A few weeks ago there was the announcement that Pipedream Cycles had been bought by Route Assembly. Who or what is Route Assembly and what do they plan to do with Pipedream Cycles? I caught up with new owner Ian Byrne for some more information on his plans.

We started with some background on what Route Assembly is.

We started Route up a little over two years ago now, and for some reason I decided to do it just as we had a child, so it was great fun! I’ve been in the industry since I’ve was 14, racing for mountain bike teams and kind of just within the industry. Before COVID, we started a conversation with Scottish Enterprise about how our production works probably isn’t hugely sustainable. The idea was to kind of recreate what they have in Europe and France and that kind of thing, in the UK, because, you know, we’re an island – manufacturing closer to customers makes sense.

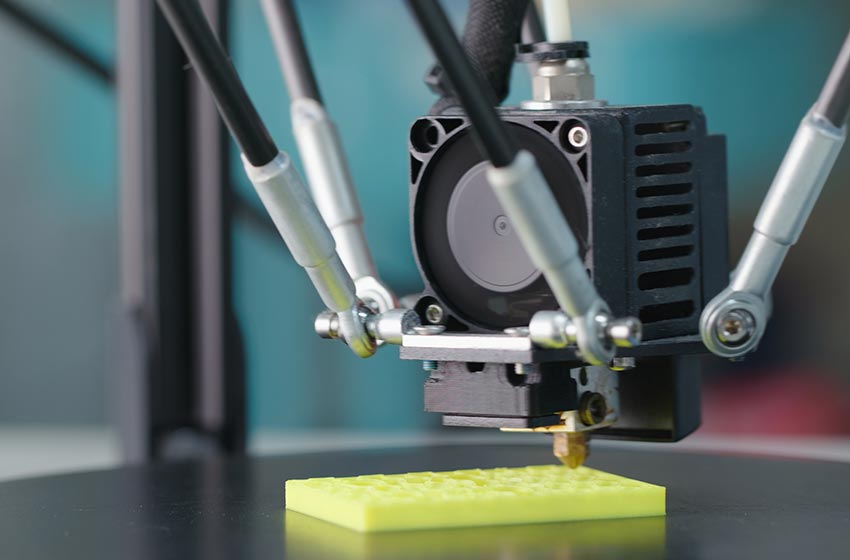

And so we started Route Assembly, to do that. We started some 3D printing projects and we did some test printing of full frames, we’ve done small parts, we’ve worked out our processes on a lot of that. We do assembly projects for a lot of government contracts. So that basically just offers services within the industry.

Latest Singletrack Merch

Buying and wearing our sustainable merch is another great way to support Singletrack

But the overall goal is to bring as much manufacturing as we can back to the UK at different levels. Mid to high end stuff, really. The lower end is very hard to do in comparison to China, obviously. But when you talk mid to high end, it’s very possible. And that’s our overall goal in Route Assembly.

Through a combination of in-house services and partner companies, Route Assembly is trying to create that same concentration of knowledge, skills and capacity that exists elsewhere. It’s the ‘one stop shop’ goal that I’ve previously heard others say is so prevalent in places like Taiwan. If you’re trying to manufacture in the UK, you end up having to source a product designer in one place, a 3D printer in another, a machinist here, a welder there… all that takes a lot of time, plus extra coordination and effort as you make sure each separate entity in the chain fully understands the requirements.

We’ve got a couple of different areas that we deal with, companies that we deal with…. we’re in the middle of a couple of acquisitions to combine it. Once we start to do that, it means that we can cost effectively manage it by hitting capacity fairly easy.

I think a lot of manufacturing issues when it comes to cost is down to capacity. You can see that with a lot of the Asian factories where they’re offering to do production runs for no money down, paying for it when you’re pulling off your stock. There’s really good deals to be had out there. But that’s because factories that aren’t running at capacity cost a lot of money, because you can’t necessarily run on less people. Our goal is to hit a point where when we offer it to other people, we’re already covered.

Overall, we will move the charity, Route Assembly, Pipedream and the other acquisition that we’re just finalising, all down to the Borders, hopefully closer to Innerleithen – and that gives us a base for everything.

They’re currently based in Glenrothes, where the Bike Works charity they help run is a key part of their mission. Ian explains how refurbished and recycled bikes fits into their model.

Nearly everything we do is kind of based around circular manufacturing: it’s like, how do we reduce the carbon costs and the actual costs to make it as carbon neutral as possible and as cost effective as possible. Everything we do, we try to keep in a circular loop, so we always had a bike remanufacturing side in the vision.

But Bike Works itself was closing down. And we saw it and thought ‘Well, that’s the shame, the type of community we’re in really needs that support.’ And so when that was closing down, we thought we could probably do something. So we stepped in and revitalised it and started kind of doing kind of kids’ access programs, general community projects. How Bike Works works, is we have the store in the Kingdom Shopping Centre. We get refurbished bikes that that start under £25. But if someone can’t afford them, we just give bikes away. I think we’ve given away maybe about 700-800 bikes in the past year and a half. We collect them from the recycling yards, Police Scotland, universities. We collect them from all over Fife. We refurbish them and we either give them away or sell them at quite a cost effective price within the community. That’s Bike Works.

So we do that, and we just use the kind of production side of what we do to get parts cheaper, put the labour in better. We use our marketing team to do it, we kind of we use our staff as a kind of donation for the charity. And then the charity actually employs people as well. It’s all about kind of getting everything into the community and using the industry knowledge. How I view it is, in the bike industry, we often want the third sector to deal with what’s left over of our industry – the recycling. We just want someone else to do it.

For me, that’s not really an option, wanting the government to fund the third sector to clean up after us. I think if we build it into our business model that everything we do has that circle, we can start to give a bit more back to the communities that we’re involved in.

So our overall goal is to set up kind of micro factories wherever we have a customer base. And then with any of that, we’ll have a reuse charity.

Having a plan and goals doesn’t stop them getting slightly sidetracked when opportunities arise – which is where Pipedream comes in. They’re starting the process of building Pipedream bikes in the UK

Pipedream is probably more of a brand we just really liked – and the opportunity came up – than it was within the kind of mission, if I’m totally honest. So right now, the first thing we did is our design team started to go and reverse engineer the bikes, to start 3D printing some parts. We’ve started to have some conversations around building in the UK, with a couple of the builders that are already active. Most people know who they are, but they are early conversations. The idea is to bring as much of the production of Pipedream as we can back to the UK within 12 months using a combination of your standard processes and 3D printing.

Basically anything that you go to for Asian manufacturer, we will do. Whether that is procurement, design… A lot of what we do is procurement, design and assembly at the moment. We’re moving into manufacturing. With Pipedream, we’re kind of going through our processes. We are just about to get a Capex grant for 3D printers in-house, and we will start working on that project where we 3D print our parts [and have welding in-house].

We want to get to a point where we’ve reverse engineered all of our yolks, our head tubes, all that kind of stuff. We get them in-house and then we get our welding process here. Essentially, the whole idea of that is to turn it more into a just-in-time project than a massive Capex project.

To get bikes built abroad in small batches, a company generally needs to place the order – and pay – in batches of 10 or 20, and customers often need to pay a deposit. Then, everyone has to wait quite a while for the bikes to be built. By using 3D printing and UK welders, Route Assembly hopes to build bikes to order and on a just-in-time basis, removing that need for large deposits and long waits. Having to have large capital funds to place orders is often difficult for small businesses, and causes the kind of cash flow problems that can cause them to fold – especially if sales drop after you’ve risked an order. On the flip side, individual builders don’t have a marketing team or a design team to help them scale up and make the sales volume needed to pay a wage.

Originally… there was never a plan to acquire other businesses. It was more to offer services to the smaller businesses that started to democratise it away from your massive factories. Now, if we can combine it, you know, anyone can use it. Our business model is essentially we sell time. We have design, we work with procurement. Do you need assembly work done? That’s the time we sell. We generally didn’t hold products.

But Pipedream is a brand that I’ve known for years. You know, the stuff Alan [Finlay – co-founder and rider/designer/former owner] does has always been a different level. But it’s never had a massive team behind it to kind of push the community side of it, to push the communications, that kind of thing. That was just an opportunity for us to get involved with a really, really good British brand and push it. You know, it wasn’t necessarily on the cards – until it was. It wasn’t something we actually targeted. It was they kind of approached us and I really liked it.

Route Assembly is trying something that lots of people have tried to do – or are trying to do. I wondered how they’re funding it, and what Ian thinks means they’re going to succeed.

It was originally funded by me and one of my friends who invested some money at the start. And since then, we’ve just been acquiring contracts. So many people, when we said [what we were doing] sad ‘oh, we’ve tried it, it doesn’t work. We’ve tried it, it doesn’t work.’

And I’m like, ‘OK, but, you know, things have changed.’ And if we look at the problems and try to solve them, maybe we can do it. And so far, we’ve managed.

It’s really just about scaling up now. You know, we’ve spent a couple of years working on our processes. We’ve spent a couple of years refining what we do. And I guess just hustling through it! And now we’re at a point where we can scale up. Pipedream was the next step to that.

The Borders project… we’ll go down there and get your usual business support packages over the next couple of months and scale up to a point where we’re talking about actual good job creation, working within the communities, scaling up the bike re-use side of things. So over the next year, I feel like it should…. well, it’s either going to go really well or it’s not!

They’re attempting what I’ve seen others try before – Islabikes tried something similar before Brexit. Stanton too, were trying to produce bikes at scale in the UK. I wondered if the landscape has changed from when they were trying this – and struggling?

I think there was quite a few people in the industry, pre COVID, talking about moving and changing. But it was a much slower burn. But I think the amount of supply line issues that people were hit with during COVID probably highlighted more to people that we need to look at alternatives.

And I think the other thing is when you talk about manufacturing technologies, they’ve come on – in terms of 3D printing at least – it’s come on so drastically in the past couple of years. That’s something that just wasn’t possible four or five years ago. It’s now possible, things are becoming more cost effective. The machines are coming down by hundreds of thousands of pounds. The speed that they can operate and the tolerances within what they do is coming down drastically. The technology is there now. It’s a case of us learning how to utilise it. Rght now, you can 3D print a full frame in titanium. It takes a lot of time, but you can do it. It’s not even the cost, it’s the time that stops that being totally viable. But things are speeding up.

I think in some ways, it’s whether you hit the right time. And I don’t know whether we have, necessarily. But, I think as we move on, the landscape has changed so much that people are at least open to the possibility of doing it slightly differently.

It’s really hard [in the bike industry] because you’ve got quite small companies trying to forecast sales in the way much larger companies do. And bikes are expensive, so your Capex involvement is huge. I think COVID kind of proved that – everybody tried to maximise their sales by ordering as much as they could. And what actually ended up happening is most people ended up with so much stock that they probably couldn’t afford when sales were depressed.

I think a lot of people either learned lessons or disappeared during that process. On a kind of upside to that, I think at the end of it, we’re probably going to have a much stronger industry when we come out of where we’re at. The people who survive will have learned a lot of lessons and probably learned how to be much more agile. And the ones that didn’t, you know, it’s a shame, but there’s a little bit less competition there. But that being said – we’ve got the car industry having a serious push coming into the e-bike side of things. And they do things right. They do things efficiently. They’ve got massive teams. It is a little bit different to how we’re used to playing. And, Pipedream is very different to that side of it. But with e-bikes, the car industry is a real danger, I think, if we don’t learn how to operate similarly.

So what does all this mean for prospective purchasers of Pipedream bikes? From a consumer’s perspective, what will they see in the immediate and then longer future?

I’d say over the first year, we’re not going to see any drastic change in terms of where anything’s produced. You know, Alan’s already got his factories, he’s already got that. Right now, it’s about negotiating the deals and getting actual stock held. The first thing we did was order 50 or 60 titanium frames, so they’ve gone straight into production already.

We’re doing the same with the steel, the Steel Cirrus S6. We’ve started to talk to builders around the UK about how quickly can we do this? So we’ll see stock rolling off in the UK pretty quickly on that. And then the MOXIE, we’ll probably do a titanium run after a while. And we’ll restock on the Alice’s after that. We have good stock of the MOXIE, so they’re not an urgent thing.

One of the other things we’ll probably start to do is kind of limited edition runs in partnership with UK-based paint shops and things like that, where we’ll do a couple of custom paint jobs, limited 1 to 50 or 1 to 20 or whatever they want to do. Just some funky looking stuff just to change it up a little bit.

So I guess the main change people will see is better stock lines within the next kind of 12 months. In the background, we’ll be working on the reverse engineering and what we can do here as just in time.

What we won’t do, is if it’s going to affect quality, or the price drastically, is to manufacture here. We’re not going to do that. They’re a good price point for what they are, and people like that. I don’t think people want to be paying an extra £400 quid for a steel frame just because it’s done here. But… absorbing some of that into the margins rather pushing the price up just to allow that…I think if we can sell enough volume of something we can take a hit on it. We’re not looking to make insane money on something just because we can.

But get in touch. If we get enough demand for one of the bikes ahead of the others, we’ll produce that ahead of what we’ve got in our head or historically the sales say people want. If more people say, ‘Well, we need Alice’s now’, that’s what we’ll do. I know the community are going to be worried because they all know Alan – they’re all very into how it was. The last thing we want to do is move away from that. It’s very much what we want to do now is know what the community wants from the brand and then try and move it to that.