Steve Chapman talks to the man who makes your suspension work better than when it left the factory.

Words Steve Chapman photography Sarah Barratt

I’ve been harbouring a secret for a long time and I feel like I want to get it off my chest: I very rarely give my suspension a second thought. I mean, I’m glad I’ve got it – it makes rough stuff smooth, it gets me out of a lot of sketchy situations when talent runs out (often), but it’s just there. Now I’m sure we all know we’re meant to do stuff with our suspension – lower leg service fairly often, full service less often, but still fairly regularly – but, honestly I forget about it, and as long as it sort of works I just carry on in an ignorance is bliss kind of way…

James (Jim) Williams, owner of J-Tech Suspension is the opposite to me: he thinks about suspension a lot. So much so, in 2010 he set up a company to focus solely on suspension. Starting in a shed on his mum and dad’s farm, he grew the company steadily over the following years. J-Tech Suspension is based in Shrewsbury in Shropshire, an often overlooked county sandwiched between the big city lights of Birmingham and the green desert of mid-Wales. Shrewsbury is a town with a rich history, and is famously the birthplace of Charles Darwin. I went to visit the team at J-Tech Suspension to find out what motivated Jim to start the business, what they’re up to now, and where they think the evolution of suspension technology and J-Tech is headed…

Latest Singletrack Merch

Buying and wearing our sustainable merch is another great way to support Singletrack

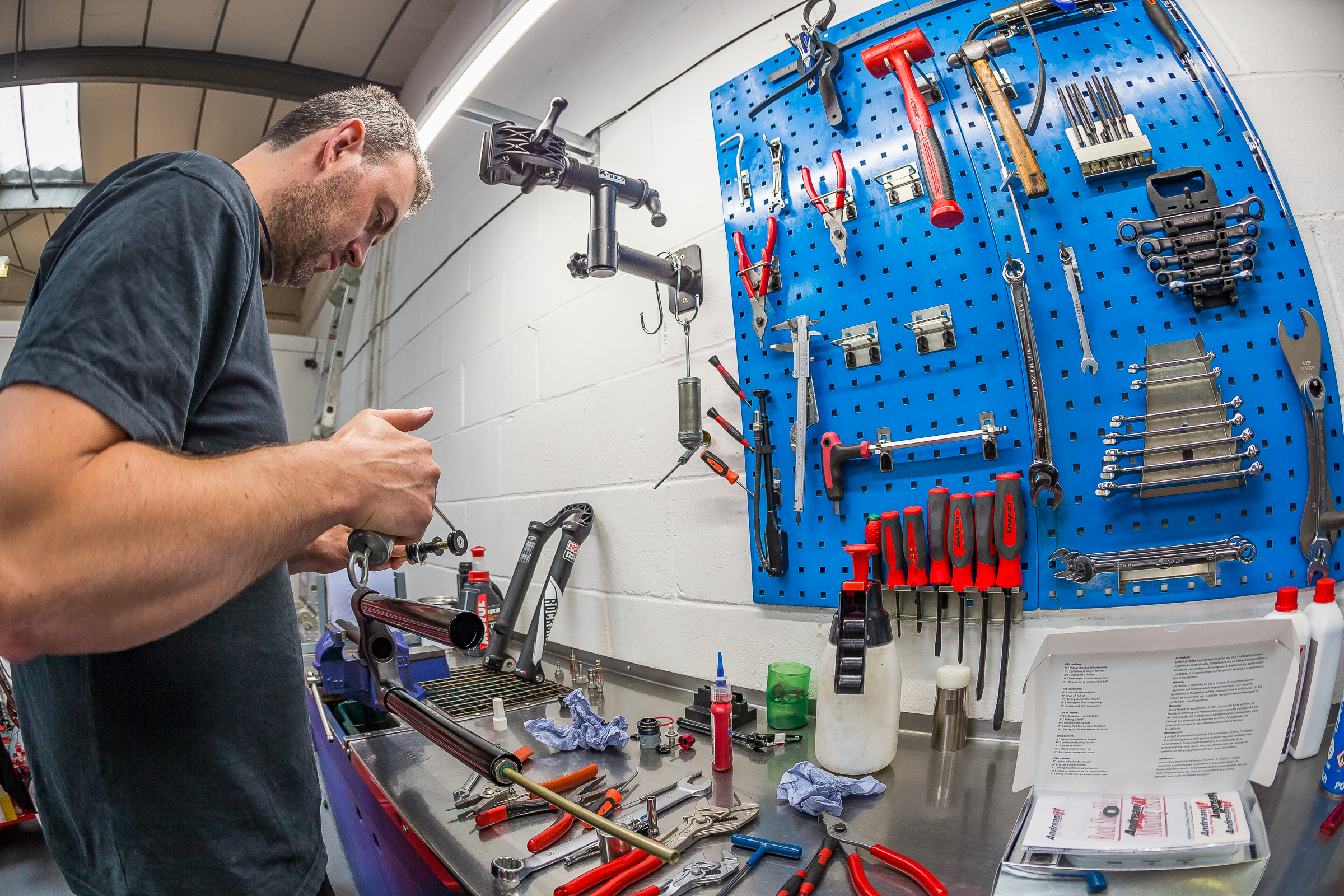

The first thing that strikes you when you go into the workshop at J-Tech is how clean and organised everything is. It’s clear after speaking with Jim for a short while that he’s a stickler for detail and he’s clearly super passionate about the subject of suspension. I ask how he got into all this suspension malarkey?

My first job in the industry was a Saturday job at Pearce Cycles, I was 15 when I started. I was mainly in the workshop, but a little sales too. The workshop was where I wanted to be though… I couldn’t afford anything fancy when I started out and I was really struggling to progress with a basic elastomer and spring fork, so I decided I’d research dampers and went about machining some parts at school in my dinner hours, then assembled and tuned it at home. I kept on developing things from there and tuned every fork and shock I owned.

This lunchtime tinkering is clearly something Jim never got over, as pretty soon after he finished his apprenticeship at Pearce he set about starting J-Tech Suspension.

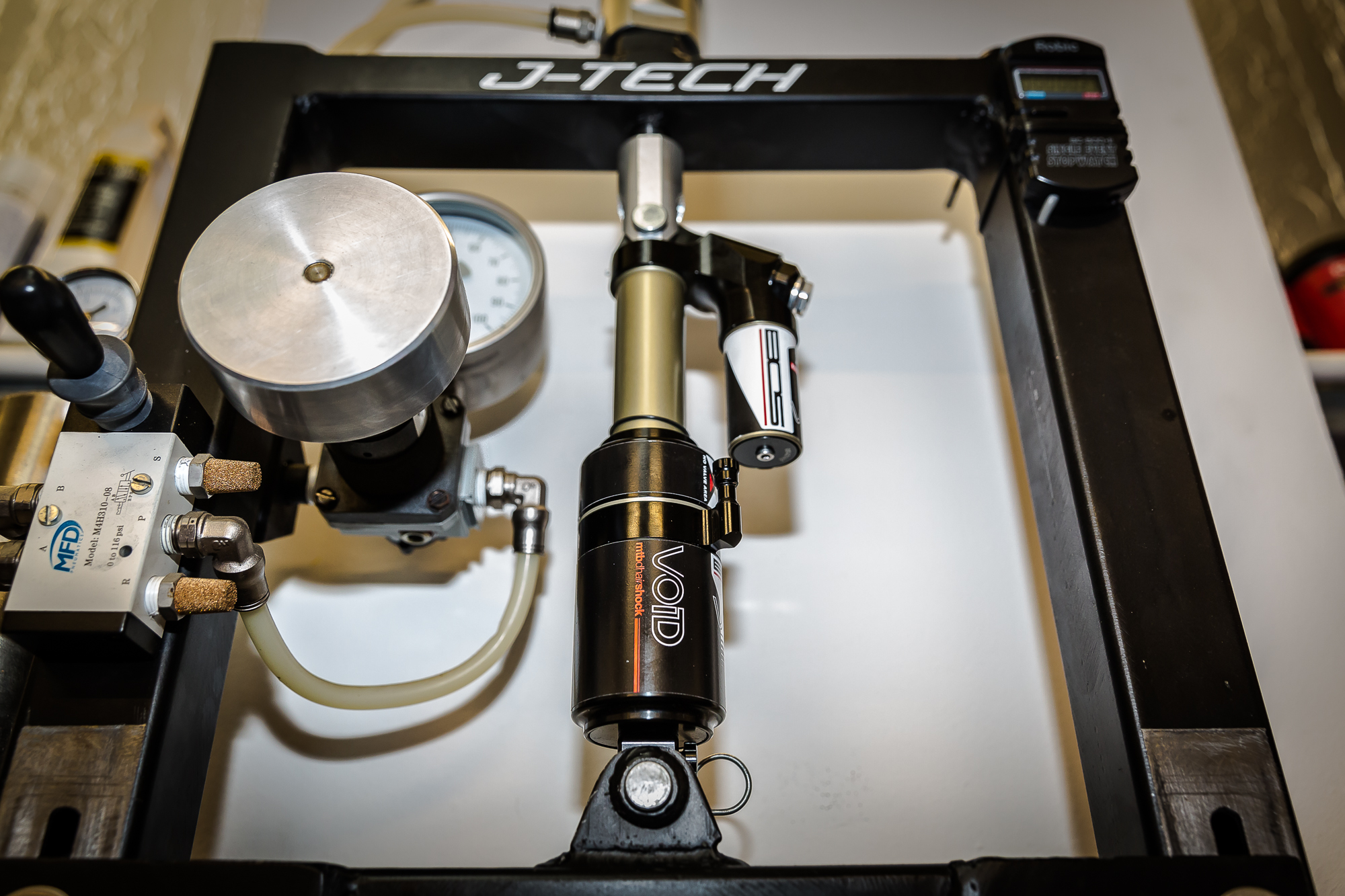

I could see that there was a market for more suspension service/tuning companies in the UK and working on suspension was – is – my favourite thing to do. I knew that data was the key, so I built my own data logger and dyno in order to start taking out any guessing. Very few suspension tuners were actually gathering data at the time and I couldn’t understand why. It’s all the rage now, but we were doing it back in 2010. Still do, only with more fancy equipment!

As well as servicing and tuning suspension, J-Tech also sells a whole slew of suspension-related kit, including shocks, forks, springs, piston kits, etc. I’d read on the J-Tech website that they custom tune every fork and shock they sell, free of charge. Is that really true?

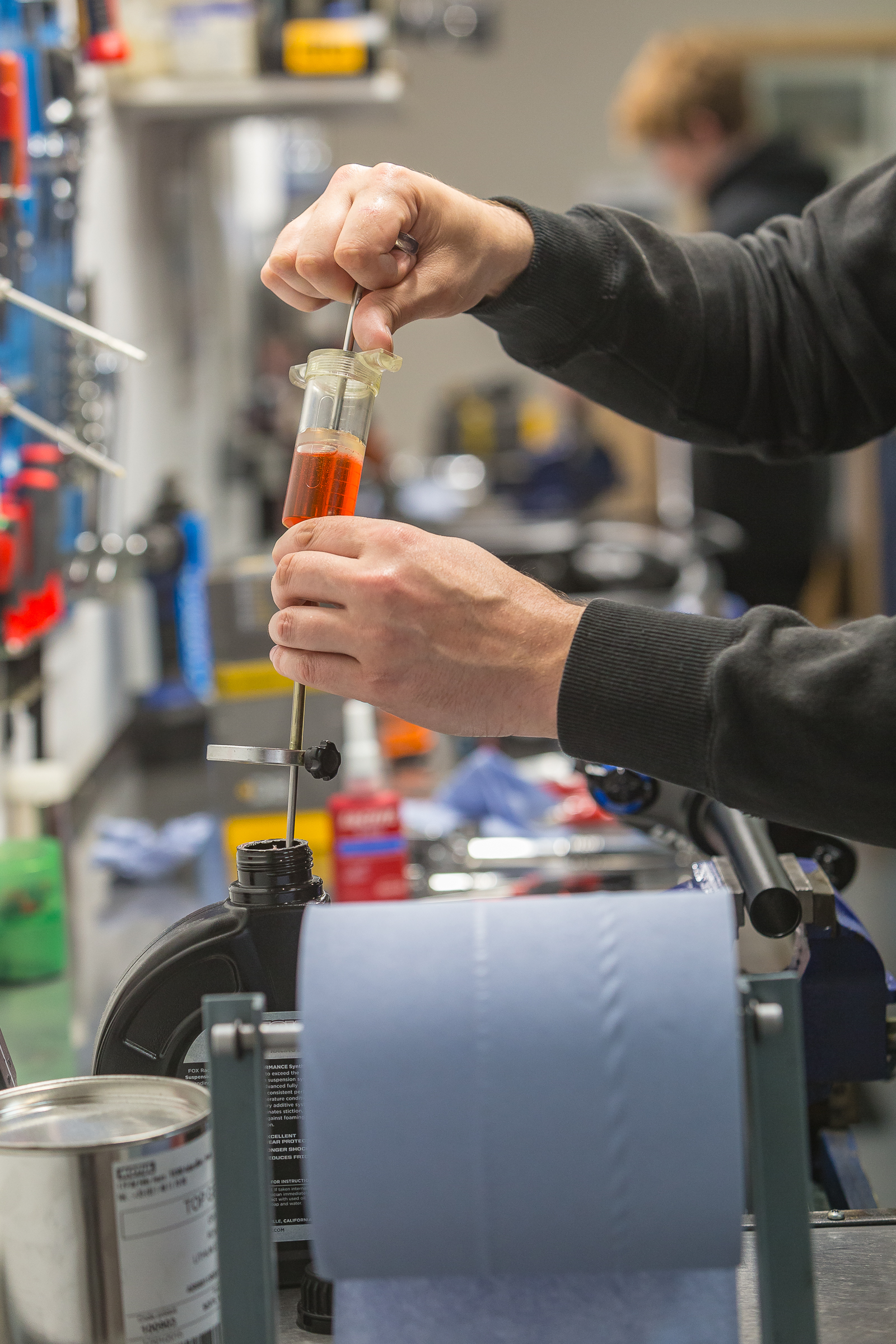

Yes, we do, and to clarify – our custom tuning is not just turning dials, adjusting pressures and fitting tokens! We’re talking about friction reduction, shim stack tuning, low friction additives and higher performance oils – we even make piston ports bigger for some dampers. The biggest issue with off the peg is assembly.

Most brands’ products are assembled in a factory in the Far East, and we’ve seen all sorts of horrors! We see grease where there shouldn’t be and no grease where there should be, incorrect oil volumes, tight bushings, damaged seals and even swarf floating around inside. We also find that although manufacturers claim to cover the majority of riders with their tune, in reality that doesn’t work. There are even some cases where the factory tunes are so bad that we don’t use them for anyone.

We’re not in this for a quick sell, we want to have our customers coming back again and again.

This level of detail and an eye for innovation led Jim to start a new brand at the end of 2022, which he’s called WPS. Under the WPS brand Jim has created a range of suspension tuning products, tools and components aimed at suspension service centres and keen home mechanics. I ask Jim how this came about?

I actually started making tuning parts under the J-Tech Suspension name in 2010–2011, but demand for workshop work and testing meant the time just wasn’t there to continue developing. I’ve always kept it in mind to start again, then with Covid hitting and lead times going crazy, I thought ‘now is the time to start making our own products, in the UK’. We were very busy though, so it took a while to get rolling. There have been a few obstacles to clear on the way (WPS wasn’t actually the first choice of name – a certain F1 racing team had something to say about that).

You can’t just drop that in and not explain! What happened with the F1 racing team?

So, I filed for the trade mark of ‘Williams Suspension’ and after a few weeks (there’s a period of six weeks where anyone can object to your application) I got a letter from Williams F1 Racing’s solicitor advising that they will be challenging the application. So, without wanting to get into a legal battle with them, I scrapped the application. After some thought, the best alternative we could think of was WPS (W1ll1ams Performance Suspension), which we were able to apply for a trade mark on the letter combination and the logo design.

We could have chosen something completely different, of course, but it meant a lot to me to get the family name in there somehow. Especially after losing my Dad not long beforehand.

What a struggle it is to start a new brand, even to name it! I contemplate my own lack of suspension servicing knowledge and wonder what problems they are trying to solve?

Our tuning products will improve performance for any rider, our tools will help any technician, and our parts can help anyone where original parts haven’t been made available… there are lots of flaws we see in products as we’re working on multiple brands of forks and shocks, daily. We’re trying to use all that knowledge to give our customers a better performing product that they can enjoy, hassle free.

What are the most common flaws you see in off-the-shelf products?

Poor assembly/QC. Lack of compression damping seems to be a trend at present too! I think there’s maybe a train of thought that harshness in a fork is down to too much compression damping. This can be true, but most of the time it’s down to too much friction and/or too much rebound damping.

You mentioned data collection earlier, how is all the data that you’ve collected over the years used?

It’s used daily to make calculations for set-up/tuning decisions for each of our customers. It allows us to get an accurate set-up, without having the rider/bike in front of us. It’s not perfect, but we can get very close, as long as the customer has communicated their details accurately, of course. We have damping levels and spring rates we’ve found to work best for rider weights/riding type/ability/bike kinematics that we can then apply to each individual. Along with damping curves, spring curves and friction levels of all the forks and shocks we tune. We can bring all this data together to select the tune and set-up that we think will work best for the application.

If you had to choose a company that’s getting stuff pretty good off the peg, who would it be?

In terms of assembly, Öhlins and EXT are probably the best in the brands we deal with. We also use mainly their factory tunes too (they supply us with data for all the tunes they’ve tested and approved), we just validate those tunes and change the tune for each application, whereas [for] most other brands we have completely new tunes that we have developed ourselves. This can take us a lot of time, but it’s well worth it in the end.

If you had to ride off-the-shelf components, what would make the cut?

Impossible to answer honestly as it would still get onto a workbench when no one was looking, whatever it was!

Coil or air? Why?

Coil! It’s more reliable, more consistent and gives better support. Air is getting much better, and with products like the Vorsprung Secus, you can get a similar spring curve for the support. But, air still heats up and cools down, it can leak and the seals that stop it from leaking create friction. Friction is the devil when it comes to suspension performance.

Of course, the weight of a coil spring does have a negative impact in applications like cross-country racing, where weight is a major factor in the overall performance. But for all-mountain, enduro, bike park, downhill, etc., the performance and reliability benefits far outweigh the extra weight.

Do you think everyone would benefit from having custom-tuned suspension or do you think it’s only the preserve of people who race?

It depends on what you’re starting with, but in general, yes everyone can benefit. However, everything else must be right first. For example, we get customers wanting us to just tune their fork damper, which is great. But if you’ve got tight bushings, misaligned lowers/stanchions, tight air seals, etc., the friction generated will completely negate any performance gains made at the damper.

What are your thoughts on some of the electronic advances in suspension tech, like the Live Valve from Fox or Flight Attendant from RockShox? Do you see that stuff as an inevitable progression or a step too far?

It’s got its place, for sure, and I’m sure it’ll get better too. It suits some applications great, but others not. And we must remember, it’s only really an automatic actuation of your climb switch/LSC adjuster. If the spring or damper doesn’t suit the application, or there are other issues like friction, it’s really pointless. Cars and motorcycles have been using this tech for years and it can work great for certain applications. Öhlins/ are world leaders in this technology, so it’ll be interesting to see if they come out with something. But personally, I feel that a well tuned/set-up suspension package on a well designed frame shouldn’t need this additional control for the type of riding most of us do.

What are your plans for WPS; where do you see it in five years’ time?

We’ve got some exciting plans for 2023 already, in fact, we’ve already been making a start on a large project – hopefully we’ll have some news on that for summer. Otherwise, we’re currently developing more piston kits, more tooling, more parts. We’ll just keep on adding products as we go, trying to focus on those that we can make the biggest impact on. In five years’ time – maybe we’ll have a complete suspension system… CNC machines in-house would be great too!

So there you have it, big plans from J-Tech Suspension/WPS. It was eye-opening seeing all the tech and detail that goes into the tuning and upgrading of folk’s suspension. I’m not an engineer by any stretch of the imagination, but what I do know is that the guys at J-Tech are a safe pair of hands and your suspension or dropper will certainly come back to you feeling a lot better than when you dropped them off.