If you thought the inner tube as daily bit of kit died a half dozen years ago – when tubeless systems really got their act together – then Schwalbe has news for you. The inner tube is alive and well. So well, in fact, that Schwalbe spent the last five years developing a new and better inner tube in the form of ‘Aerothan’.

Inner tubes, grandad? Who still uses them? A fair number of people it seems – not just on road and gravel bikes, but mountain bikers too. Perhaps they never took the leap across to tubeless, or they had a terrible trailside tubeless experience (or several) and vowed never to try tubeless again. With Aerothan, Schwalbe promises the light weight of a latex tube (87g for a 27.5in x 2.3in tube), with durability and near puncture resistance, using ‘thermoplastic polyurethane’ (or TPU) developed specially by German chemists, BASF. And it’s recyclable too.

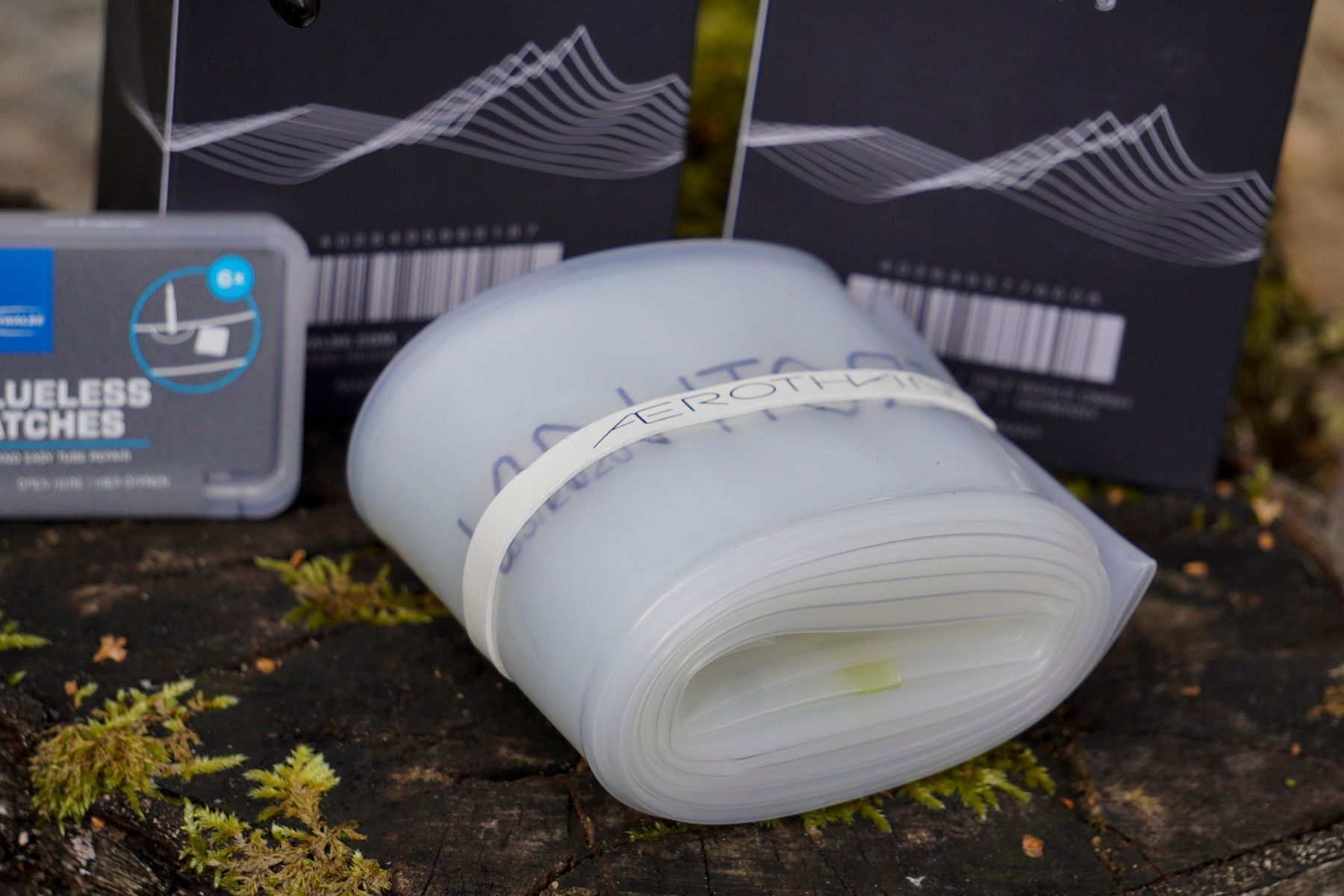

Aerothan is a clear, tough-walled, non-stretchy inner tube. You need to get the right diameter for your wheel and width for your tyre (there are two widths, roughly 2.3in and 2.6in) as there’s no stretching it to fit. The tube is a cylinder with a ‘welded’ join. The thermoplastic valve stem is also welded on. Schwalbe expects riders to run this full time – they’re not really designed to be kept just for emergencies, as Schwalbe reckons that the tube gives a similar ride and can take similar low pressures to running tubeless.

Interestingly, the material isn’t designed to be used with any sealant (which is fair enough, it’s an inner tube) but Schwalbe also advise against the Aerothan tubes coming into contact with latex sealant for too long – which is exactly what would happen if you use one as a repair for a tubeless tyre. Or you’d have to whip the Aerothan tube out when you get home – presumably because the sealant will eventually degrade the tube.

Latest Singletrack Merch

Buying and wearing our sustainable merch is another great way to support Singletrack

Some riders will be very interested to hear about a new, tough and light inner tube, while tubeless fans may not. Especially when they find out that Aerothan tubes will cost nearly £30 a wheel. But hey, what price, progress? Oh, wait, that was tubeless, right? So, what price improved legacy gear?

There’s a whole website ready to answer your questions here: schwalbe.com/aerothan

“The weld is designed to be as low-profile as possible so you won’t feel it.”

… and 14 years old in me starts giggling…

Cheers!

I.

Are there some duplicated paragraphs in there, or is my caffeine just wearing off?

I didn’t see any duplication

I didn’t see any duplication

I didn’t see any duplication

Is this a different coloured Tubolito (I’m too lazy to read the full article)? If so, I’m out (just not up to the job, offroad-wise).

Schwalbe spend 5 years developing an inner tube….

….Singletrackworld spend 5 seconds proof reading

….Singletrackworld spend 5 seconds proof reading

A case of cut and paste and paste?

A case of cut and paste and paste?

What do Schwalbe say are the advantages over tubeless- or are the just for those who find tubeless too much of a faff? What does ‘near puncture resistance’ mean? How do they cope with thorns?

Fixed! I think Chipps has a weird coding gremlin going on, I’ve spotted a couple of these repeated paras recently.

Yes, Tubolito was the first thing which sprung to mind when talking about over priced innertubes…..

Will they beaking them in 26″? If your going for the legacy market, you need to do it properly…

Be just the job for fatbikes.

the tubolitio ones are rubbish. i know of 8 different people that have had one fail (normally at the valve stem) when they have needed to use it as a backup for tubeless.

If these cant be used in a tyre with sealant whats the point?

Tubolito? You toddlers are too young to remember the FOSS tubes. I’ve patched them with a cigarette lighter in a hurry.

https://road.cc/content/news/70707-just-%E2%80%93-foss-inner-tubes

@Keithb

They do them in 54-559 to 62-559 | 81 g

I had one of the previous “reinvented innertubes” that definitely fixed all of the issues of previous attempts to fix all the issues… And it did, for about an hour, then I returned it and the shop admitted that basically everyone that had bought one had returned it.

I’d be less skeptical about that, if this weren’t Schwalbe, the company that’s reinvented the Nobby Nic at least 4 times and has finally made it to “tolerably bad”

I read in another review is that the patches basically don’t. They concluded it was an irreparable tube – which is nice.

I’m still unaware of why you would run this (£30) magic beans inner tube instead of tubeless or ‘traditional’ inner tube?

Is it just more puncture resistant?

I used to run Air-B latex tubes, they were pretty good, this was 20years ago. Is it April 1st already?

Good luck recycling TPU in your council recycling bins