![]() You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

You don't need to be an 'investor' to invest in Singletrack: 6 days left: 95% of target - Find out more

Hello Brewerists!

I got a few bits of gear and a Coopers IPA kit for my birthday. Got it all mixed and fermenting earlier this week and I'm now just waiting for the gravity to stabilise.

I work for a malt distilling company so I'm pretty knowledgable on the science of what's going on but need to learn the skills of doing it with home kit and also what boiling and hops is all about?!

Two questions from me:

1. I have a 23 litre fermenter but have just bought kit to do an all grain recipe and I'd like to keep it to 10 litres so I can experiment. Is it an issue NOT to fill the fermenter to the top? My logic - CO2 is more dense than air so will quickly displace the air and will perform as normal . . . thoughts?

2. How long do most people wait between mashing in and boiling? My logic would say that by boiling all of your first wort (or all your wort if not sparging) you'll be killing the enzymes and won't be converting all your carbohydrates, particularly dextrins so you're missing out on sugars. Maybe efficiency at this level isn't an issue in home brew?

Thanks and I'll keep you posted on my bottling and maturation of the Coopers kit . . . not expecting too much 😉 Just order ingredients for a St Austell Tribute 🙂

welcome to the fold teacake!

1. sticking 10 litres into a 23 litre FV for primary won't be too problematic since as you've said the Co2 will blanket the beer. Bigger problem if you were transferring it into an FV with loads of headspace for secondary etc. I wouldn't worry.

2. mash for an hour (although, I've read that conversion actually takes place in the first few minutes, so not quite sure why we mash for a whole hour, but it's pretty standard to do so). Then go straight from the end of your mash/sparge to boil temp. Even with no attempt to improve efficiency, it's easy enough to hit upwards of 70% efficiency using even BIAB, so at this level we're talking the difference of a few pence for each jump up in overall efficiency. I never worry about it.

Had the boiler in my flat replaced today.

Now have a whole new, empty cupboard where my water tanks used to be.

The copper hot water tank would actually have made a really good kettle!

Too big to handle brewing like that in a flat.

Plan is to make it into a brewery.

End goal is to have pressurised kegs in fridges feeding taps through the wall on the right (which is my kitchen)

[img]  ?oh=a82f07f3b1caff81f42152022d334e63&oe=5592B0AA&__gda__=1432255957_a1a02b02ed470224f597db0cd3a96d1c[/img]

?oh=a82f07f3b1caff81f42152022d334e63&oe=5592B0AA&__gda__=1432255957_a1a02b02ed470224f597db0cd3a96d1c[/img]

Well after a few kits since Christmas I did my first all grain brew yesterday.

The whole thing has escalated very quickly and thanks to the joy of Ebay "Collection Only" bargains I have far too many barrels and FV's already!

I picked my full AG kit for £70, only been used a couple of times and in excellent condition.

I got this recipe off the interweb, it's a St Peters Golden Ale clone, one of my favorites, so I hope it works out well.

Pale malt 4000g

Wheat malt 100g

Crystal malt 220g

Challenger hops 7.6%AA 34g @ 90 mins

Golding hops 4.6%AA 20g @ 10 mins

Golding hops 20g @ 0 mins

OG 1.048

Estimated FG: 1.011

Estimated ABV: 4.7%

Colour: 18 EBC

Bitterness: 30 IBU

Final Volume 23l

I came up a bit short with 20l at a OG 1046 so I need to tweak a few things.

It's hard work compared to using kits mind!

The beautiful smelling hops just before they went in the boiler.

Sacling question: I have a recipe I want to do (Abbeydale Moonshine), but using the Massive Brewery kit. The recipe I have is for nearly 22l so I need to scale it down. How do I do this? Is it jsut scaling all ingredients down realtively? Or is it not (as I think it might well be)?

Recipe is:

Type: All Grain

Date: 23/12/2007

Batch Size: 19.00 L

Brewer: Troy H

Boil Size: 21.75 L

Boil Time: 60 min

E Brewhouse Efficiency: 75.00

Ingredients

Amount Item Type % or IBU

3.50 kg Pale Malt, Maris Otter (Thomas Fawcett) (5.9 EBC) Grain 100.00 %

16.00 gm Williamette [5.50 %] (Dry Hop 3 days)

16.00 gm Williamette [5.50 %] (30 min) Hops 9.1 IBU

16.00 gm Williamette [5.50 %] (25 min) Hops 8.2 IBU

16.00 gm Williamette [5.50 %] (20 min) Hops 7.2 IBU 1

Pkgs American Ale II (Wyeast Labs #1272) [Starter 2 L] Yeast-Ale

Beer Profile

Est Original Gravity: 1.044 SG

Measured Original Gravity: 1.010 SG

Est Final Gravity: 1.011 SG

Estimated Alcohol by Vol: 4.26 %

Bitterness: 24.5 IBU Calories: 90 cal/l

Est Color: 8.4 EBC

Color: Color

Mash ProfileCarbonation and Storage

Carbonation Type: Kegged (Corn Sugar)

Volumes of CO2: 1.8

Pressure/Weight: 30.9 gm

Carbonation Used: - Keg/Bottling

Temperature: 15.6 C

Age for: 28.0 days

Storage Temperature: 11.1 C

I came up a bit short with 20l at a OG 1046 so I need to tweak a few things.

does your boiler have a tap? how much liquid does it take before starting to come out of the tap? work that out and then scale your brews up to include that dead space and then you'll get the amount you're aiming for. Or thereabouts

For example, I know my boiler has 4 litres dead space below the tap so if I want to do a 23L brew, I scale it up to 27L and then at the end of the boil, I [i]should[/i] get 23L in the fermenter.

If I get less but stronger then I know I need to add some water back in - best using bottled water for that. Or I shrug my shoulders and agree to have a bit less but at a stronger ABV

The recipe I have is for nearly 22l so I need to scale it down. How do I do this? Is it jsut scaling all ingredients down realtively?

pretty much, yes.

I use Brewmate software, available free from www.brewmate.net - set your batch size to whatever your recipe says, then enter the ingredients as in the recipe. Then adjust the volume down accordingly, and the software will do it all for you.

simples

4L deadspace, all that lovely beer going to waste 🙂 Couldn't be doing with that 🙂

well most of it is goop from the hops, and the hot-break protein, and stuff, so I prefer to leave it where it is 😉

hmm this looks good John. Thanks. Downloaded and playing...but I can't get the IBU anything near. How do I put the hops into the software as per the recipe?

The fermentables go I the top half of the screen, hops in the middle third, and others eg Irish moss at the bottom.

Hops can go in as leaf or pellet - select leaf.

You can set up the AA values of the hops and the sugar content of the grains in the setup section. Also in setup you an choose all grain, extract or BIAB. I use BIAB.

There's a Brew Day tab that tells you how much liquid you'll need. And a Timers tab

There are also loads of recipes on. Brewmate.net. Some duplication though

To play with the OG and IBUs you can toggle Grain Mode iirc. Using my iPad at the mo so I don't have immediate access to Brewmate but I'll update tomorrow at the latest

Thanks John, I can get a IBU of 26.4 (aiming for 24.5). Also colour is out at 10.2 (aiming for 8.4). Wonder if it's the preset alpha of the williamette hops that is causing this difference.

Hello brewers

First brew on the go at the moment just a question about temperature if it's not in correct temp range what actually will or won't happen regarding fermenting? Thanks in advance, brew on the go is a coopers IPA!

Alpha acid content will vary from one pack of hops to the next. Should be on the label. Won't make any difference to the colour though, that's in your specialty grains.

To modify your IBUs, reduce or increase the quantity of your bittering hop I.e the one that boils the longest. Don't mess with the aroma hops though 🙂

To reduce the colour, reduce the quantity of the darker grains and increase the quantity of the paler grains to match, or vice versa to darken it

You should be able to modify alpha acids, colours and sugar content in the Settings tab.

remember Brewmate is a US program so their defaults may differ from ours, so to be as accurate as possible, try to update the grain and hop settings for each pack. If you can be bothered 😉

brocks, re temperature- if it's lower than recommended it will still ferment, just not as fast. If it's above recommended, you could get some 'off' flavours e.g Apple, banana. Better a bit too cool than a bit too warm

Word of warning re the coopers IPA - it takes about three months of bottle conditioning to begin to be anywhere near its best.

Brocks - John is spot on about banana flavours with high temp fermentation.

I've just started opening my first brew (a Coopers IPA as well!) and while it is fine to drink the banana nose and flavour is, interesting! I'll store them away and hope it improves. 3 months noted on the calendar.

Next up for me is a St Austell Tribute copy. I've been messing with Beersmith - will keep you posted.

Friend of mine from Holland shared a glorious Tripel he home brewed at the end of last year. That'll be my third brew sorted then . . .

Question about BIAB bag - I found some viola (curtain backing material) - do I really need to sew it into a bag or could I just stuff it in the pot and throw the grain inside, then hoof the whole lot out after mashing is complete?

Happy brewing!

Yes you could, but I find a bag keeps it all neat while you run a couple of litres of hot water through it for a final sparge before adding that back into the boil

Goddam predictive text 🙁

First all grain mash done! Lovely smell in the kitchen. Was a little ahead in SG pre-boil but the weakness of my hob meant I ended up a little bit back (I'll need to tweak the equipment profile).

Biggest issue i faced - scaling the grist and water but NOT scaling the hops. Target was 32, Beersmith estimates 65! Waweee!

So now we wait and see what we get out of it. Itching to get going on another mash at the weekend so might get ordering . . .

Little update.

Got a new setup - 24l pot that works on my induction hob.

started mashing in the oven as it has a 65c temperature setting that seems very accurate.

Also shelved out my brewery cupboard:

[img]  [/img]

[/img]

Got a couple of batches of Arrogant Bastard on the go in there. One with US-05 yeast and a second with S-04.

Eventually will clear out a little more space in the bottom and put in a keg fridge, some gas and regulators and run 2 lines through the wall into the kitchen and have taps.

Need to perfect my brewing first, hence the small batches. Have enough fermenters to have 5 on the go at once so can keep experimenting.

demo day tomorrow at my LHBS.

Chocolate Stout or Caragold (Citra/Cascade hoppy golden ale) ?

Did my third AG brew yesterday. It was a Brew Dog Punk IPA clone from The Malt Miller.

They do [url= http://www.themaltmiller.co.uk/index.php?_a=viewCat&catId=9 ]AG kits.[/url]Great service from them as well.

The Chinook hops smelt fantastic. Well looking forward to this one.

I've got 3 brews fermenting at the moment.

Might try a single hop/single malt brew next time, this [url= http://beersmithrecipes.com/viewrecipe/253585/smash-mo-citra-mo-problems ]IPA looks interesting.[/url]

Any Calderdale residents or those passing through Hebden Bridge might be interested to know Drink? - the bottle shop on Market St owned by Hebden Bridge Brew Co/Bridestones is doing a homebrew competition soon where the winner can do a full brew with them at the brewery.

Chocolates stout it was. Took a couple of samples " here are two I made earlier", went down very well

Got a few bottles of my St Austell tribute copy/cock-up (2.5 times to much hops!). It doesn't come across as bonkers bitter as I expected - Beersmith says 65 IBUs. I bottled 2 litres and have dry hopped the remaining 6L with 10g Cascade and will bottle that this weekend.

[img]  ?_subject_uid=34494413&w=AAA1aZSTJ1nEJ6GoCQUY9FvUOoI6-DecX0zylnLSOLJLHw[/img]

?_subject_uid=34494413&w=AAA1aZSTJ1nEJ6GoCQUY9FvUOoI6-DecX0zylnLSOLJLHw[/img]

It's quite a hazy beer which I guess must be due to the amount of hops I've thrown at this recipe?!

Going to brew on Friday night with the remaining malt I have. I've got a Maris Otter/Munich mix and will add Cascade. Going to try for an American IPA style.

I've now started splitting all batches into 2, so that I can do "experiments" and fine tune beers while being able to do a side by side comparison.

e.g. playing around with different yeasts, dry hopping rates, length of time in primary, secondary v no secondary, spice and other additions etc.

Should be quite fun and really useful being able to open two bottles of beer made from the same wort and pick out the differences that each change makes!

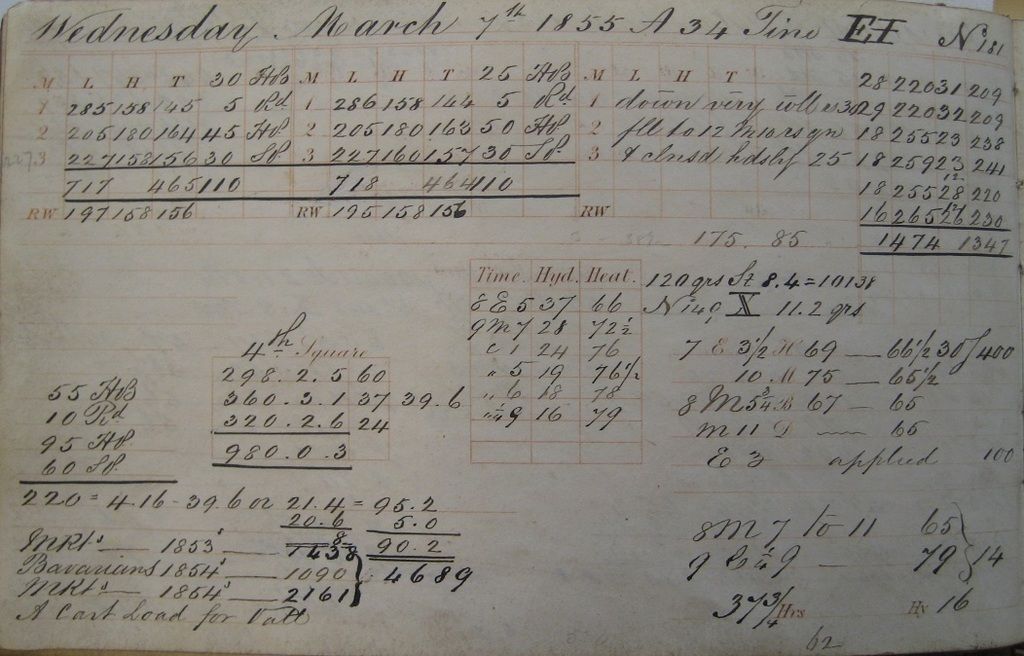

The beer in the fridge is an export india porter. One of my favourite commercial beers is Kernel's EIP, which from a bit of digging around I found out they'd based on Barclay Perkin's recipe from 1855.

I managed to get a look at the original 1855 recipe (see pic below) and after some historical digging around, worked out what the grain bill was. But it didn't seem quite right. I won't write the grain bill here, since it was really fun trying to work it out and I'd hate to spoil the fun for anyone who googles looking for it. If for some reason you do want it, email me!

I emailed Kernel in the hope that they'd be able to cast an eye over my proposed grain bill and let me know if I'd picked it up correctly and the response was utterly brilliant. They gave me a full run down of what they changed in BP's recipe and why and some brilliant advice for putting it together. I didn't think Kernel could go up much higher in my expectations, but they've managed it!

🙂

Nice work PF

In case anyone else is interested my Grainfather has arrived and I have zero time to use it so is for sale, new and unused. There is one person interested but not confirmed. I can let you complete the purchase and get it shipped to you for £600 total, all you owe me is the deposit I paid. Email me if interested - for the moment I am far too busy !

Any tried coffee flavour in their beer?

Brewed a chocolate stout the other day. Thinking I might split the batch and add some coffee to one half.

What's the best way - chuck some coffee beans in?

Grind it first or make espresso and add that to the fermenter.

Ah cool - I'll try that. My pal has a coffee shop round the corner from my flat so I'll get him to make me an espresso.

Did you sell your Grainfather?

Gents (or those close to Edinburgh at least) I just accompanied my newly 18 year old lad to a brew session at Stewart's Brewery in Bilston. Their cRaft beer kitchen lets up to four folk do a 40 litre brew for £180 - with the option to increase the brew to 80l for another £55.

I've done a few kits in my time and thought it was a good birthday a pressie for him as well as seeing how the pros do it. I've been tempted to do a brew from grain/hops but never really knew enough to take the plunge - the guy who ran the session was really good and never stopped talking about what was going on.

First really sunny day and we got to spend the gaps between adding stuff and boils to sample the 20 odd beers on tap in outside.

we go back a week today to bottle the160 or so that's now brewing away! Can't wait.

Decided (against my better judgement - rightly so) to build a website for a friend's business startup.

As it was a pain in the ass, I thought I'd think of the money not as money, but as a treat:

No real financial justification for it or anything, just seemed cool and less of a hassle than my pot.

Took me a little while to put it all together and figure out how it worked.

I got it from the homebrew shop on my street (www.brewstore.co.uk) who kindly gave me grains/hops/yeast for a brew with it.

Did my first brew on it - went great! Very easy, and no mess in the kitchen. Normally I splash so much wort around that I have to do a couple of mopping sessions around after. I have a very small kitchen.

I also got a much greater volume of beer for the same time spent.

This is how much my old brews produced:

[img]  ?oh=f169c923481be96c9c6515dfe610624d&oe=558E8593&__gda__=1434159596_5afe93da94ea3dd3a237aa85cdec6e91[/img]

?oh=f169c923481be96c9c6515dfe610624d&oe=558E8593&__gda__=1434159596_5afe93da94ea3dd3a237aa85cdec6e91[/img]

This time round I almost filled the fermenter.

Efficiency was through the roof as well - 93%!

Recipe was a pale ale. 4.7kg of grains got me 27 litres of wort at 1.047 to boil down.

Overall, an extravagant purchase but a good one. Will be doing another brew this week for my friends' wedding at the end of July.

I also just had these guys delivered:

[img]  [/img]

[/img]

Just need to get some more wee bits and some gas for them and I'm a couple of steps closer to having a bar in my house. My friends' parents are retiring and closing down their hotel so I'm going to see if I can go round and get some bar kit off them.

Excellent! Was it easy enough to clean afterwards?

I've been toying with the grainfather for a while, but I can't seem to pull myself away from building a nice shiny HERMS 3 vessel set up (I like building things so that would be part of the fun).

Good work on the cornies...I'm picking up a chest freezer on Wednesday that can hold 6 🙂

I entered a couple of beers into the London Amateur Brewers comp, which is a big one, and both scored in the top 10%, despite them being beers I was not particularly happy with. I quite like sticking random beers into comps since it's useful to have someone who can detect defects giving an opinion. I know what I like to drink and whether I'm happy with a beer, but my palette isn't sophisticated enough to identify all the undesirable characteristics of a beer.

That Export India Porter I brewed a couple of months ago has turned out to be the best to date.

My friends' parents are retiring and closing down their hotel so I'm going to see if I can go round and get some bar kit off them.

Give me a shout if there are any gas manifold/regulator boards up for grabs! 🙂

Yeah, it's easy to clean - you get some cleaner with it, fill it up with water and use the pump to swoosh it all around everything.

In fact, gonna do another brew today I think

Nice set up there YGH!!! I had my appraisal yesterday and received a "clean bill of health" (his words not mine) - so my bonus is en route . . .

[b]Thought I'd share a bit of learning regarding labels for bottles. [/b]

I've been using [url= http://www.canva.com ]canva.com[/url] to design trendy looking labels in a few mins.

Then I print them off using a colour laser printer, cut to size and use milk to stick them to the bottles. Yes I said milk.

Soak a sponge in milk, use this to wet the back of your label (like your granny used to do with stamps) then stick to bottle. I find this very robust, quick, cheap and easy to clean them off afterwards.

It doesn't smell or discolour either. Magic!

Teacake, you could also try Grotag, who make professional and reusable labels for you. Not particularly expensive either.

I just use liquid chalk pens!

Did another brew with the Grainfather - screwed up though. I wasn't reading the instructions properly and put the grain in the basket before it went in the strike water - causing it to overflow. Had to pump some out and then squash all the grains down to get them in. Didn't get anywhere near my gravities - think the grain was too compressed.

Also tried just chucking the hops in it for the boil. That didn't work out - big mess to clean up and lost some of the wort as it was too hop infested to pump or pour out.

Back to using hop bags!

To be fair, I was trying a beersmith recipe and had wanted to reduce the alcohol content significantly, so in a way it worked out.....

Another brew on tomorrow night - nettle beer!

Nettle beer - ace! There was a nettle based drink being made down in Devon and the poor guy was put out of business because HMRC decided it wasn't a beer so he had to pay extra tax. Sad story.

Peterfile - Grotag, that's not what I was expecting?! Something to do with Dungeons and Dragons style game?!

I presume you mean grogtag - can't get their page to open at present.

What are your thoughts on the Grainfather YGH? Any complaints?

What's doing Brewerists?

I've been brewing like a mad man but tonight will be my first one in 5 weeks as my 2nd son was born 5 weeks ago on Saturday! Naming that wheat beer after him 😉

I think my biggest improvements recently have been adding a ball valve to my mash tun (makes draining it loads easier). I also realised the stone outbuildings are very temperature stable - this has meant I don't need to build a beer fridge just yet, but I do need to choose my beer based on the weather conditions.

I'm starting to tinker a bit with water chemistry to get better bitterness from my beers.

Getting a Belgian Dubbel on tonight. Cocked up the calcs for the first one which was 9.3% instead of 6.5%ish.

What recipes are people enjoying right now. Any new kit on the go?

I've been playing with making yeast starters and think I'll make a little stirplate and evens tart propagating from slants as I see this as a big cost saving (buy a liquid yeast for £6.50 once and get several batches out of it).

Cheers!

Congrats on the new arrival teacake! 🙂

I've had a bit of a building frenzy in the last couple of months. I'd promised myself I wouldn't commit to any "serious" kit until I'd been brewing for a couple of years and that if I was still hooked after that long then it was a safe bet it wouldn't gather dust.

I bought everything in dribs and drabs as I found parts I needed (easier said than done!) and then built it all up in an outbuilding.

the current set up consists of:

Yeast starter/harvesting equipment - build a stir plate and have selection of flasks, centrifuge tubes and other gubbins that allows me to not only hit proper pitching rates, but also to overbuild starters and store yeast, giving me an endless "free" supply of any liquid yeast I buy.

70 litre stainless HLT - with a 3kw LWD element, sightglass, ball valve.

50 litre stainless thermopot mashtun - this thing is amazing. Took a reasonable amount of drilling and angle grinding to convert to bottom drain, but I have zero deadspace and due to its design I lose less than 0.5 degree over a 60 minute mash even when it's only a third full.

70 litre stainless boil kettle - another 3kw LWD element, stainless steel braid filer (build from some engine braiding and stainless fittings), ball vavle etc. This allows me to comfortably brew double batches if needed.

6 keg(!) keezer. This took forever to put together but it is absolutely brilliant. I converted a large chest freezer to accommodate 6 cornies by building a collar to raise the lid. I then added co2 and a full gas management system (got lucky and picked an old coca cola gas management board which is perfect for the job) and put together an STC set up for temp control.

2 fermentation fridges - this was my favourite bit. The outbuilding isn't close to my house and controlling/monitoring the fridges was going to present a problem. Solved that with a Raspberry Pi, Arduino, couple of relays, a Mifi module, dynamicDNS and the excellent brewpi software. I can now control the fridges from my phone wherever I am. I was particularly pleased with this because I had to do all the soldering and software stuff myself, which was new territory. A few hiccups but got there in the end...hugely satisfying!

closed co2 transfers - I put together a little system that allows the direct transfer of beer from the FV to the keg in a completely closed co2 system, meaning the beer is never exposed to oxygen from the moment the yeast is pitched until I drink it.

Oddly enough, I'm actually drinking very little beer these days, probably around 5-7 beers a week, I give most of it away. The cost and effort required for a big batch is so close to that I was used to for small batches that it makes sense to brew more and spread the love amongst friends 🙂

I'm still doing either very early or very late brews. I enjoy getting up at 5am to preheated strike water and being finished up by the time others are waking up!

Flippin' ek! That's a lot of building and a serious set up. A friend runs a brewery and said once you buy stainless FVs then you're in trouble!

How long can you keep one yeast strain going? Do you put them on agar and freeze? How useful is the centrifuge and how do you use it?

My next process improvement will probably be sorting out fermentation temperatures by building a fermentation fridge. Will take your earlier advice on water analysis too.

Same as you - my actual consumption is quite low. I won the local home brew competition which has nice.

Friday's Belgian Dubbel went really well and is fermenting just now.

Upcoming brews: Winter ale, oak infused Wee Heavy, Milk or Oatmeal stout.

Babies are up between 6 and 7am so my brewing needs to be at night but it would be nice to do morning brews. Set a new record of 3 hours from mashing in to closing the FV - biggest bottleneck now is waiting for the wort to start boiling on the kitchen stove!

Flippin' ek! That's a lot of building and a serious set up. A friend runs a brewery and said once you buy stainless FVs then you're in trouble!

It's odd, it worked out cheaper than you'd expect (i'd decided from the outset that if it was likely to cost much more than a grainfather than i'd just buy one of those). I imported the pots directly from the manufacturer in Germany for £140 including delivery, then bought everything else I needed as I was building it. Most of it is just plumbing stuff!

How long can you keep one yeast strain going? Do you put them on agar and freeze? How useful is the centrifuge and how do you use it?

I just use centrifuge tubes for storage rather than an actual centrifuge.

Storing in the fridge you lose around half the viable cells after 3 months, but because you can calculate the decay you can just adjust your starter to account for it, so you could keep the strain going indefinitely. I don't harvest from the FV, simply overbuild a starter and decant the overbuilt cells. Brulosophy has a good guide, although I use a slightly different technique.

I haven't bothered with glycerin and freezing since I've not really got the freezer space at the moment, although it would be nice!

My next process improvement will probably be sorting out fermentation temperatures by building a fermentation fridge. Will take your earlier advice on water analysis too.

Getting your fermentation temps under control will make a huge difference. If you can, build/buy a thermowell (I got a bit of stainless tube and a local engineering company sealed off one end for the price of a beer) and I'm picking up beer temp rather than sticking the probe to the side of the fermenter.

Playing around with temp profiles is really fun too. Raising temps gradually after initial ferm has settled down has helped my beers clear up. I'd recommend picking up a copy of Jamil's "Yeast".

Same as you - my actual consumption is quite low. I won the local home brew competition which has nice.

Mega congrats! That's brilliant work! What beer was it? fancy sharing the recipe?

Friday's Belgian Dubbel went really well and is fermenting just now.

Upcoming brews: Winter ale, oak infused Wee Heavy, Milk or Oatmeal stout.

I'm not sure whether you've read it, but you'd probably enjoy "Radical Brewing" by the sounds of your upcoming brews. Not only is it a really well written and entertaining book, but it has some utterly fantastic sounding beers in it, all of which are a bit old/different/crazy. Definitely my favourite brewing book.

Babies are up between 6 and 7am so my brewing needs to be at night but it would be nice to do morning brews. Set a new record of 3 hours from mashing in to closing the FV - biggest bottleneck now is waiting for the wort to start boiling on the kitchen stove!

Yeah, since moving to the new kit it has been a revelation in terms of getting things up to temp compared to my old stove, but I'm sure I'll miss being in my warm kitchen in my slippers by the time winter comes round 🙂

I don't have the recipe to hand but it was basically one third Munich malt, 2 thirds Pale malt. A sack load of Cascade added 15 mins from the end to get 40 ish IBUs then dry hop for a week with Cascade. West Coast IPA I guess you'd call it?

I'll do the same again soon but using Simcoe for the dry hop (passionfruit - yum).

I presume you are using stainless FVs then? I'm on 15 litre plastic buckets for 10 litre batches. What FVs are you using?

I'm using a 15 litre pot, BIAB and doing two fly sparges with 75C then 80C water. I get good efficiency and a level of faff I am happy with.

Thanks for the book recommendations and the yeast link. I'll get reading. Two books I'm interested in: Mastering Homebrew by Randy Mosher (apparently he has lots of focus on how to design for taste/aroma as opposed to style) and The Art of Fermentation which looks at bread, chorizo, beer and other places fermentation is used and how.

I love using munich in IPAs. I try to avoid crystal since i'm not too keen on anything sweet detracting from the hops.

Simcoe is indeed lovely 🙂

I use plastic "[url= https://www.home-brew-hopshop.co.uk/homebrew-fermenters/litre-carboy-pet-p-1851.html ]Better Bottle[/url]" style carboys for full batches or buckets for small batches, or 5 litre bottles for batches that I split up to experiment on.

Stainless FVs aren't really on the radar at the moment, so expensive for not a huge amount of benefit. I don't mind binning plastic fermenters every now and then. I do quite fancy a conical though...but would settle for plastic.

I never bother with a sparge when doing BIAB, efficiency was around 69% without one which I was fine with, just bumped up the grain bill a bit.

Randy Mosher's stuff is great!

We are using a 50mbar Propane reg at work on our shop casks.

Provides a near perfect .7psi blanket of 70 / 30 and allows serving over several weeks.

Just need a very accurate PRV set and forget at approx 1.5psi to vent any excess secondary feremntation CO2.

Still need a primary reg off the gas bottle, but the propane jobby is fixed , and was £9 from the 'bay.

Currently brewing 5000gals of a very , very hoppy 3.8% . At the moment ( in CTs @ 8 days ) I am worried I might have overdone it and it will be undrinkable . Thing is it could be drunk in 6 weeks time, and will hopefully have massively softened by then

Good work peter file, I'm genuinely impressed with your progress

Thanks Clobber, but it's not that impressive...the wonders of the internet meant I was never truly in new territory since some other poor bugger had always hit the same problems before I did and a solution was only ever a google away.

I did realise a few things along the way...

Q Max Cutters are a gift from the gods,

no drip can get past 10 turns of PTFE tape,

never assume that a cheap chinese relay will be put together correctly by the factory (I wasted 2 evenings thinking my brewpi wiring or coding was wrong before realising the relay was manufactured incorrectly),

neighbours will think you're building a meth lab and will become very curious and uneasy,

a decent cable stripper is worth its weight in gold,

drill slowly with lots of torque and pressure,

John Guest fittings look like they won't work but they do,

a 10" in line extractor is enough to pull the hops back out of your wort 🙂

Peterfile - what temperature sensor do you use for your Arduino and how is your thermowell situated/constructed? I presume it's for your plastic bucket fermenters? Does it go in though the lid?

Keeping my eye out for an old chest freezer as I'd love to be able to hit -1C for cold crashing.

Cheers!

teakcake, you'll want two of [url= http://www.ebay.co.uk/itm/281392057533?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT ]these[/url] for probes.

I bought about 40cm of 7mm inner diameter stainless tubing and had a local engineering company weld one of the ends. It then sits perfectly in the centre hole in a carboy cap like the one below.

I'm using a 23 litre "better bottle", which is basically a PET carboy.

Let me know if you need a hand building/coding the brewpi, since it's still very fresh in my mind. It's easy enough.

Thanks for the info. I'm going to have a go at building a basic Arduino temperature logger first to get a feel for working with it. Then I'll start building the brew pi part and source a freezer!

The better bottle looks good from a hygiene point of view (small neck opening) but how easy are they to clean?

I clean all plastics with a long oxi soak, since I'm always worried about scratching them. I've also got a spray head on my cleaning hose in the outhouse, which delivers a heap of pressure, so it's useful for loosening things up first. You can get a soft brush that is designed for cleaning the inside of plastic carboys, but I've yet to find the need for it.

I followed [url= http://www.homebrewtalk.com/showthread.php?t=466106 ]this DIY guide[/url] for the brewpi.

I've put together the recipe I used for a beer that did well in a recent comp.

EIP

76% Maris Otter

7% each of Brown, Pale Chocolate, Dark Crystal malt

3% black malt

I really like Chinook and Cascade combo with this, seems to work well.

You're shooting for around 60 IBUs, aim for your favourite IPA hop schedule. I used about 2:1 Cascade/Chinook, with 15 IBUs coming from first wort hopping with chinook and the rest are late additions. I also did a great big hop stand.

Dry hopping was at 6g/litre.

Yeast... US 05 is a slightly bizarre choice for this sort of beer, but it seems to work. It doesn't help the malt much, but lets the hops stay a bit more defined. I've tried with with 04 and it just wasn't the same...tasted confused and muddled. Follow whatever temp profile gives you good results with whatever yeast you use. Dry hop for 5-7 days and then cold crash.

I shoot for a 67-68 mash, at around 5.3 pH.

I can give you the water profile I used if you want to dip into balancing your own profile.

This needs a bit of time in the bottle to settle down and come together, I'd say around two months. The hops have dulled a bit, but it's needed to let the malts come together IMO. If you drink much before this it can be a bit harsh.

I currently have some rhubarb wine fermenting away, apple wine this week and a Woodforde's Nelson's Revenge kit next week, should be ready for Christmas.

Just wondering if anyone here aerates their wort and if so how?

As I am syphoning out of the kettle, the wort falls out of the syphon and into the fermenter. Will this be sufficient or should I do more?

Currently have an Oatmeal Stout and a California Common fermenting away. Belgian Dubbel bottled 3 weeks ago tasting good. Too good. It'll be gone by Christmas - or given away to guests.

Thats the curse of homebrewing - you give all the best stuff away and have to drink whats you've messed up!

I splash the wort out of the kettle tap into the FV which is fine IME - Siphoning might be sufficient if there's a bit of turbulence and disruption to the flow - I wouldn't gently siphon the wort into the bottom of the FV, think it needs a bit more motion.

Have one in the secondary atm using hops from my garden - bit of an experimental one as the IBUs were a total guess, and I'm not even 100% on which variety I was adding, so time will tell. Should get another one on this weekend for some Christmas bevvying.

You can pick up a little spray attachment that goes on the end of your siphon tube for a few pounds.

[url= https://www.wyeastlab.com/hb_oxygenation.cfm ]Wyeast[/url] have some basic info on their website giving stats for the main methods of oxygenation.

You're aiming for 10ppm. A siphon sprayer will give you 4ppm and shaking the carboy for 40s will give you 8ppm. I shake.

You can't get above 8ppm using any method other than pure o2 injection.

I'm going to get a brew on this Friday night - Belgian Witbier with Christmas spices. Aiming to be subtle with the flavours - not in yer face spicey.

Was going to use malt and torrified wheat but a brewer friend recommended not using 100% torrified as it smells like cat pee.

Any experience/advice for using spices and/or torrified wheat?

Also need to bottle a star anise stout - hoping for some subtle licourice but it's been in secondary far longer than I planned.

Cheers!

You can pick up a little spray attachment that goes on the end of your siphon tube for a few pounds.

That could be useful for winemaking. I had a problem with hydrogen sulfide in my grape wine - it seems to have been solved by racking it twice and giving it a really good splash into the demijohn.

Any experience/advice for using spices and/or torrified wheat?

Not sure on torrified wheat...but in terms of spices, grab a bottom of not too hoppy pale (either your own or bought), ideally with little flavour!

Add spices to the bottle and drink. Simple but gives you an idea of what to expect in the finished product and can highlight what works together and what does not.

Also, have a read at Radical Brewing (my favourite brewing book by far, brilliant read!), since he talks a lot about spice additions.

I've always use flaked wheat in a wit. Have used torrified in beers but only a small amount for head retention, probably not enough to make a difference to the taste. Never heard of any grain having a "cat wee" smell/taste although some hops apparently have this characteristic (not really the description I'd use though!)Was going to use malt and torrified wheat but a brewer friend recommended not using 100% torrified as it smells like cat pee.

He recommended pouring boiling water over a handful of the grain and see how it smells. Will report back . . .

Morning;

I have an Amazon voucher to use and was going to invest it in a homebrew kit.

Has to be amazon,so any improvement on this for an American IPA starter kit?

Thanks,Stuart

I think you could do a bit better than that tbh, doesn't seem to be offering more than you'd get if you just walked into a brew shop and bought stuff. I mean bottles in a starter kit isn't much of a feature - any serious drinker has a load of empties piled up in the recycling every week.Morning;

I have an Amazon voucher to use and was going to invest it in a homebrew kit.Has to be amazon,so any improvement on this for an American IPA starter kit?

I have a brew that's been sitting in the secondary for one month - well longer than planned (it had 1 wk in the primary). Does that sound excessive to folk? [it's just a normal pale ale]. Should really bottle it tonight, but it's a lot of effort if it's starting to deteriorate.

Try some. I'm sure it'll be fine. If it's not, you'll know. 🙂

It does sound excessive, but I've left beers for that long (or longer) due to business/laziness, and they've turned out alright!

I have a brew that's been sitting in the secondary for one month - well longer than planned (it had 1 wk in the primary). Does that sound excessive to folk? [it's just a normal pale ale]. Should really bottle it tonight, but it's a lot of effort if it's starting to deteriorate.

Assuming everything is sanitary, the only thing you might notice is diminished hop character, but at only 4 weeks in secondary it won't have changed much at all.

IMO though there's very, very little benefit to secondary for a pale (other than maybe additional clarity, but still not as good as cold crash or fining), and you introduce a number of potential problems by transferring. It's one of those techniques that the pros do and so it's made its way into the homebrewing world but it's actually not needed for us in most situations.

For a sub 5% pale with a chico strain yeast, I'd hold it cool until just after it hits FG and then slowly ramp up the temp over a couple of days to let it finish up. I leave those types of beers for about 2-3 weeks in primary, cold crash and then straight to bottle/keg.

Thanks - I'll get it done and see how it turns out.

Just bought some Corny Kegs 😀 £100 for three on ebay, then as usual with these things found a shop selling them for £90/3 whilst searching for disconnects etc!

To those of you who keg, am I right in thinking that all I need initially is

CO2

Regulator

Reinforced hose

Gas Disconnects

Combined tap/disconect

And (after initially pressurizing the keg to 10psi to seal the lid) I can leave it to secondary ferment and carbonate naturally in the corner of the kitchen, put it in the garage to cool and only hook upto the CO2 to serve? The full on Keezer setup with secondary regulators will have to come later, as paychecks allow.

--------------------------------------------------------------------------------

Entirely separate 2nd question.

The kegs are the result of now having enough space to play around in, so I've also now got space to build a cheap all grain setup, apart from following the £100 Brewery guide on instructables with a few tweeks. Does anyone have any pitfalls they've experienced to share? I'm skipping the BIAB stage and going straight from dry hopped kits because SWMBO didn't want it in the kitchen! Most looking forward to brewing some Imperial/double/west coast style IPA's, so big grain bills and a lot of hops, hence bigger buckets*.

Probably left this all a bit late to brew for Christmas (might squeeze a kit in), but at least I can ask for a lot of stuff from Santa!

*I did find some cheap 60l polypropylene buckets, but that might be a bit excessive!

Keep the cornie fill level to below the gas-in dip tube 🙂 Stops beer being forced into your regulator if you connect up a pressurised keg to a non-pressurised regulator (I know this from experience 😆 ). Or fit a check-valve on the gas-in line for belt and braces.

I have a brew that's been sitting in the secondary for one month - well longer than planned (it had 1 wk in the primary). Does that sound excessive to folk? [it's just a normal pale ale]. Should really bottle it tonight, but it's a lot of effort if it's starting to deteriorate.

I left my last brew in primary for 3 weeks (Woodforde's kit recommends 6 days!)due to life getting in the way, and it was absolutely fine. I transferred to a pressure barrel to batch prime it, then bottled. It has cleared far quicker than previous brews, and tastes pretty damn good. Don't know if it's a coincidence, but I'm going to brew this way in the future.

Presumably as long as it's sterile then it should be fine.

I've got 3 demijohns of wine on the go, they've been in secondary for 2 months now, primary for wine is a bit different, the grapes stay in the barrel for ~5 days to release the sugar/flavours and begin fermenting, then you syphon and strain it into demijohns to finish fermenting. There was still more un-fermented sugar in there when it went into secondary than in most wort's (and the yeast was in suspension). Leave it in primary too long and the grapes begin to impart off flavors (apparently they rot, but given the amount of Campden tablets that go into wine I'm not so sure that's possible!).

Time to bottle it and try it next week, need to judge if it's drinking wine or mulled wine to be given away as Christmas presents!

To those of you who keg, am I right in thinking that all I need initially isCO2

Regulator

Reinforced hose

Gas Disconnects

Combined tap/disconect

Regulator - keep an eye out for an old Coca Cola gas management board, they are just perfect for kegging. Multiple regs and tons of connections. They come up regularly on ebay.

Buy all new seals for your kegs (lid, post and dip tubes). They are cheap and depending on what has been stored in them, essential. For the sake of a couple of quid, replace them and start from a clean slate.

Get some PBW or bar keepers friend and a toilet brush (new) and give them a really good clean or three. I dumped my first kegged batch because even though I'd scrubbed and soaked for days, it still had residue from the syrup that was previously stored in it. Get a dip tube brush for the same reason.

And (after initially pressurizing the keg to 10psi to seal the lid) I can leave it to secondary ferment and carbonate naturally in the corner of the kitchen, put it in the garage to cool and only hook upto the CO2 to serve? The full on Keezer setup with secondary regulators will have to come later, as paychecks allow.

You could do that, but you'll need to have a think about your temperatures. co2 is more readily absorbed at lower temps so your carbonation will vary depending on where you put it.

You could do that, but you'll need to have a think about your temperatures. co2 is more readily absorbed at lower temps so your carbonation will vary depending on where you put it.

I was thinking for fermentation rather than carbonation, if the beer's in the keg with just enough to seal the lid, then most/all the CO2 from fermenting will stay in the liquid (like bottling)?

Might give forced carbonation a go for a very hopy IPA, but I'd rather do things 'right' rather than copy commercial methods to speed things up for brews that don't need to be so fresh.

Kegs are coming from a homebrewer, so should be clean.

I've got 3 demijohns of wine on the go, they've been in secondary for 2 months now, primary for wine is a bit different, the grapes stay in the barrel for ~5 days to release the sugar/flavours and begin fermenting, then you syphon and strain it into demijohns to finish fermenting. There was still more un-fermented sugar in there when it went into secondary than in most wort's (and the yeast was in suspension). Leave it in primary too long and the grapes begin to impart off flavors (apparently they rot, but given the amount of Campden tablets that go into wine I'm not so sure that's possible!).

Me too: one grape, one apple and one rhubarb, all from the garden. The rhubarb was a bit different - left to macerate dry in sugar for a few days, then the leached juice was transferred to a demijohn with the yeast added to start fermentation. The grapes were pressed to release the juice, then transferred to a demijohn with sugar, yeast & nutrient. Apple was fermented on the chopped fruit in a clean bucket before transferring: it's the least successful of the three, as I don't think I left it in primary long enough to get the flavour out of the fruit.

All three had grape concentrate and pectolase added, though the rhubarb has still thrown a haze and will need finings. I'll be bottling in the next week or so - I sampled them last night and the grape and rhubarb taste pretty good, with the apple probably heading for cooking wine.

I was thinking for fermentation rather than carbonation, if the beer's in the keg with just enough to seal the lid, then most/all the CO2 from fermenting will stay in the liquid (like bottling)?Might give forced carbonation a go for a very hopy IPA, but I'd rather do things 'right' rather than copy commercial methods to speed things up for brews that don't need to be so fresh.

Triggering that second fermentation in the bottle (by priming with additional sugar) [i]is[/i] carbonating the beer, so I just mean that you'll need to [url= http://www.brewersfriend.com/beer-priming-calculator/ ]adjust for temperatures[/url] when priming (e.g. the priming sugar addition is very different depending on whether you cold crashed or not).

Force carbing is a breeze though and you'll end up with a much clearer beer (particularly if you fine). I just hook mine up at serving pressure and leave for two weeks.

Now that you've got co2 and kegs, you can do closed co2 transfers from the carboy to the keg, meaning that your beer won't come in to contact with oxygen from when you start fermenting to the moment you pour yourself a glass. This has a HUGE impact on lighter styles...they all just taste so fresh and incredible! Basically all you are doing is using your co2 to push the beer from the carboy into the keg. I can post some pics of my set up. It's super easy and there's no faffing around with siphons etc.

Pics would be good, I presume that means you ferment in pressure barrels rather than buckets?

Do you oxygenate the wort before it goes in the fermenter then, or do you have to go mad with the yeast starter?

Just put a cheeky offer in on a Britvic gas management board on ebay and a post on freecycle for a chest freezer.............

I've worked my way through cheap kits + sugar, through brewing sugar, DME and various extracts and dry hopping to the point where my brew tastes good enough that if I give a few bottles away or serve it in a glass no one can guess which is home brewed and which is bought. But it still has a distinct (but not as strong as it was with Geordie/John bull style kits) homebrew 'tang', trying to figure out if it's the yeast being stressed or oxygen getting in during bottling.

But it still has a distinct (but not as strong as it was with Geordie/John bull style kits) homebrew 'tang', trying to figure out if it's the yeast being stressed or oxygen getting in during bottling.

What water are you using? I've seen suggestions that the tang is due to chlorine in mains water... half a crushed campden tablet being the solution. I tried that with my last brew and I can't detect a tang, but not exactly a scientific trial.

I've worked my way through cheap kits + sugar, through brewing sugar, DME and various extracts and dry hopping to the point where my brew tastes good enough that if I give a few bottles away or serve it in a glass no one can guess which is home brewed and which is bought. But it still has a distinct (but not as strong as it was with Geordie/John bull style kits) homebrew 'tang', trying to figure out if it's the yeast being stressed or oxygen getting in during bottling.

I'll post a few pics of my set up tonight.

If I'm using liquid yeast then yes, I oxygenate/aerate the wort before pitching. Nothing fancy, so I'm getting no more than 8ppm (the target is closer to 10ppm, but I'm not yet convinced by blasting with pure o2 since too much can be just as harmful as not enough).

Those gas management boards are great, I managed to pick one up for £50 and it has been faultless.

Re the homebrew tang, there are a few things that could be causing it, but most likely it's all of them together. I've heard that DME can produce a distinctive taste and depending on the yeast you use (and how you use it!), that could exacerbate it.

Everyone knows about temp control being important, and it is, but equally important is pitch rate and yeast health.

If you're using dry yeast it's not so difficult, since it's far less reliant on good aeration. But unless you're properly hydrating the yeast before pitching you are losing up to half of the viable cells...meaning that even in a 1.050 beer you'd be underpitching, leading to stressed yeast. The companies who make the kits and the yeast don't like to make too big of a deal about the efforts you need to go to to ensure good yeast health because part of their marketing strategy is ease of use.

For liquid yeast you almost always need a starter and you definitely need good aeration. It's much more fickle than dry yeast, but you get an incredible amount of choice.

But above all, IME, it's absolutely everything together that makes a "flawless" beer. I've brewed beers with simple ingredients, simple process and a single pack of rehydrated US05 that have been judged in the high 30's and low 40's by BJCP...so it's nothing fancy that makes the difference.

For me, the key things to focus on are:

Proper pitch rate (using an online calculator) of healthy yeast

Solid temp control during fermentation, with the ability to ramp up the temp after the end of active fermentation to allow the yeast to finish up

Limited exposure to oxygen after fermentation

Fresh ingredients (ie try to avoid using grain that was crushed a month ago)

Basic attention water chemistry really helps, particularly with light/hoppy beers (this was the thing that took my IPAs from good to great IMO)

Fast chilling times

Cleanliness obviously

+1 to rehydrating dried yeast prior to use. This also has the advantage of allowing you to verify that the yeast is "good" prior to pitching i.e. it's showing some signs of life. Otherwise you won't know until 24 hours or so later.

I brewed an attempt at a Tring "Sidepocket for a Toad" clone on Saturday, fermenting away like a good un in my temp controller brew fridge* currently.

* in heating mode with a 45w tubular heater controlled by an ebay temperature controller unit.

Might have to give this a go. In the SE, so seriously hard water, although we've just moved house and supplier from Southern to Thames which seems to be much softer (Southern would completely block a showerhead in a matter of weeks).Basic attention water chemistry really helps, particularly with light/hoppy beers (this was the thing that took my IPAs from good to great IMO)

Might have to give this a go. In the SE, so seriously hard water, although we've just moved house and supplier from Southern to Thames which seems to be much softer (Southern would completely block a showerhead in a matter of weeks).

If you want to make it easy for yourself (balancing water yourself isn't that easy), pay Murphy and Sons £20 and have them analyse your water.

You'll get a proper report back (so no guessing from out of date water company reports) and they provide suggested adjustments for different styles.

On top of that, the lab manager is a home brewer and wonderfully helpful if you have queries.

Water makes up the main ingredient in your beer, so it's a good place to start!