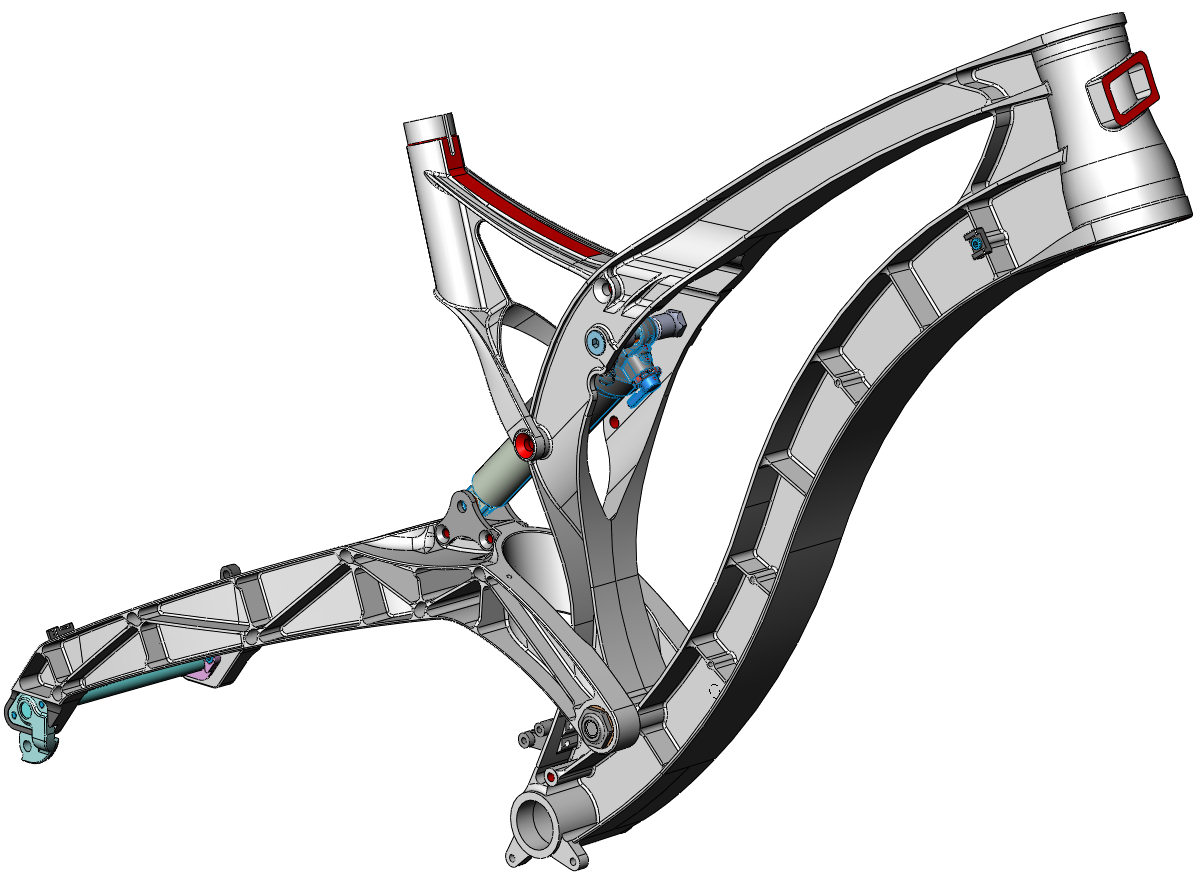

Empire bikes, northern bike makers of the amazing cast AP-1 downhill bike has just announced a new trail bike version. Rather than being fully sand-cast, like the DH bike, this one will be machined from billet aluminium.

Expect to see complete bikes and frames for sale in the summer. We like the look of it – though can imagine that you won’t want to ride it without knee pads… and we’re going to be very interested to see what it weighs. Anyway… on with the official release!

Empire Cycles is proud to announce the birth of the MX-6. This is a six-inch travel, all-mountain, British manufactured product.

It boasts both a machined from solid billet 6082T6 aluminium front end and swing arm, and an aircraft grade cast aluminium seat tower. The DNA of the award-winning AP-1 downhill frame (Red Dot Design Award 2010) can easily be appreciated and all Empire supporters can rest assured that the knowledge and expertise have been passed onto the new arrival.

Latest Singletrack Merch

Buying and wearing our sustainable merch is another great way to support Singletrack

The MX-6 is aimed at the growing enduro market: “basically, the intention is that you can kick the living daylights out of it, up hill and down dale, all day”, says Chris Williams (Empire Cycles owner). Chris adds, “I’ve learned an incredible amount from the AP-1 and wanted to produce a product for the all-day warrior”.

The MX-6 uses the known and loved Empire three-piece structure along with the tried and tested swing arm bearing arrangement and seat tower. As with its big brother, the MX-6 is also without welds. Other features include the latest 2 x 10 drive train from SRAM, Rock Shox suspension, and Avid brakes. Prices will start from around the £4000 mark for a fully built bike and there will be frame-only and exclusive Hope upgrade options. Look out for the MX-6 as a prototype at events through the spring and see it on sale in the summer.

Does anyone proof read these press releases? Avid ‘breaks’?

Seat mast brackets look incredibly fragile???

looks like a bugger to clean

Nice.

i really hope it works for them, but it looks expenses to make, and on a wet day in Wales i think its going to get heavier as it fill up with mud, teflon coating anyone?

looks like it needs a G-Boxx integrated into it…

it’ll suit Hope components as a piece of artistically over-the-top machining.

How about a carbon fibre skin over its “skeleton” to keep it clean. In fact, the carbon could be thick enough to add some strength. To the point it wouldn’t need the skeleton…

I hope they’ve got a good swarf recycling system!

I like things like this though – great to see people showing passion and bucking trends.

Does it remind anyone of the old Mtn. Cycle San Andreas?

(a good thing IMO, I hasten to add)

“basically, the intention is that you can kick the living daylights out of it, up hill and down dale, all day”

I do that anyway on my current bike?

hardly for the masses at 4k!

i like it

These guys need to hire an engineer instead of a CAD jockey with no idea.

I’m with Dang. 1/2 and hours ride in UK mud this thing will weigh twice as much with all those mud pockets.

Cue Mazda jokes unless they change the name?

Different for the sake of being different?

Looks gash.

AlexSimon – already done with the old Cannondale Raven and that wasn’t exacty the most successful bike of all time. Seems to be a solution to a problem that doesnt’t exist.

I really want to like this…

However my problems with it are threefold:

Firstly, how much stiffer and lighter than a conventional tube structure is this frame going to be?

Secondly, it’s going to be expensive to produce being mostly CNC’d from a solid chunk of aluminium, which seems a tad unnecessary to me, unless I’m missing the point?

Thirdly, it looks like it’s going to wind up weighing a substantial amount more at the end of a muddy ride thanks to so many open mud traps. Hardly the most practical design out there.

As I said, I really want to like this frame. It’s innovative and a fresh approach to design, but I can’t help thinking that a similarly priced Whyte 146 (or even an Orange Five / Santa Cruz Bullit) is going to leave you feeling fresher and with less maintenence after an all day ride.

tubes work

have done since the birth of the bicycle

no need for fancy over engineering

keeps it simples

I work with CNC’d parts every day and as a piece of engineering to admire it will potentially be impressive. I’d love to hang one on the wall. As a bicycle it’ll be useless.

It’ll clog up with mud.

In a fall it will probably cause the rider more injury than a tubular frame.

Tubes lend themselves to strong light construction where as this girder style frame will be pretty lardy and it does look like a cad designer has planned it. A few areas look a bit flexible.

There is a reason why every manufacturer from mass producers to boutique makers have stuck with tubular style frames.

I like,

lets see how it rides before we start casting stones, oh I forgot I’m on STW;

“bag of pebbles a Paand!”

“Two cobbles for 3 quid!”

“Chunks of granite a fiver!”

are there any women in the crowd?