We Are One makes their bikes and components in Kamloops, Canada. The Hope of Kamloops, perhaps? Their onsite manufacturing lets them prototype things quickly, which led to the slightly unexpected position of them having a UCI DH team this year, with local lad Jon Mozell and experienced racer Mark Wallace racing their bike. Engineer Ben Markwick took a minute to explain to us a bit more about what We Are One is up to with this prototype modular DH bike.

So, you said you were making a downhill bike to test the parts and then you ended up with a team?!

Yeah! So when we started, we just wanted to have a test platform for all of our downhill products and really try and maybe break into that market. So we made a couple downhill bikes to get under the feet of some local riders and then we were approached by Stereo Racing to kind of maybe get something going there. And that sort of led us to getting a UCI downhill team!

What parts have you got on this bike that are downhill specific that you’re testing?

Latest Singletrack Merch

Buying and wearing our sustainable merch is another great way to support Singletrack

We’ve got some prototype parts on here. We’ve got a prototype direct mount stem and the prototype downhill bar. So there’s some specific shapes, some shape-specific stuff that we’ve been working on specifically for compressive stress and trying to lower the compressive stress on the handlebar to change the failure modes. And then we’ve also got some downhill laminate wheels right now that we’re testing out. And I believe that’s sort of it for the moment.

And then you’ve got this modular frame as well?

Yeah, so we kind of wanted to do something that the guys could change up as they needed, right, so to get them more in tune and to also give us information about the bike. We’re new to the downhill space, we’re new to the downhill geometry, so for us it made the most sense to come up with just a carbon bike because we already had the moulds for a lot of stuff, and make it extremely modular. So we’ve got flip chips and different linkages and all sorts of stuff that the guys can change so that they can tweak their leverage ratios, tweak their rear centers, tweak their bottom bracket heights and find out what works for them specifically – and then we can take that information in the future and use it for whatever we decide to use it for. It just helps us get a better understanding of what the top level riders need, and what they like, and what works best for them. It’s also shown us quite a few little things that we didn’t know prior to this because once you get these kinds of guys going three times faster than anybody in our shop can ride and riding really hard it starts to show some unique… flaws in certain parts so it’s been a really good learning experience.

Give us some examples then?!

I can’t really get too deep into that! But yeah just some areas on the bike that we were like oh yeah we can totally… like just do it this way and ended up having to kind of backpedal a little bit, but that’s good that’s part of the learning experience, right?

Right. So that’s quite a substantial down tube mount/interface thing going on in there, so tell us a bit about that?

We had kind of toyed with the idea of like lug designs or… what was the most rapid prototype thing that we could do, right? And because we manufacture we can turn around a mould in a day, a couple of days, right? Or, well, it’s a little bit over exaggeration, I suppose, but we can turn stuff around pretty quickly. So for us, it was just easiest to make a midsection of the bike, cut a mould for that tool, and just go from there. So what that’s done for us is it’s just like, okay, well, what’s the easiest way to mount the shock? And we just decided to bond an aluminium piece that we can manufacture really quickly, which allows us to get that modularity. And then we’ve put some bolts through there as just a secondary safety feature if anything were to happen. That has also shown some interesting results and the guys seem to really like it, so we’re pretty pleased with that.

So do you think that placement is going stay in the same place? Are you gonna be shifting it up and down the down tube as well?

So the way that this is mounted now, it can’t move up or down so if we did have to change it likely would be with those flip chips and those other linkage things. So I’m not quite sure where they’re currently landing especially because we are just about to start the downhill series, so we’ll find out probably in the next couple months here what they really would like to change where they want things to sit, but I think they found a pretty comfortable spot. So I don’t think we’re going to need to move that too far if anything at all.

And what about the suspension layout design here? Is this an adapted one or is it totally your own? What’s the deal here?

We have our designer, Vlad, who kind of came up with this. I’m not super, super familiar with his exact work. He’s kind of our little wizard that we have in the back corner! But yeah, I think it’s sort of still just a similar four bar situation to what we have on the Arrival. It’s just like a modified version of that. Tuned specifically for higher pace, higher impact stuff. He’s got a lot of experience on a lot of different bikes and he’s got a wealth of knowledge, a little book in his head of just all the numbers that he likes and what works best for him so he kind of just pulls it out of the hat and he’s just really good at it.

And if he told you all he knows, then he wouldn’t have a job anymore!

That’s exactly it. Yeah, exactly it! So yeah, he’s our special guy and we love him to bits. But yeah, definitely a wizard! Yeah, one thing that’s actually interesting too, is we’ve done some tube in tube cable routing here, which we had never done in the past. So this was also an exercise in manufacturing on like a larger scale for us. So just in terms of how would you go about doing tube in tube or like what kind of cable clipping, new ideas for that. So we’ve got some 3D printed. carbon reinforced plastic, which is pretty cool. One of our engineers there spent a lot of time getting that all dialled in, so it was really exciting to see that come out. You can just kind of feed the cables through and they work really nicely.

Nice. And all the different modular components, are they CNC’d or 3D printed or mixed?

They are all CNC’d and then anodised as well. Because we have a machine shop with three separate CNC’s, we can pretty quickly turn stuff around. We’ve actually had that a few times, like when the teams first got the bikes they said the initial link was set up more for our style of riding at Cam :oops and when they got on it yhey were like, oh, it’s a little too short. So the first thing we did was just spin up another set of links and send them out in literally a day. So it’s pretty nice to be able to do that.

So does the team have goals for the season then? Or is it just ‘get out there’?

I think obviously every racer’s goal is to do really, really well and potentially hit the podium. And I think that they have some good pace and I think that they have the ability to potentially get on a podium. I know Mark’s goal is probably to do that I would assume. But yeah I think for now it’s just to like get out there and just see what the bike can do, what they can do with the bike and what we can learn from it. That’s kind of our big our big thing.

Nice, thank you very much!

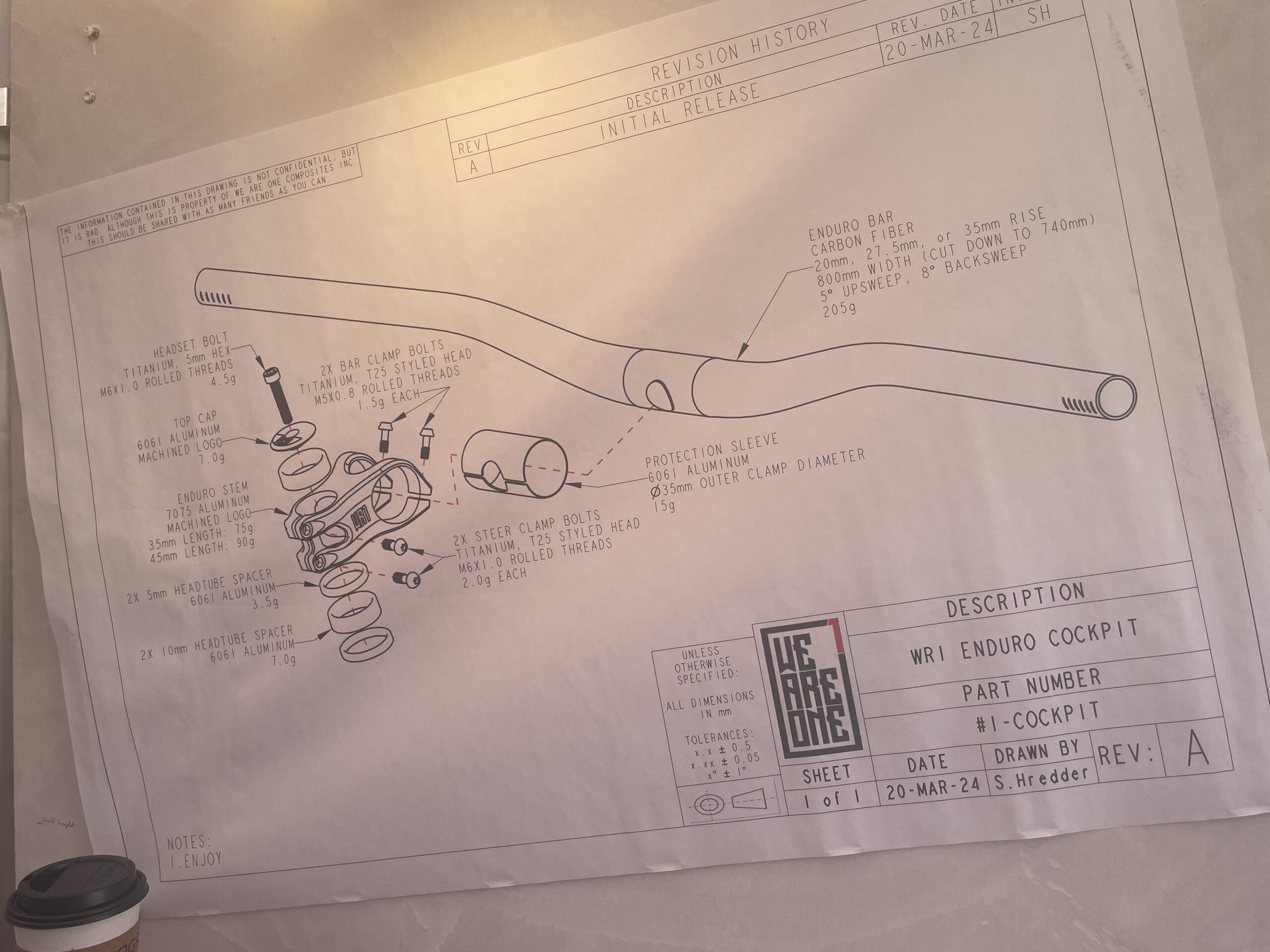

As well as the DH bike, We Are One had a new stem and handlebars to show. Previously, they’ve only sold their bar and stem as a set, because their bars didn’t fit with all stems. The addition of the collar – plus a few graphics changes – means that their bar now runs with any 35mm stem. It’s also 40g lighter thanks to some changes to the laminate used.

The stem gets an update too, with some increased lateral stiffness, and new anodised colour.

MEMBERs’ Features

all the Members only

online features →

Premier

Partners

Our Premier Partners are businesses that support Singletrack by partnering with us to offer great deals to our members. We are fussy about who joins this group so you should check them out.