion was towards lighter bikes, plenty of DH riders were running XT cranks. And I remember a race report in Dirt where Sam Hill bent his Truvative cranks every single run of the weekend. Srams DH cranks weren’t as strong as Shimano’s ‘XC’ offering! The light/cheep/strong mantra is still true, but you can make it cheaper just by economies of scale.

I have an 8 on the rear of one bike! Most multitools don’t have an 8!

It’s not even sensible.

Tiny, barely adequate 4mm bolts on a stem to save weight, then things like brake levers get 5mm bolts that barely need to be finger tight. Or worse, a mix of 4 and 5 on the same stem! Component brands really should have standardized on 5mm for everything on the bars then just made the brake/shifter/dropper clamp molts from aluminum.

Same goes for other components like suspension and saddles – just call them “good" , “better" , “best" , “pointlessly expensive but in our range because someone will buy it". For suspension I’m familiar with the RS naming and just CBA to try to understand Fox etc. Also looking for a new saddle and some come in different variants of the same shape but with small differences – just makes it harder to work out what you actually want.

What a weird article. Says that carbon frames are shit and carbon wheels are great. Absolute garbage on both counts

Ahhh, the young. My first MTB still had 8mm nut/bolts to pinch the cables and 14mm to clamp the saddle rails IIRC. Stem was still an expander, 6mm hex.

First *road* bike was about 50% imperial and 50% metric… needed something like 9 and 11/16th" cone spanners and a 14mm bolt to hold the crank on. Once i’d removed the 1/2″ cotter held on with a 5/16 nut, then the 1/2″ bolt to adjust the expander wedge in the stem, and the 32mm nuts for the headset too… ah. Such joy.

BMX pretty much standardised the 5mm (I think, maybe 6mm) allen key for the whole bike a long time ago. I wonder if it lasted? Probably, because BMX is smarter than this side of the bike industry. Simplify and do simple well. I wish more BMX people/brands would get into rigid 29er design. Chainstay mounted brakes .. new ISO tests will be helping get rid of those, or at least encoraging them back to a more sensible place for any bike that doesn’t use racks and guards (edit, suspension bikes get a pass if they have pivots there). And even if you do use racks and guards, just adapt them to fit around a better frame / brake layout. Priorities.

I still have a 32mm headset spanner from the 90’s for adjusting the somewhat bombproof XT cartridge headset…don’t make em like they used to etc etc..

+100. And bike brands or events teaming up with car companies. F the car industry.

High Quality carbon rims are available from reputable Chinese OEM’s for $150. A lot of what you’re paying for from a Western brand is the warranty support when you smash it on a rock (apart from DT Swiss). Carbon rims definitely make sense on a road bike but I’ll stick with aluminium for mountain biking.

Two of my bikes still do have the cranks held on by 8mm hex bolts! Square taper rocks. Although, to be fair, Shimano BB external bearings seem to last a lot longer these days.

“and just CBA to try to understand Fox etc"

Is Rhythm, Performance, Performance Elite and Factory really that difficult to get ones head around?!

I would agree that Torx bolts need to get in the sea – they’re a PITA compared to a (decent) allen key/head. Star fangled nuts are barbaric too, while saddle rail clamps are the devil’s work.

But you kinda see the point. What part of a fork/ shock used for MTBing conveys “rhythm" to you? Surely you want the opposite of rhythmic suspension – you want “pillow" suspension

Fox’s fork line-up is ridiculously easy to understand compared to the array of different forks that RS offer.

I can have a Lyrik with various levels of damping poshness (which they keep changing the names of), or a Yari which uses the same chassis and has more basic damping… but hang on, now they do a Psylo, where does that sit? And there’s a 35 as well – that looks pretty similar but I’ve no idea what’s inside it.

I’m not particularly a Fox fan, but at least they don’t make a “bad" fork. Just got a secondhand bike with a 38 Performance and it’s comparable to the Zeb Ultimate I was used to riding.