Empire bikes, northern bike makers of the amazing cast AP-1 downhill bike has just announced a new trail bike version. Rather than being fully sand-cast, like the DH bike, this one will be machined from billet aluminium.

Expect to see complete bikes and frames for sale in the summer. We like the look of it – though can imagine that you won’t want to ride it without knee pads… and we’re going to be very interested to see what it weighs. Anyway… on with the official release!

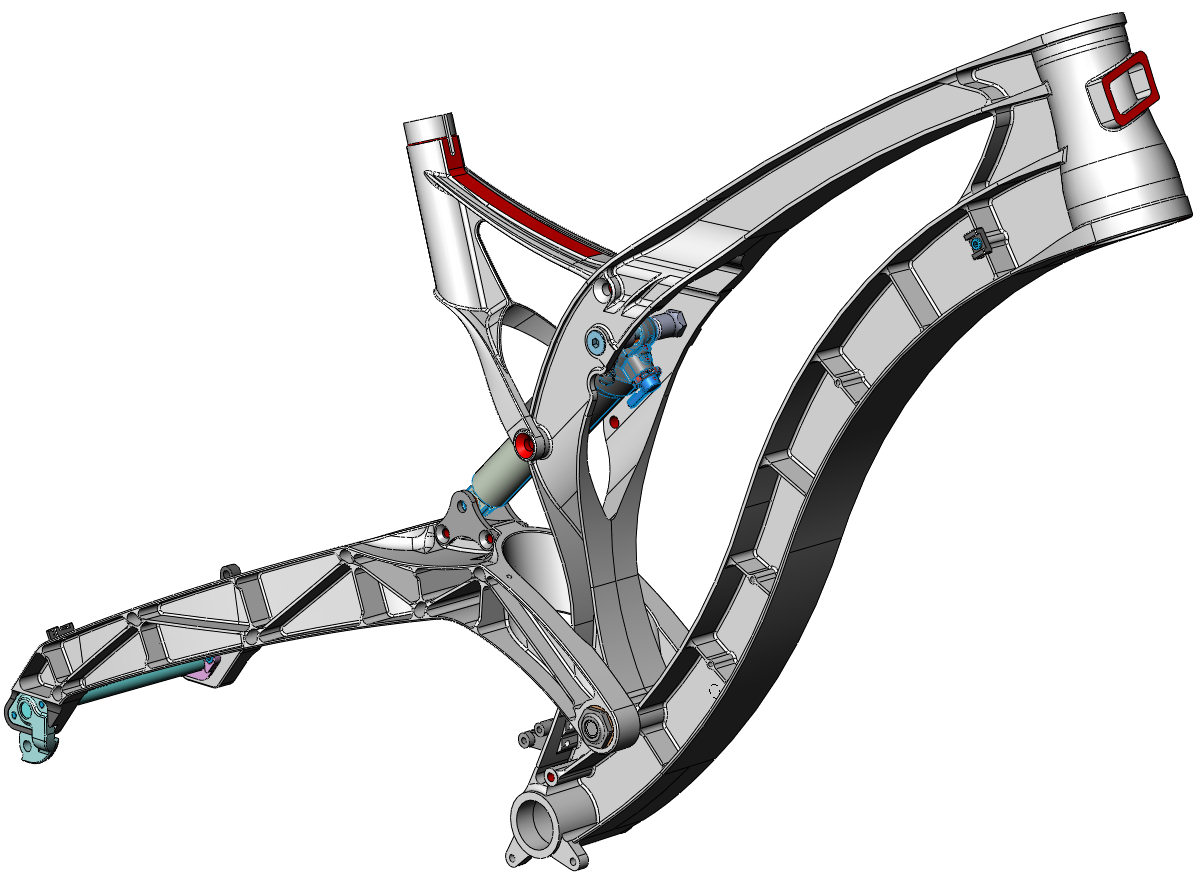

Empire Cycles is proud to announce the birth of the MX-6. This is a six-inch travel, all-mountain, British manufactured product.

It boasts both a machined from solid billet 6082T6 aluminium front end and swing arm, and an aircraft grade cast aluminium seat tower. The DNA of the award-winning AP-1 downhill frame (Red Dot Design Award 2010) can easily be appreciated and all Empire supporters can rest assured that the knowledge and expertise have been passed onto the new arrival.

Latest Singletrack Merch

Buying and wearing our sustainable merch is another great way to support Singletrack

The MX-6 is aimed at the growing enduro market: “basically, the intention is that you can kick the living daylights out of it, up hill and down dale, all day”, says Chris Williams (Empire Cycles owner). Chris adds, “I’ve learned an incredible amount from the AP-1 and wanted to produce a product for the all-day warrior”.

The MX-6 uses the known and loved Empire three-piece structure along with the tried and tested swing arm bearing arrangement and seat tower. As with its big brother, the MX-6 is also without welds. Other features include the latest 2 x 10 drive train from SRAM, Rock Shox suspension, and Avid brakes. Prices will start from around the £4000 mark for a fully built bike and there will be frame-only and exclusive Hope upgrade options. Look out for the MX-6 as a prototype at events through the spring and see it on sale in the summer.

What was the original design objective of the AP-1, i.e. what did a cast bike achieve over a welded one? It seems odd that they invested such a huge amount of time and money into developing casting technology for the AP-1, only to not then carry it over to this bike.

The articles in Dirt on the AP-1 really made emphasised just how much of an extraordinary acheivement the AP-1 was in terms of being cast, and how they’d had to overcome huge technical hurdles to make it successful. So why not carry it over?

It seems like the design objective is now just to make a bike without welds, which may have some virtue, but not in the guise that they’ve designed here for the mud clogging reasons.

ive seen the predecessor to this in the flesh at a dh demo day (an xc version)

they had a proto of this machine all done up for an mx show somewhere, i think it was entirely cast but with cnc bits, was about 30lbs irrc built up which for a tough am bike is fine in my book

http://www.singletrackworld.com/forum/topic/empire-bikes-castcnc-xc-bike

the stw haterz massif slagged it off then too

Ming, it doesn’t matter if its the best riding bike in the world, if its going to clog up with mud, weigh more than a standard tubed/monocoque frame and cost a grand more than a top spec Five etc then whats the point?

Like I said, solution to a non-existant problem.

DaveyBoyWonder does have a point.

The answer is that sometimes you have to push the boundaries just for the heck of it in order to learn something you didn’t expect to learn. It’s basically what Honda set out to do with the RN01.

The world would be terribly dull if we all rode around on things that give the best VFM.

Quantifying the V is the hard bit.

Bravo Empire. Looks mentally ace. I think it’s brilliant that people continue to push limits in so many different ways.

Hater?

I’m not sure about that, because I love the lines and the sheer audacity of it. That said, practical considerations are an issue for me, so I would look elsewhere unless I were wealthy enough to afford to throw a few grand away on a piece of object d’ art, in which case I’d buy one immediately.

Great to see someone do something other than weld/glue/braze a pile of tubes together.

I suspect they are not casting it at this stage as they want to do a small scale run of frames to start with and then once the design is proven they might be willing to stump up the cash for the tooling.

I rather like the look of it, but then I like my old style Heckler, Nicolais, etc. which all have a rather industrial/utilitarian/USSR era military equipment styling to them.

I hope it works, or they are at least are given the chance to find out, it is good to have people trying different things. Different doesn’t have to be wrong and change isn’t necessarily bad (I should probably tell the Daily Mail this too). I imagine that bit of aluminium and plastic hanging off the back of your bike that helps to change the gears was probably thought of as “flimsy, ugly, overly complex or cheating, solution-to-a-problem-that doesn’t-exist” by many at the time. But that seems to have (mostly) caught on. And I imagine Campags over engineered QR was though of in much the same way but that and all it’s evolved forms (Maxle, RWS, etc) still seem to be about. Even if it doesn’t work lessons will be learned and knowledge progressed. With the exception of oppressive religions and the current government I can’t think of many people who would deem that to be a bad thing. Lots of things don’t really solve current problems, but they do open up new avenues that were either non-existent or inaccessible (e.g. the internet). These “solutions” often create more problems or bump into the next frontier. But such is progress and is why I’m able to write this on a laptop ready to be zapped across to a server in deepest, darkest Todmorden and then available to the world rather than daubing it of a cave wall in my own faeces and hoping that one of the other grunting inhabitants of my proto-tribe shambled past to see.

I, for one, may actually wait and see how it works before passing comment. Yes, it may collect mud in it’s current guise but I doubt it will be that much considering which bits of my bike accumulate mud (under down tube, fork brace and bottom bracket) imagine that will be taken on board and something done if it really is a problem. As far as mud goes I would be more worried about the shock, but then I imagine they will put a shroud over it for that reason. And it may be like falling on a cookie cutter but I can’t remember the last crash I had where the frame made serious contact with me. Bar ends, brake levers, saddle, wheels and pedals but not the frame. I doubt they were planning on having razor sharp edges to it anyway.

DBW, its different, if it works as well as it’s counterparts and I had the money I’d consider it.

My current full susser fills up with mud and gains weight on wet rides, so I tend to take the singlespeed out when it’s bad.

It may well be an evolutionary dead end but then again maybe not.

to be honest i think the whole empire concept is pants, cast parts don’t have alligned grains. To counter the effect that the unaligned grains structure material has to be added, hence an ap 1 is much heavier than a 224 which is a similer bike.

I can’t see them being able to even break even selling whole bikes that are fully cnc’d for 4k, frame only maybe. the tooling costs will be astronomical. the cnc frame will have a similar issue as the cast frame unaligned grain structure hence extra material must be added for strength.

I’m not even going to say it looks good though. ming, it could make an onion cry. though best of luck to the guy he seems to be doing okay selling his current iteration of ugly bikes.

not quite sure how its ‘pushing the envelope’ either? I’m pretty sure honda were testing existing dampers etc, just thought they could get useful data from dh.

Anybody else think it odd to have vertical gussets on the down “Tube” making boxes instead of ones at 45 degree to make triangles?

One advantage of this manufacturing process is that you can have material where the FEA requires it.

Agree with all the comments about mud traps……………though it would be very easy to incorporate small tapped holes on the main frame so a thin covering could be bonded and screwed on.

Nothing wrong with exploring new ideas, I think its p

From my engineering armchair I thought the limiting factor for aluminium tubes is crush strength so I imagine this sort of structure might offer weight savings, especially as the billet will have better strength properties.

I wish I could try one. Snowy? Take a fatbike. Muddy? A singlespeed. Rocky and down? Empire perhaps 🙂

You could clingfilm it for a muddy race?

Seriously, I think it looks ace and its good to see people doing things differently just because they can. For such a bunch of nichemeithers I am a little suprised this is not embraced in the same way that other far out or just ‘non-normal’ designs are on here.

They seem to have chosen the right alloy though for doing it (6086-T6). If you are going to go down taht route it ticks the relevant boxes. Time will tell I guess.

maybe they’re getting a dollop of money from aerospace industries to push fixtureless machining further? They can do fea and find where more material needs to go but fea is by no means an absolute and a problem like this would have to be massively over simplified meshing that would take some serious processing power; would like to know how they’ve done that. Plus all those corners will act as stress raisers so may have a negative affect on the frames strength.

Unless the mud can fly up and then turn sideways into the frame I don’t think the mud issue is going to be as bad as people think. Most Australians hated the design of the Sydney Opera house before it was built and became world famous.

Good on you Empire, would love to have a go on one! Loving the looks.

I’ve heard that there is quite a high failure rate with the DH bike version of this…