Empire bikes, northern bike makers of the amazing cast AP-1 downhill bike has just announced a new trail bike version. Rather than being fully sand-cast, like the DH bike, this one will be machined from billet aluminium.

Expect to see complete bikes and frames for sale in the summer. We like the look of it – though can imagine that you won’t want to ride it without knee pads… and we’re going to be very interested to see what it weighs. Anyway… on with the official release!

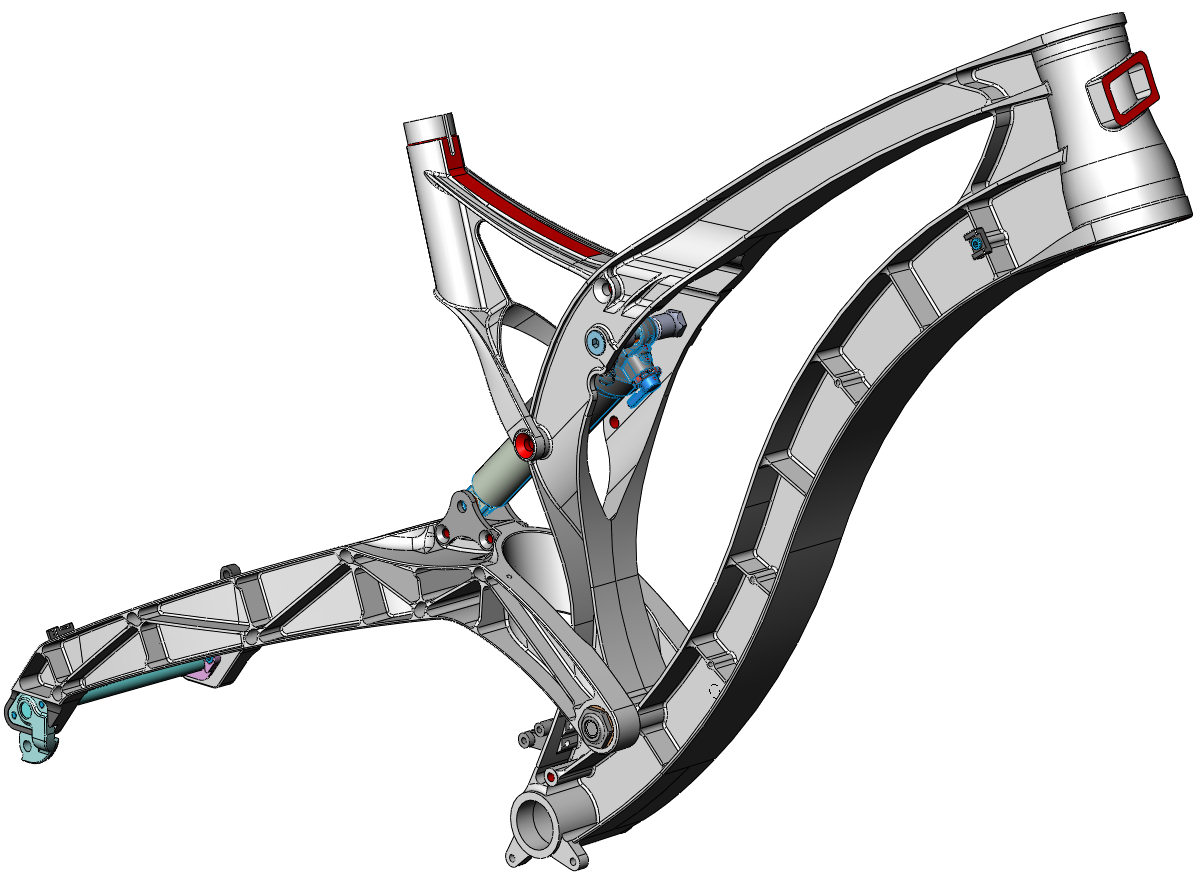

Empire Cycles is proud to announce the birth of the MX-6. This is a six-inch travel, all-mountain, British manufactured product.

It boasts both a machined from solid billet 6082T6 aluminium front end and swing arm, and an aircraft grade cast aluminium seat tower. The DNA of the award-winning AP-1 downhill frame (Red Dot Design Award 2010) can easily be appreciated and all Empire supporters can rest assured that the knowledge and expertise have been passed onto the new arrival.

Latest Singletrack Merch

Buying and wearing our sustainable merch is another great way to support Singletrack

The MX-6 is aimed at the growing enduro market: “basically, the intention is that you can kick the living daylights out of it, up hill and down dale, all day”, says Chris Williams (Empire Cycles owner). Chris adds, “I’ve learned an incredible amount from the AP-1 and wanted to produce a product for the all-day warrior”.

The MX-6 uses the known and loved Empire three-piece structure along with the tried and tested swing arm bearing arrangement and seat tower. As with its big brother, the MX-6 is also without welds. Other features include the latest 2 x 10 drive train from SRAM, Rock Shox suspension, and Avid brakes. Prices will start from around the £4000 mark for a fully built bike and there will be frame-only and exclusive Hope upgrade options. Look out for the MX-6 as a prototype at events through the spring and see it on sale in the summer.

“cast parts don’t have alligned grains”

Erm, I thought aligning the grain structure was the whole point of casting? And it was CNCing that didn’t have any aligned grains?

If niether casting or CNC has aligned grains, what does?

reminds me of the Kirk cast magnesium frame from waaay back in the day…

http://www.retrobike.co.uk/forum/files/kirk_one_853.jpg

forged or drawn parts have an aligned grain structure; like tubes. If empire had wanted to be really clever they could have done positive net forging? where they cast a part into pretty much the shape they want and then forge it to align the grain structure.

I thought the they didn’t want welds is because of the heat affected zone but in reality this is a load of rubbish. Also the idea of the empire was material can be removed where it isn’t needed and put where it is needed. still works out heavier than a simple monocoque like a 224.

The idea is different, just not very well thought out. In my opinion i hasten to add.

“I’ve heard that there is quite a high failure rate with the DH bike version of this…”

Could you cite a source for this?

yeah its cited in a pier approved journal article….. He is right though the first bunch did crack around the seat tower (i think?? (the i think referring to where they cracked not if they cracked))

just checked the Empire site – it was posted on 31 March … could it be an April fool?

Alex 222 I have one of the first batch of the empires frame no. 5 I think. Ridden it for 4 yrs without any issues with cracking which is different to what could be said to 2 oranges, an intense, turner, santacruz, sinister and planet x I have owned, which all cracked at welds/ CNC sections.

Best bike I have owned. even if its 2lbs heavier than an orange 224. (before I ride obviously as all the mud that collects in the frame when I ride it takes it to about the same weight as belgium, mountain bikes with mud on it who would have thought it eh, I suppose the car park of glentress is pretty dry)

heard about this a month or so ago… local lad up here represents Empire…… made reference to my Helius AM being PX’d agianst it….possibly…….!

…’Bravo Empire. Looks mentally ace. I think it’s brilliant that people continue to push limits in so many different ways’…

Oh you’ll be pushing limits alright….esp with the extra mud…perhaps that’s the secret! Progressive resistance training?

…..turner prize for sure, will look the bee’s knees in tate modern & the CAD office….Let’s celebrate, black turtle-necks & titanium specs all round….mine’s a tomato juice

Actually, now that I’m looking at it again: can anyone else see Giger?

RudiBoy, just wondering why you take an 8″ downhill bike to Glentress?

BTW, I think it looks awesome. Just not at all sure about this CNC manufacturing. At all… That design but a monocoque and you’d have a mini Honda DH bike with normal gears. Now that would be sweet.

I’ve drooled over the AP-1 and I like this too.

This is a purely product-design ‘object’/aesthetic response though, without regard for cost, etc etc.

To me it’s like art – you like what you like, and often the questions of an object’s value are kinda pointless.

Hey – at least it’s not a BMW/Porsche branded bike….

dave boy wonder….It was meant to be a pish take for the people who were whinging about getting there bike dirty and the extra weight of all the mud.

http://www.pinkbike.com/photo/5747620/

I like this.

So do I.

rudi boy; well what can i say you are obviously a happy customer. i still don’t like it or the ap 1. don’t know how they are going to produce it for such a accessible price.

Looks like my proflex oz made from meccano , rather than carbon.

similar head , ‘tubeset , seat mast , pivot point, swing arm and shock position

https://lh5.googleusercontent.com/_Ro4hpNyJ6E4/TW4w4JPC6DI/AAAAAAAAEHI/vKcNG5NG3C4/s800/IMG_6769.JPG

Nice idea, it’s good to test the limits of materials. But yes, many drawbacks (mud, money, injury potential?). I thought a 2 piece frame with the webbing on the inside would be an improvement, then realised it’s a square tube with extra material inside!

I’d like to see lugged frames revisited for Al and Ti, it’d be quite dapper.